Medical production line conveying device

A technology of conveying device and production line, which is applied in the directions of packaging, packaging machine, transportation and packaging, can solve the problems of unfavorable medicine bottle box transmission, affecting the coding of medicine bottle boxes, etc., and achieves the effect of good transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the realization technical means, creation features, achievement goals and effects of the present invention easy to understand and understand, the present invention will be further described below with reference to the specific drawings.

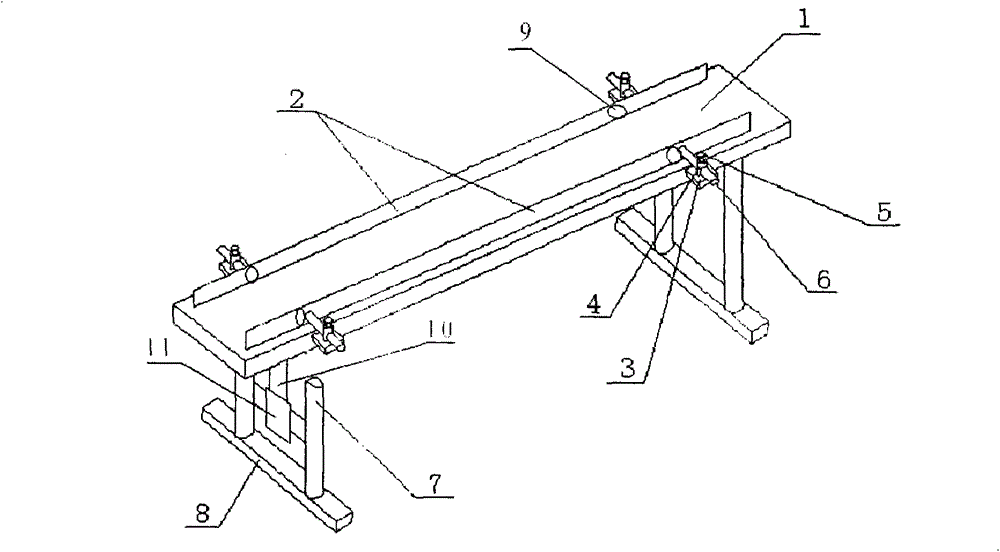

[0010] like figure 1 As shown, a conveying device for a pharmaceutical production line includes: a conveying plate 1, a support leg 7, a fixing clip, a laser counter 9, and a position adjusting cylinder 11. The conveying plate 1 is provided with support legs 7 at both ends, which are located on the same side of the conveying plate 1. The two supporting legs 7 at the ends are connected by a horizontal plate 8. A positioning cylinder 11 is arranged at the bottom of one end of the transmission plate 1. A positioning shaft 10 is installed on the positioning cylinder 11, and the positioning shaft 10 is fixed on the bottom end of the transmission plate 1. The adjusting cylinder 11 drives the adjusting shaft 10 to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com