Crawler type substation patrol robot based on hub motor

A technology for inspection robots and hub motors, applied in the field of robotics, can solve the problems that the structure of the robot cannot be changed again, the experimental equipment cannot be installed, and the structure is complex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

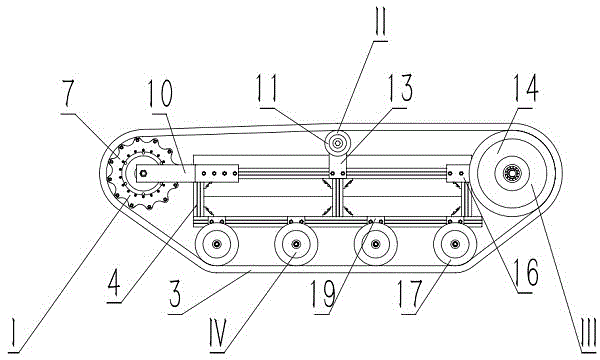

[0019] see Figure 1~Figure 5 , a crawler-type substation inspection robot based on hub motors, including: a connecting frame (1), an electrical box (2), and two driving systems with the same structure distributed on the left and right sides, characterized in that: the left and right two The side drive system is connected into one body through the connecting frame (1), and the connecting frame (1) is fixedly connected with the two support frames (4) in the two driving systems through relative translation adjustment, so that the position can be freely translated and slid to adjust; The electrical box (2) is fixed on the connecting frame (1); the motor (9) in the driving system adopts a hub motor, omitting transmission components, and simplifying the structure.

Embodiment 2

[0021] This embodiment is basically the same as Embodiment 1, especially as follows:

[0022] The drive system includes: drive track (3), support frame (4), drive wheel drive mechanism ( ), supporting mechanism of supporting sprocket ( ), guide wheel support mechanism ( ) and roller support mechanism ( ), and the front and rear ends of the support frame (4) are respectively equipped with a guide wheel support mechanism ( ) and drive wheel drive mechanism ( ), while the upper and lower parts of the middle are respectively equipped with supporting sprocket supporting mechanisms ( ) and roller support mechanism ( ), the transmission track (3) is wrapped on their periphery. The drive wheel drive mechanism ( ) includes the outer column of the engagement column (5), the inner column of the engagement column (6), the flange plate (7), the spoke hole support (8), the motor (9) and the motor support frame (10), the outer column of the engagement column (5) Installed on...

Embodiment 3

[0024] Such as Figure 1 to Figure 3 As shown, the crawler substation inspection robot based on hub motors includes: connecting frame (1), electrical box (2), and two drive systems distributed on the left and right sides. The structure of the left and right two driving systems is the same, including: transmission crawler belt (3), support frame (4), drive wheel drive mechanism, support sprocket support mechanism, guide wheel support mechanism, roller support mechanism. The electrical box (2) is fixed on the connecting frame (1). The drive wheel drive mechanism ( Figure 4 ) includes: engagement column outer column (5), engagement column inner column (6), flange plate (7), spoke hole support (8), motor (9), motor support frame (10), wherein the engagement column The outer column (5) is installed on the inner column (6) of the engaging column, and the inner column (6) of the engaging column is installed on the flange plate (7), and the flange plate (7) connects with the motor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com