Welding machining device

A processing device and welding trolley technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as difficult to guarantee dimensional accuracy, weldments, and accuracy, so as to ensure processing accuracy and work High efficiency, reduced strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

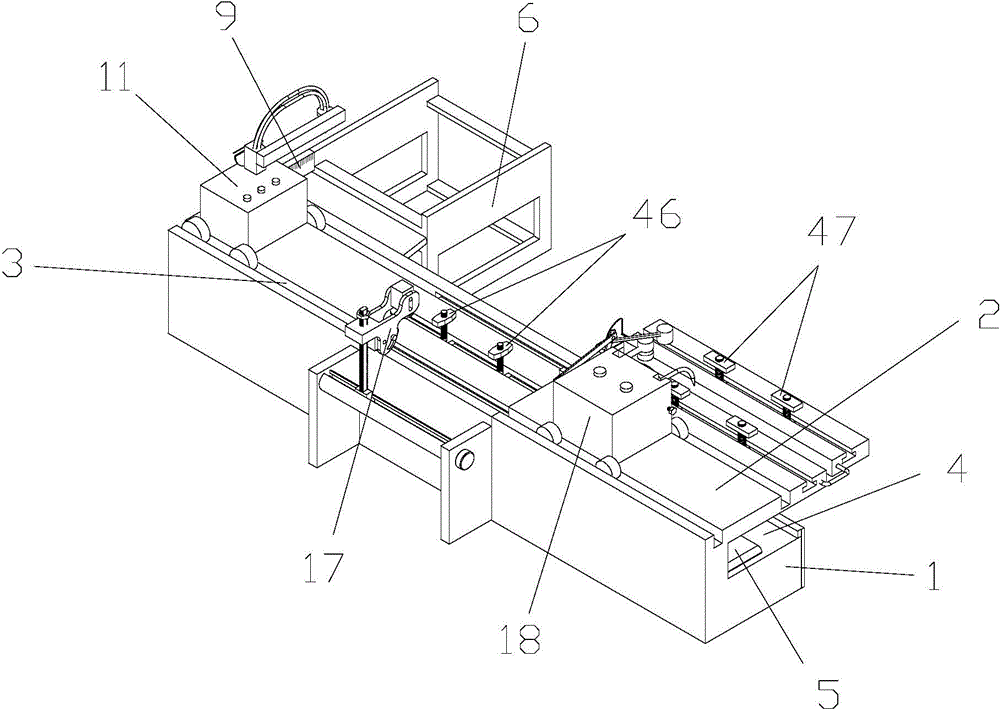

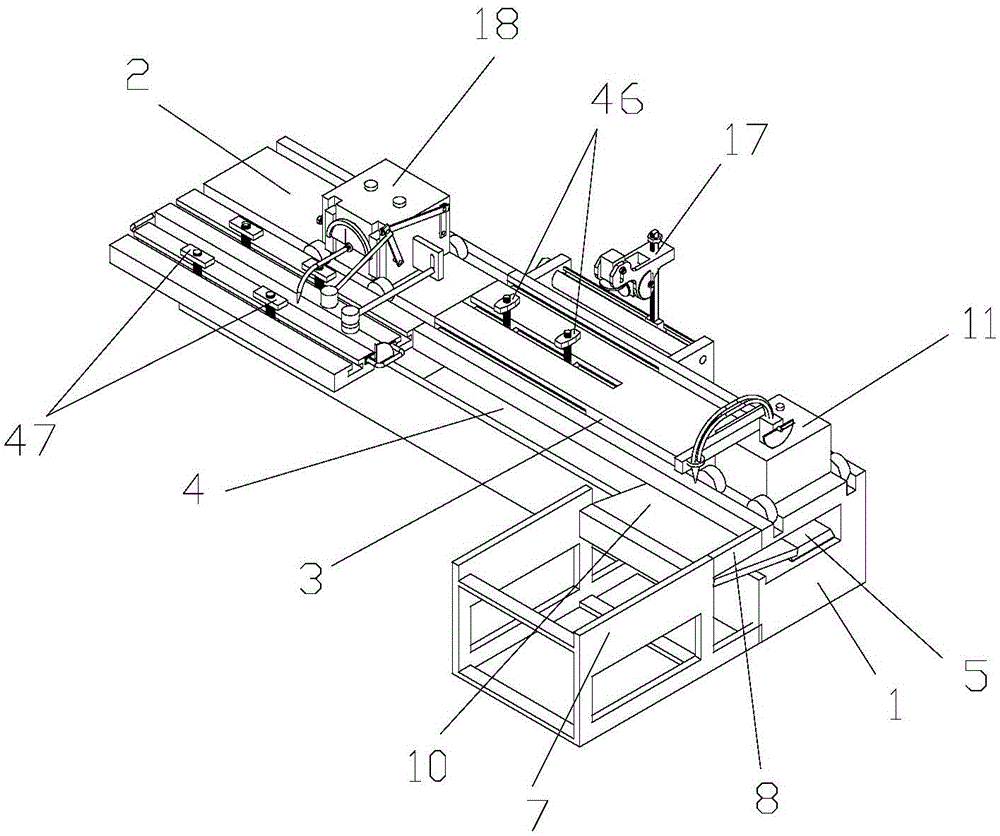

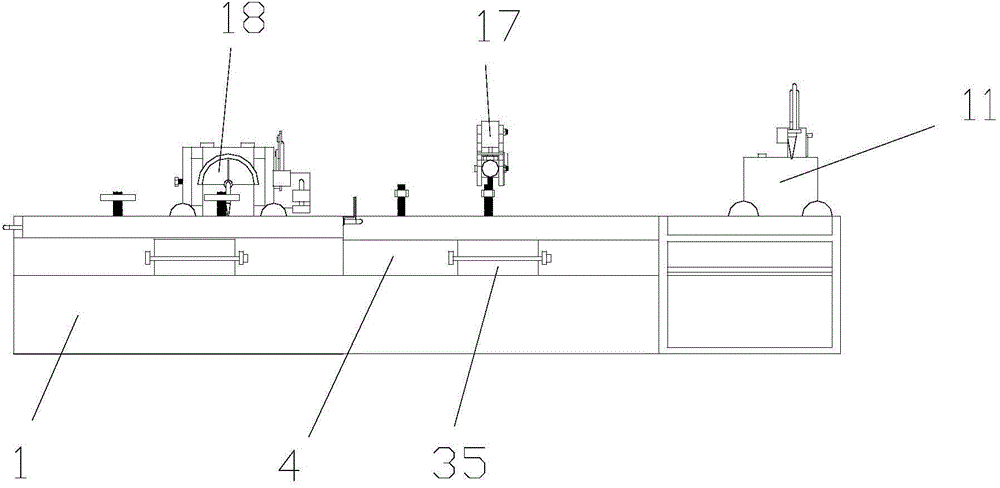

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] With reference to accompanying drawing: this welding processing device among the present embodiment comprises frame 1, is provided with console 2 on frame 1, is provided with first chute 3 on console 2, is provided with on frame 1 and is located in the operation table. The conveying groove 4 below the table 2, the conveying groove 4 is provided with a conveyor belt 5, the upper part of the conveying belt 5 is provided with a push plate 35, the push plate 35 is fixed on the inner wall of the conveying groove 4, and the starting point of the frame 1 is provided with a feeding positioning device 6. The feeding positioning device 6 includes a support frame 7 whose height is lower than that of the operating table 2. A connecting plate 8 is connected between the supporting frame 7 and the operating table 2. A scale 9 is arranged on the connecting plate 8. The supporting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com