Combined mold for processing outer tube of thermos cup and new process for processing thermos cup

A combined mold and thermos cup technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of mold cost, machine cost, high personnel cost, low production efficiency, multiple sets of molds, etc., and achieve reduction The number of molds used, the effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

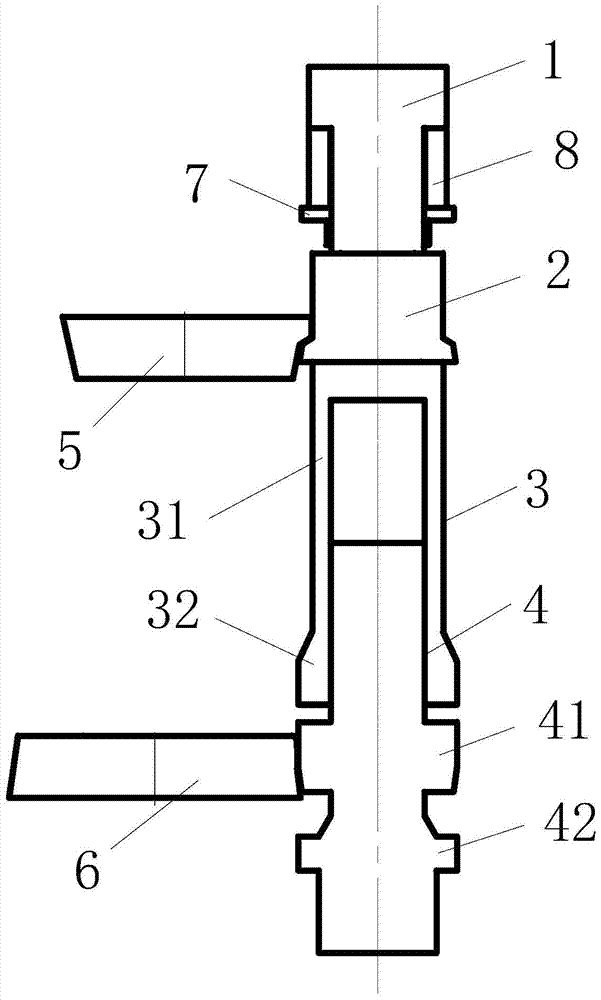

[0027] Such as figure 1 As shown, a combination mold for processing the outer tube of a thermos cup includes a back top 1, a die head 2, a spring clamp 3, and a lower die 4 arranged in sequence; wherein, the back top 1 is connected with the shaft hole of the die head 2; the die head 2 One end of the spring clamp 3 is bolted; the other end of the spring clamp 3 is connected with the 4 shaft holes of the lower mold. Specifically, the back top 1 is a step shaft, and the front end shaft of the back top 1 step shaft is connected with the shaft hole of the die head 2; the die head 2 is a step shaft with a through hole in the middle, and the front end of the step shaft of the die head 2 is connected to the back top 1 The front ends of the step shafts are arranged oppositely; there is a through hole in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com