Efficient solid-liquid separating centrifugal machine

A solid-liquid separation and centrifuge technology, applied in the field of centrifuges, can solve the problems of reducing solid discharge, liquid flow disturbance, affecting separation effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

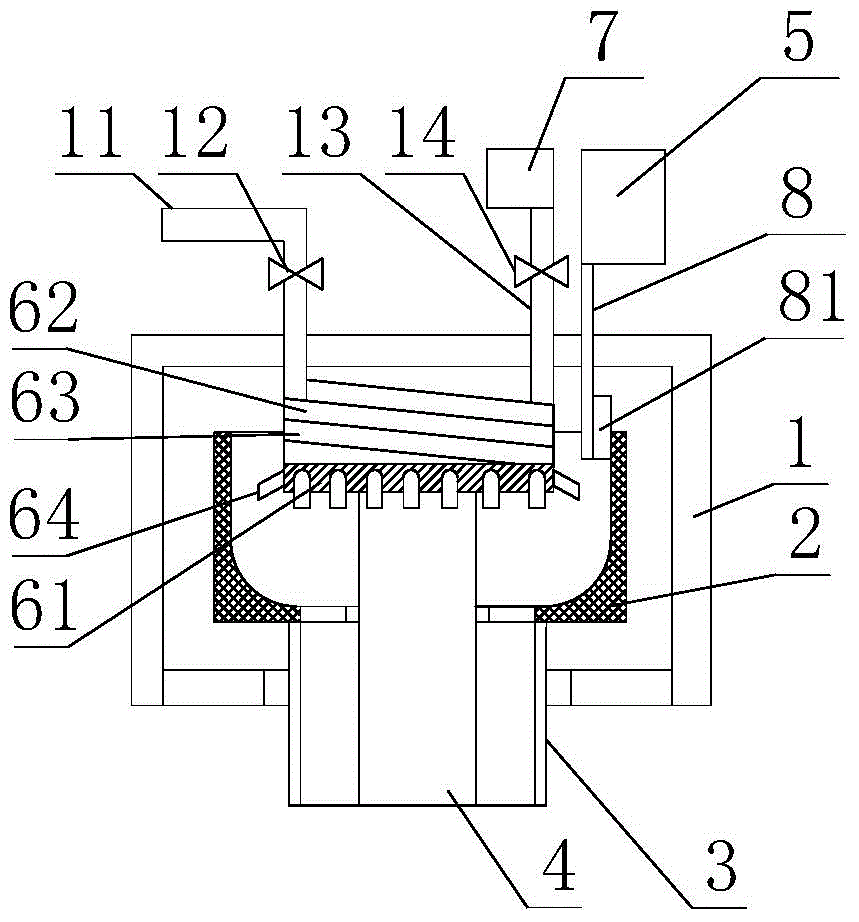

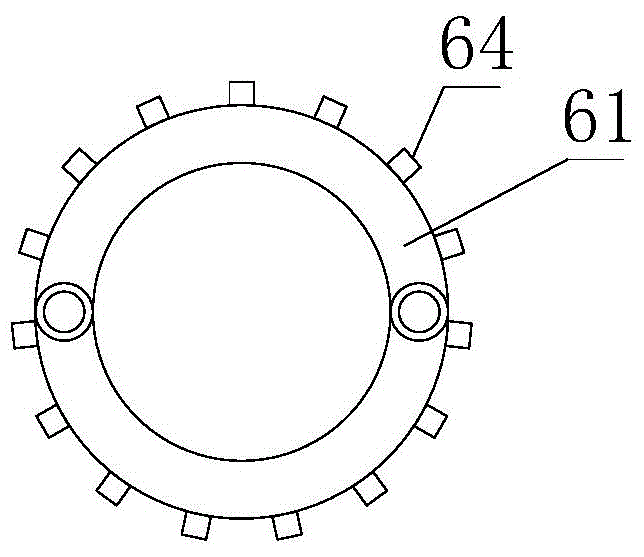

[0015] Such as figure 1 and 2 as shown, figure 1 It is a structural schematic diagram of a high-efficiency solid-liquid separation centrifuge proposed by the present invention, figure 2 for figure 1 A schematic top view of the annular jet in .

[0016] refer to figure 1 and 2 , a high-efficiency solid-liquid separation centrifuge proposed by the present invention, comprising: a casing 1, a drum 2, a discharge cylinder 3, a first drive device 4, a second drive device 5, a flow guide mechanism, an air injection mechanism 7, a scraper rod 8;

[0017] There is a cavity inside the casing 1, the bottom of the cavity has a first outlet for discharging solids and a second outlet for discharging liquid, the top of the casing 1 is provided with a liquid inlet and an air inlet, and the liquid inlet is provided with The liquid inlet pipe 11 is provided with a first valve 12, the air inlet is provided with an air inlet pipe 13, and the air inlet pipe 13 is provided with a second va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com