A single-stage multi-output LED power supply constant current drive circuit

A technology of LED power supply and multiple output, which is applied in the layout of electric lamp circuit, electric light source, light source, etc., can solve the problems of high cost, low overall benefit, temperature rise, etc., to improve efficiency, simplify LED power drive circuit, and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

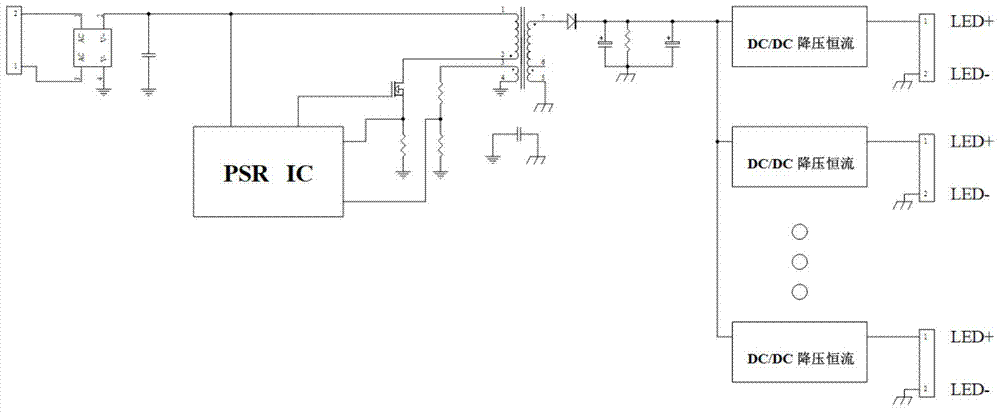

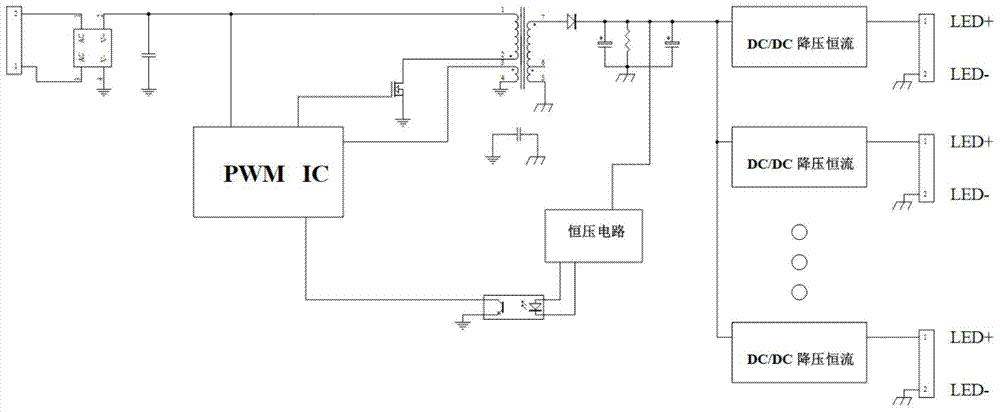

Problems solved by technology

Method used

Image

Examples

Embodiment 1

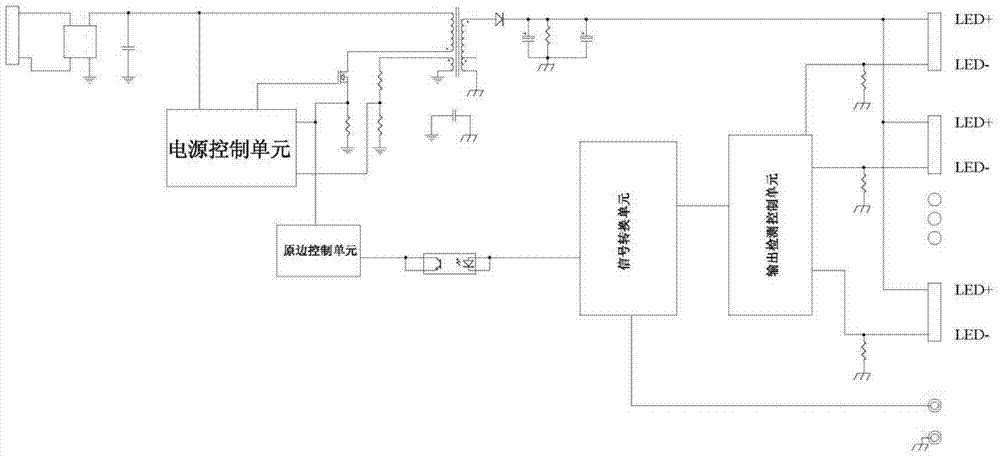

[0087] Please refer to Figure 4 , 5 And 8, embodiment one of the present invention is:

[0088] A primary-side feedback single-stage multi-output LED power supply constant current drive circuit, including a power supply module, a power supply control module, a transformer, a primary-side control module, a PWM signal generation module, an output detection module, and at least two LED load access channels ;

[0089] The output detection module includes an output detection circuit and a VCC power supply circuit connected in sequence;

[0090] The PWM signal generation module includes a dimmer access terminal, an analog voltage generation circuit, a 0-10V conversion PWM circuit and a PWM transmission circuit connected in sequence;

[0091] The primary side control module includes an output current adjustment circuit and an output voltage control circuit connected to each other;

[0092] The power supply module and the power control module are respectively connected to the prima...

Embodiment 2

[0094] Please refer to Figure 5 and 8 , on the basis of embodiment one, embodiment two of the present invention is:

[0095] The output detection module includes an output detection circuit and a VCC power supply circuit connected in sequence; specifically:

[0096] Described output detection circuit comprises resistance R46, R63, R71, R45, R47, R36, electric capacity C27, C21, C20, C24, C22 and photoelectric isolator IC7; Concrete working principle is as follows:

[0097] When the LED light string is connected to the LED load and connected to the channel LED1+, LED1-, there will be a current through R36, and R36 will generate a voltage through R46 to the third pin IN+ and the second pin of the op-amp of the photoelectric isolator IC7. The set detection reference voltage is compared, and a low level is output after the comparison, telling the PWM signal generation module that the first LED load access channel is connected to the LED light. Resistor R63 plays a role in acce...

Embodiment 3

[0112] Please refer to Figure 5 and 8 , on the basis of embodiment one, embodiment three of the present invention is:

[0113] The PWM signal generating module also includes an opening and closing control module, and the opening and closing control module is respectively connected to the primary side control module and the PWM signal generating circuit of the 0-10V conversion PWM circuit;

[0114] The opening and closing control module includes resistors R67, R66, R70, R64, R65, R78, R73, R76, R47, R63, photoelectric isolator IC4, capacitor C55 and transistor Q8. R64, R65, R78 and IC4 form the reference 1.0V; the switching voltage signal is taken from the input "+" terminal of the third-stage operational amplifier circuit, that is, the IN3+ pin of integrated IC3, and the voltage is compared with the reference 1.0V after passing through R67, R66 and R70 , when it is lower than 1.0V, the third-stage circuit outputs a low level, drives the triode Q8 to conduct through R76 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com