Composite diaphragm, preparation method thereof, and lithium ion battery

A technology of composite diaphragm and diaphragm, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problems of high dispersion and difficult dispersion, reduce surface energy, improve ionic conductivity, and high rate performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The embodiment of the present invention provides a method for preparing a composite diaphragm, which includes the following steps:

[0014] S1, preparing nano barium sulfate modified with lithium carboxylate groups on the surface;

[0015] S2, preparing a composite gel; and

[0016] S3, composite the composite gel and the diaphragm base material to obtain a composite diaphragm.

[0017] Specifically, this step S1 includes:

[0018] S11, adding a solution formed by dissolving lithium carboxylate in an organic solvent to a soluble barium salt aqueous solution, and mixing to form a first solution;

[0019] S12: Provide a soluble sulfate aqueous solution with a pH value of 8-10, and add the soluble sulfate aqueous solution to the first solution to react to generate a precipitate;

[0020] S13, separating the precipitate, washing with water, and drying to obtain nano-barium sulfate whose surface is modified with lithium carboxylate groups;

[0021] In this step S11, the lithium carboxyla...

Embodiment (

[0052] Example (1) Preparation of nano barium sulfate

Embodiment 1

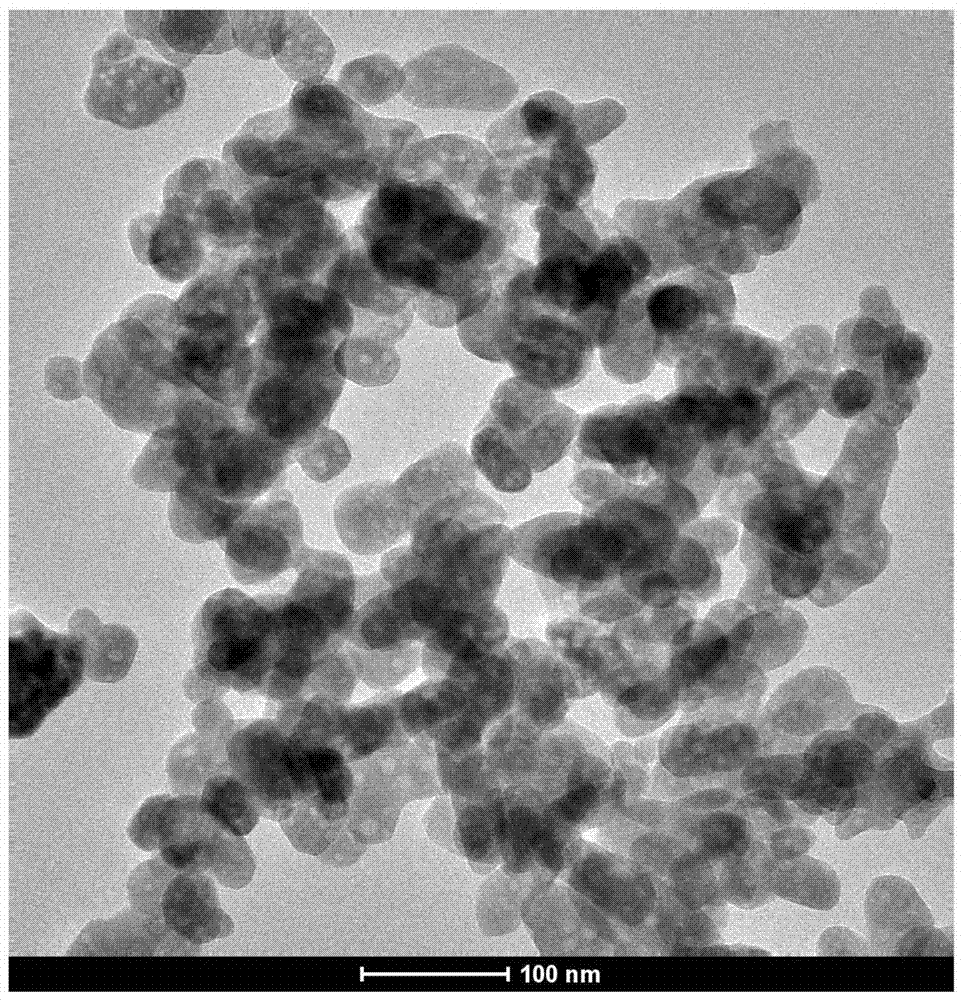

[0054] The solution formed by dissolving 0.01g lithium oleate in 50ml anhydrous methanol is added to 50ml, 0.5mol / L barium chloride solution, and uniformly mixing for 20 to 30 minutes to form a mixed solution; add 50ml, 0.5mol / L The sodium sulfate solution of L is adjusted to a pH value of 8-9 with ammonia water, and is slowly added to the above mixed solution, and the precipitate is obtained by centrifugal separation. The precipitate was washed 3 times in deionized water, and finally dried in a vacuum oven at 80° C. to obtain nano barium sulfate modified with lithium carboxylate groups. See figure 1 The particle size of the nano barium sulfate particles is relatively small, about 30 nm to 50 nm, a certain gap is formed between the nano barium sulfate particles and the particles, and each nano barium sulfate particle contains mesopores. It is 6nm-10nm. The specific surface area of the nano barium sulfate is about 19.9m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com