Valve flow measuring system

A technology for measuring system and valve flow, which is used in measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve the technical performance and quality requirements of valve products without in-depth research and without good testing equipment. , backward research and development capabilities, etc., to achieve the effect of enhancing core competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

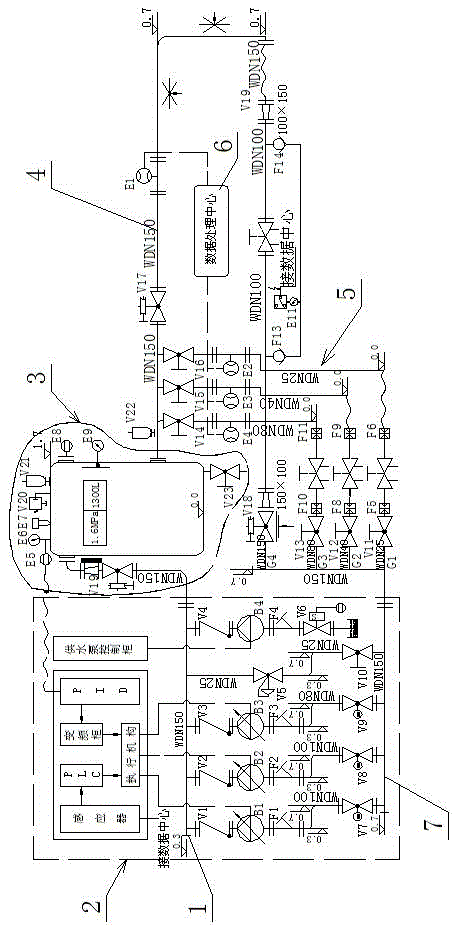

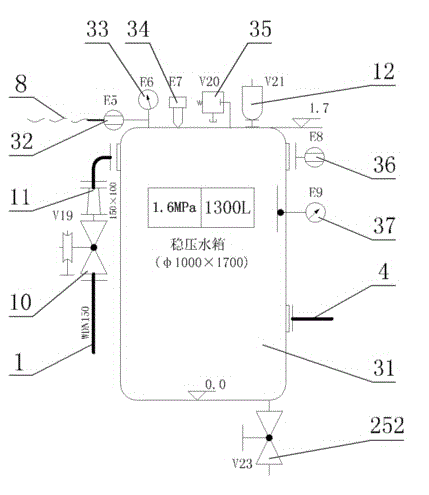

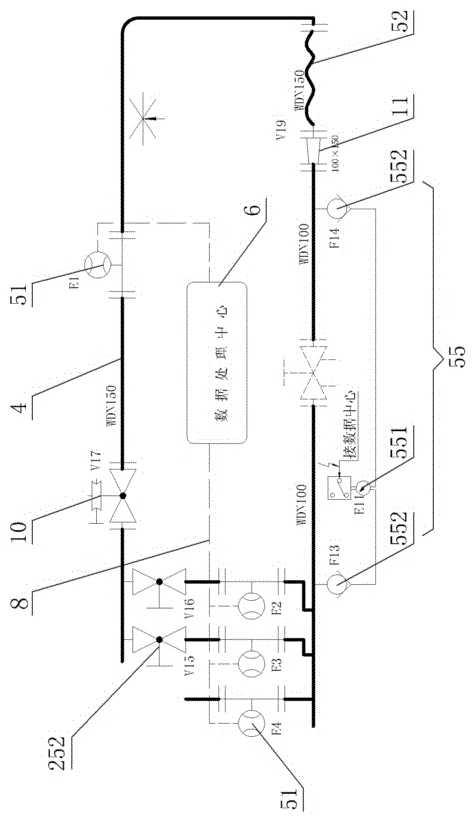

[0022] Such as Figure 1~Figure 5 As shown, 1. main water inlet pipe, 2. water pump control system, 21. frequency conversion water pump control cabinet, 211. sensor, 212. PLC controller, 213. actuator, 214. frequency conversion cabinet, 215. PID controller, 22 .Water supply pump control cabinet, 23. Frequency conversion water pump branch pipe assembly, 231. Electric ball valve, 232. Filter, 233. Frequency conversion water pump, 234. Check valve, 24. Solenoid valve branch pipe assembly, 241. Solenoid valve, 242. Liquid level Sensor, 243. Circulating pool, 25. Diverting pipeline, 251. Dynamic balance valve, 252. Handle ball valve, 3. Stabilized water tank system, 31. Stabilized water tank, 32. Pressure sensor, 33. Pressure gauge, 34. Liquid level sensor, 35. Unloading valve, 36. Hydraulic gauge, 37. Thermometer, 4. Main connecting pipe, 5. Valve test pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com