Rectangular low-frequency vibration calibration console with magnetic field tracking compensation and symmetric excitation on both ends of double magnetic circuits

A technology of tracking compensation and low-frequency vibration, which is applied in vibration testing, fluid using vibration, testing of machine/structural components, etc., can solve problems such as difficult assembly accuracy, magnetic circuit influence, poor compensation effect, etc., to ensure processing The effect of assembly accuracy, high air gap magnetic induction intensity, and convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

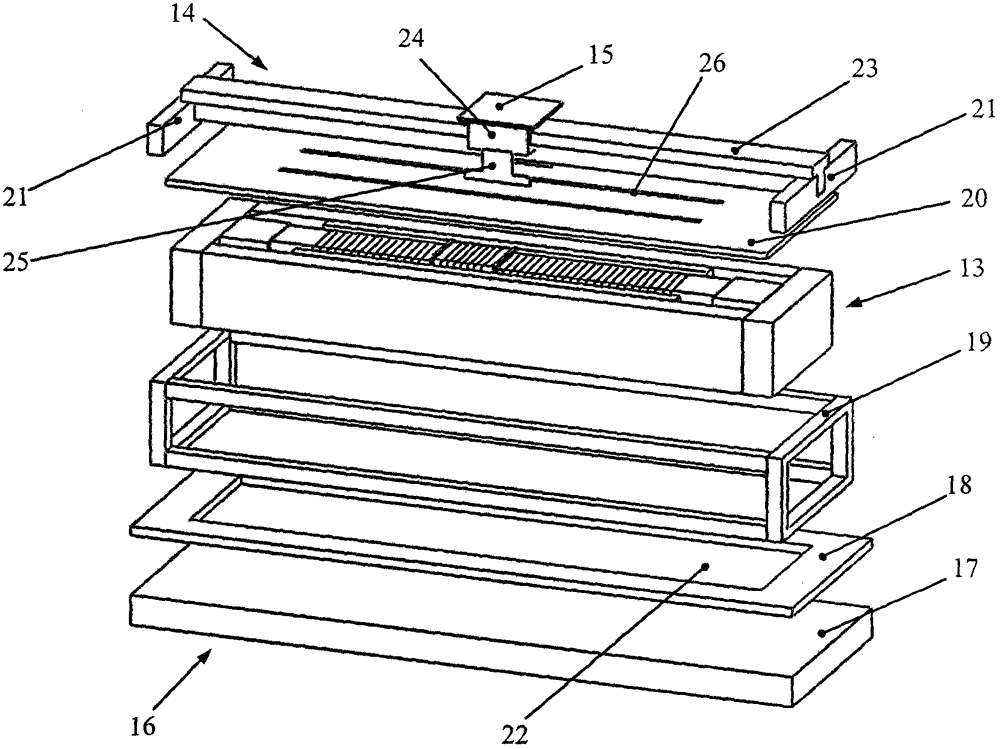

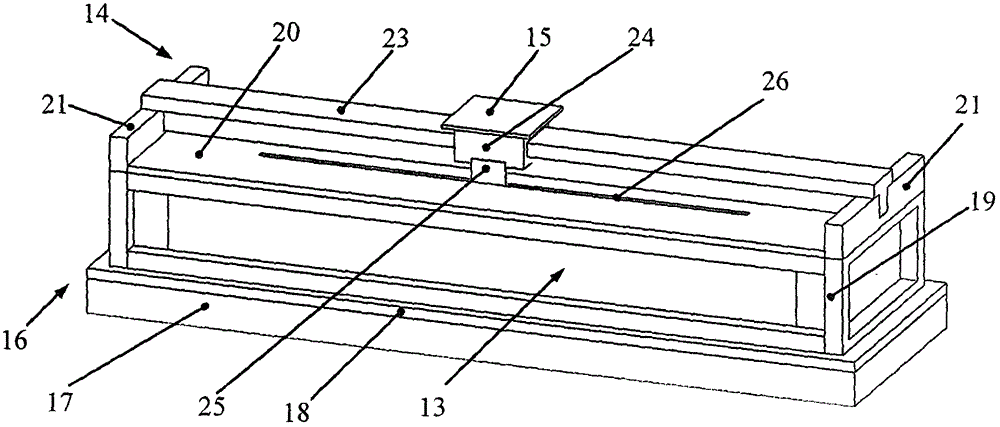

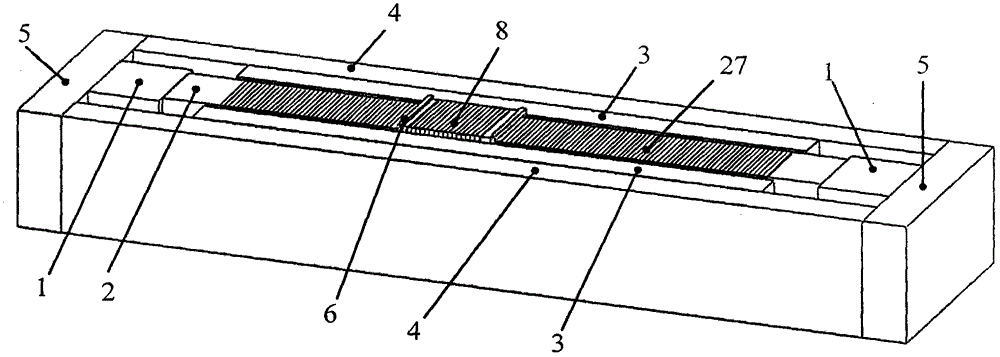

[0039] The specific implementation manner of the present invention will be described in detail below with reference to the accompanying drawings, and examples will be given.

[0040] A rectangular low-frequency vibration calibration platform with symmetrical excitation at both ends of a dual magnetic circuit for magnetic field tracking compensation, which is composed of a base 16, an electromagnetic drive structure 13, a static pressure air flotation guide rail 14, and a workbench 15. The electromagnetic drive structure 13 and the static pressure air flotation The guide rail 14 is installed on the base 16 in an axis-parallel manner, and the workbench 15 is installed on the upper surface of the sliding sleeve 24 in the static pressure air bearing guide rail 14. The base 16 is composed of a bottom plate 17, a lower transition plate 18, a frame 19, The upper cover plate 20 and the rail support member 21 are stacked and installed from bottom to top. The electromagnetic drive struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com