High temperature fire zone blasting device and high temperature fire zone blasting method

A fire zone, high temperature technology, applied in the high temperature fire zone blasting device and the high temperature fire zone blasting field, can solve the problems of blasting hole temperature rise, potential safety hazards, restrictions, etc., to avoid potential safety hazards, simple construction operations, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

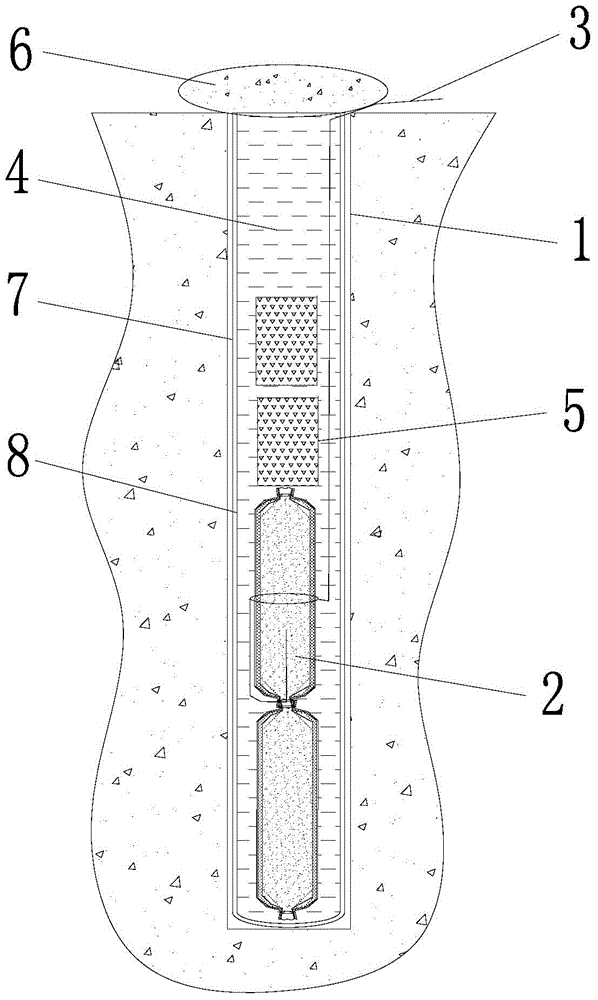

[0031] A high-temperature fire area blasting device, comprising a blasthole 1, explosives 2 and a detonating material 3 for detonating the explosive, and also includes a casing arranged in the blasthole, a liquid 4, a bagged plug 5 and a The orifice plug 6 for blocking the orifice of the gun hole; the liquid is injected into the casing, the explosive is soaked in the liquid, and the bagged plug is placed above the explosive and soaked in the liquid , A spare liquid area is formed between the bagged plug and the orifice plug. The orifice plug is a sandbag, the liquid is water, and the explosive is an emulsion explosive.

[0032] The casing can store the liquid in the blast hole, and the liquid can keep the explosive and the detonating material in an environment that does not exceed the temperature of the water bath for a long time, and the bagged plug is used for fast uncoupling plugging And to prevent the explosive from rising after being heated, the orifice plug is used to p...

Embodiment 2

[0040] A high-temperature fire zone blasting method, comprising the following steps:

[0041] Step 1: Drilling, inspection and temperature measurement;

[0042] Step 2: Prepare explosives, detonating materials, sleeves, bagged plugs and orifice plugs in advance at each gun port;

[0043] Step 3: Quickly lower the casing into the blast hole after wetting it, and quickly inject liquid into the casing;

[0044] Step 4: Quickly fill the explosives and detonating materials into the casing filled with liquid and lead the detonating materials to the ground;

[0045] Step 5: Put a bagged plug in the casing after the powder roll is loaded to prevent the explosive from rising after being heated and keep 3.5m of liquid on the top of the bagged plug;

[0046]Step 6: After all the blastholes have been constructed according to steps 2 to 5, the periphery of the blast area should be guarded, and all irrelevant personnel should be withdrawn, leaving only the blasters to work on the network,...

Embodiment 3

[0051] The explosive is No. 2 rock emulsion explosive (hereinafter referred to as the emulsion explosive), which has a diameter of 110mm and a length of 400mm; the sleeve is a fire hose, which is flexible, and its inner diameter is 136mm, and its length is cut according to the depth of the blast hole , the liquid barrier layer of the fire hose is made of PVC, which will not be damaged by high temperature burning under the condition of water, and the thickness is 0.3mm; the fabric layer of the fire hose is made of polyester, which is in the inner layer of the fire hose It can withstand high temperature below 400°C when it is filled with water; the diameter of the blast hole is 140mm, and its temperature range is 60°C-400°C; the bagged blockage is columnar, with a diameter of 110mm and a length of 500mm; the liquid is water, Its specific heat capacity is 4.2×10 3 J / (kg·℃), the boiling point is about 100℃; the detonating cord is the detonating cord, and the length is 12m; The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com