Monitoring system of dispersive printing and dyeing device

A technology of printing and dyeing equipment and monitoring system, which is applied in the field of automatic monitoring, can solve problems such as difficult temperature and pressure adjustment, and achieve simple structure, long communication interval, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

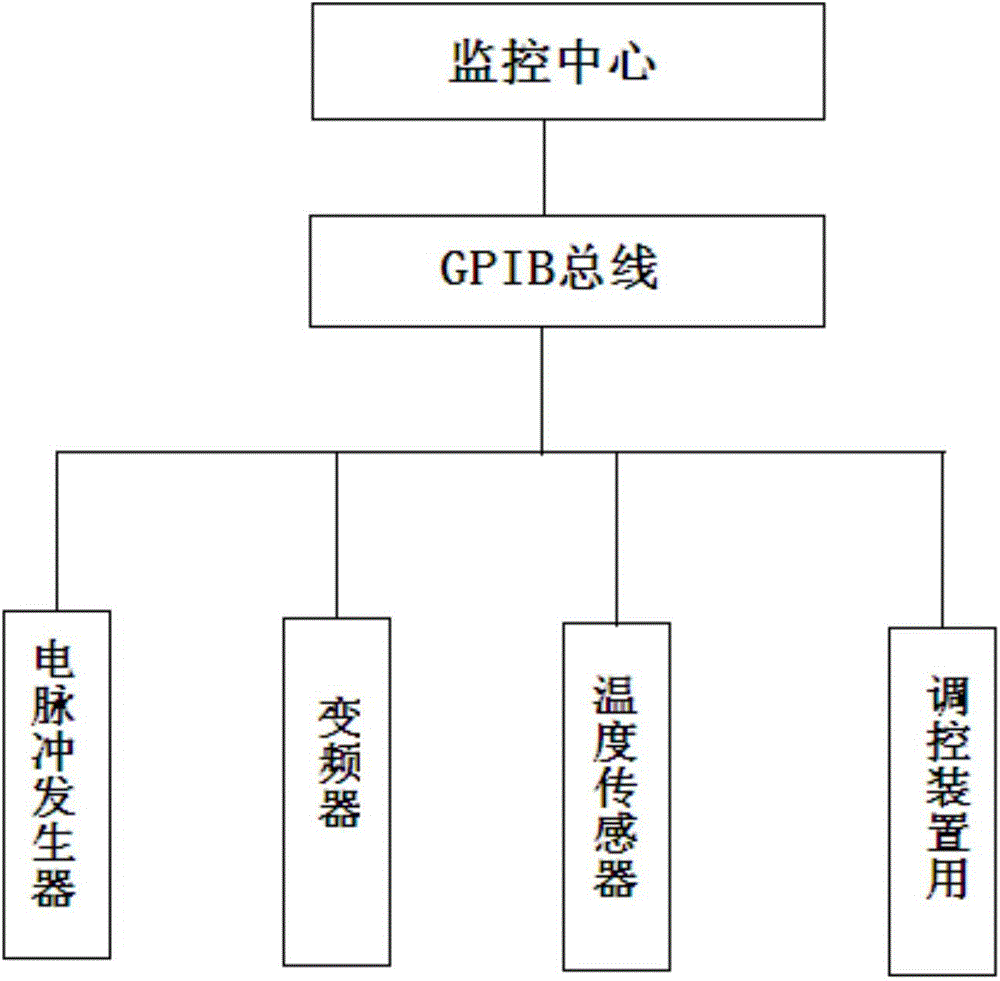

[0017] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0018] Such as figure 1 As shown, a monitoring system for distributed printing and dyeing equipment includes a plurality of sub-detection devices connected to a remote server terminal through a GPIB bus, and a control device corresponding to the sub-detection devices one by one. A photoelectric pulse generator for rotating speed, a temperature sensor for real-time detection of the temperature of the oven, the control device includes a microcontroller module and a regulator connected to it for adjusting the temperature of the oven, and a frequency converter for adjusting the speed of the motor; A photoelectric pulse generator and a temperature sensor are connected to the microcontroller module.

[0019] Wherein, the microcontroller module adopts AVR series single-chip microcomputer, the chip model of the photoelectric pulse generator is SD / GMC7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com