Corrosion process for anode aluminum foil with tunnel branched holes for aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and tunnel branches, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., to achieve the effect of obvious features, short steps and less harmful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

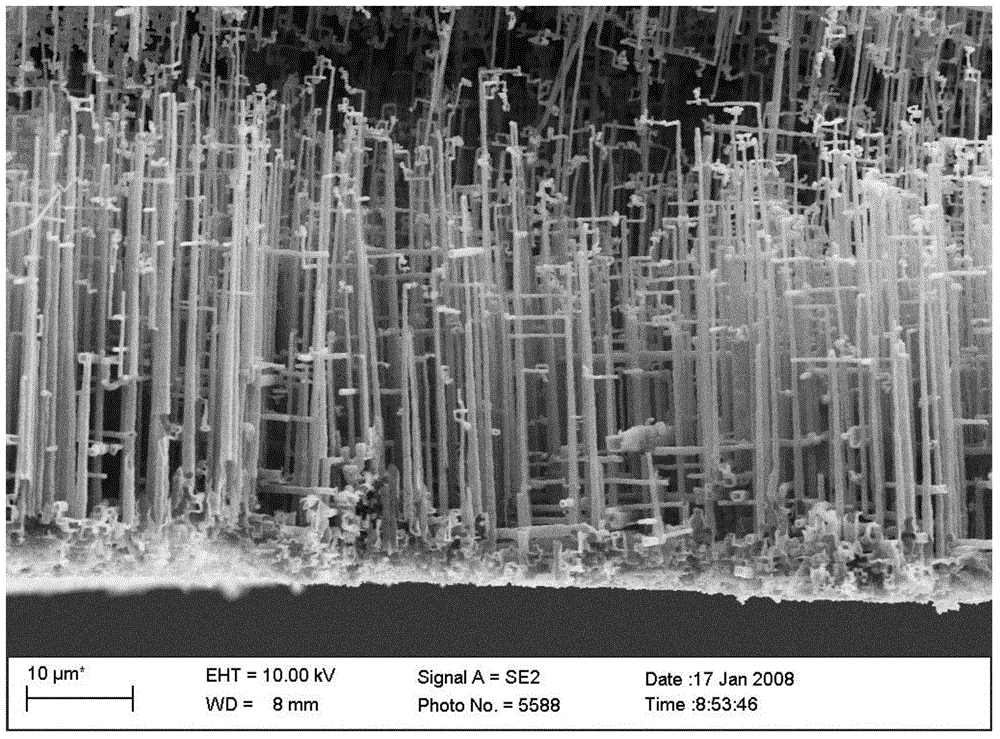

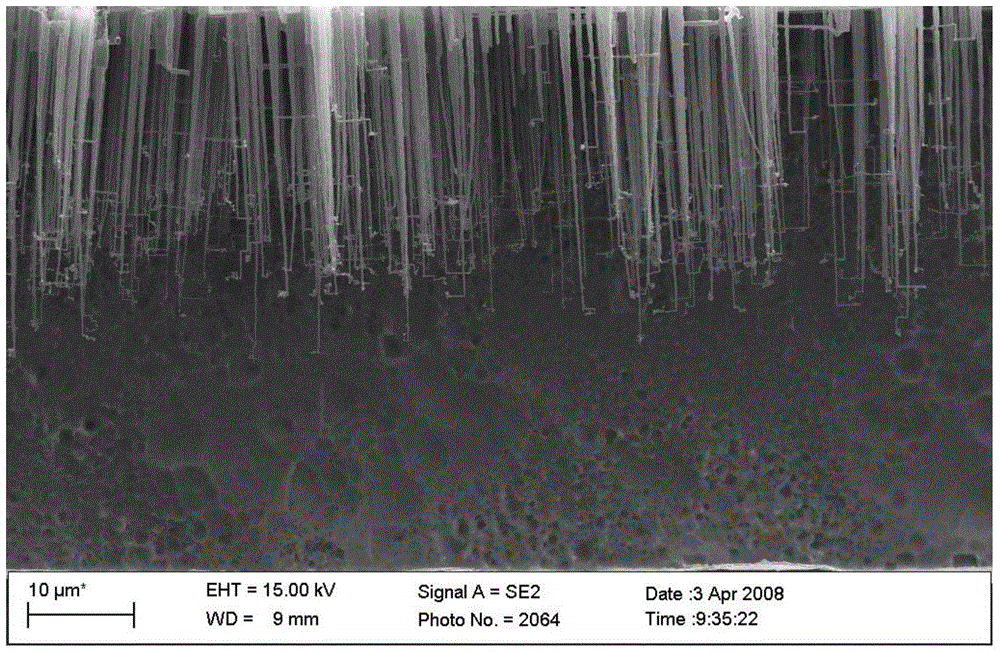

Image

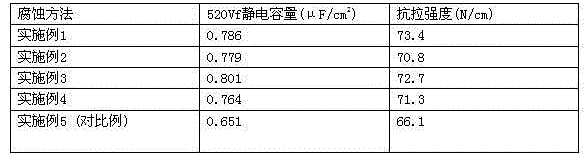

Examples

Embodiment 1

[0038] The thickness of the aluminum foil is 80μm. After the aluminum foil is pretreated, it is subjected to primary pore corrosion, and the pore current density is 100 mA / cm 2 , The hole electricity density is 20C / cm 2 ; Rinse with pure water and put it into a neutral salt solution containing additives for intermediate corrosion, the current density is 150 mA / cm 2 , The power density is 10C / cm 2 ; After cleaning with pure water, implement secondary reaming corrosion, reaming current density is 50 mA / cm 2 , The hole reaming power density is 30C / cm 2 ; After cleaning with pure water, post-treatment is carried out; after cleaning, drying is performed, and the thickness of the aluminum foil is about 80μm. Among them, the neutral salt solution is NaNO with a concentration of 0.5 wt% 3, The trace additives are oxalic acid with a concentration of 0.01 wt% and ZnO with a concentration of 0.01 wt %.

Embodiment 2

[0040] The thickness of the aluminum foil is 90μm. After the aluminum foil is pretreated, it is subjected to primary pore corrosion, and the pore current density is 150 mA / cm 2 , The hole electricity density is 18C / cm 2 ; Rinse with pure water and put it into a neutral salt solution containing additives for intermediate corrosion, the current density is 100 mA / cm 2 , The power density is 12C / cm 2 ; After cleaning with pure water, implement secondary reaming corrosion, reaming current density is 60 mA / cm 2 , The hole reaming power density is 30C / cm 2 ; After cleaning with pure water, post-treatment is carried out; after cleaning, it is dried and awaiting chemical conversion. Among them, the neutral salt solution is NaCl with a concentration of 5.5wt% , The trace additives are a mixture of oxalic acid, citric acid and boric acid with a concentration of 0.1 wt%, and a concentration of 0.05 wt% of In(NO 3 ) 3 .

Embodiment 3

[0042] The thickness of the aluminum foil is 100μm. After the aluminum foil is pretreated, it is subjected to first-level pore corrosion, and the pore current density is 200 mA / cm 2 , The hole electricity density is 22C / cm 2 ; Rinse with pure water and put it into a neutral salt solution containing additives for intermediate corrosion, the current density is 100 mA / cm 2 , The power density is 8C / cm 2 ; After cleaning with pure water, perform secondary reaming corrosion, reaming current density is 45 mA / cm 2 , The hole reaming power density is 30C / cm 2 ; After cleaning with pure water, post-treatment is carried out; after cleaning, drying is performed, and the thickness of the aluminum foil is about 100μm. Among them, the neutral salt solution is KCl with a concentration of 10wt% , The trace additives are tartaric acid and benzoic acid with a concentration of 0.2 wt% and ZnO, PbO and Bi (NO 3 ) 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com