Compound rubber protective belt for bridge, preparation method and application thereof

A technology for compound rubber and bridges, used in bridges, bridge parts, bridge construction, etc., can solve the problems of limited strength of anti-corrosion coating, affecting anti-corrosion effect, high construction technology, etc., to reduce construction procedures, excellent anti-corrosion effect, reduce The effect of construction technology requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

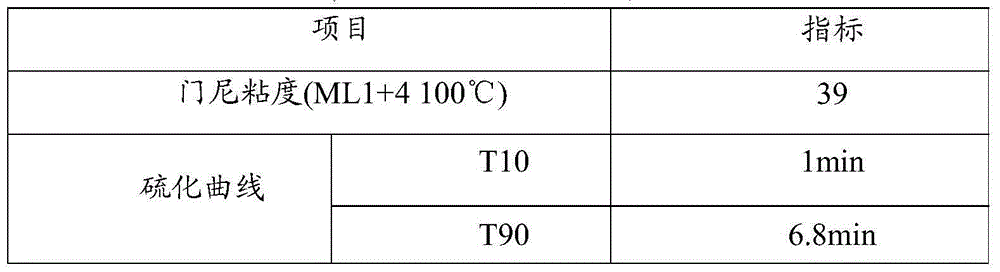

[0074] A composite rubber protective belt for a bridge is formed by calendering chlorosulfonated polyethylene rubber and grid cloth, and the chlorosulfonated polyethylene rubber is prepared from the following raw materials in parts by weight:

[0075]Chlorosulfonated polyethylene: 40 parts;

[0076] White carbon black: 10 parts;

[0077] Heavy calcium carbonate: 25 parts;

[0078] Titanium dioxide: 8 parts;

[0079] Dioctyl phthalate: 10 parts;

[0080] Pentaerythritol: 1.5 parts;

[0081] TRA: 1 copy;

[0082] Pigment: 0.1 part;

[0083] Magnesium oxide: 2.89 parts;

[0084] Carbon black: 0.01 part;

[0085] PE wax: 1.5 parts;

[0086] In this embodiment, the mesh cloth may be nylon mesh cloth, which is treated with acrylic glue dipping before calendering.

[0087] The chlorosulfonated polyethylene rubber of the present embodiment amounts to 100 parts, and the preparation method of this bridge composite rubber protective belt comprises the following steps:

[0088] ...

Embodiment 2

[0094] A composite rubber protective belt for a bridge is formed by calendering chlorosulfonated polyethylene rubber and grid cloth, and the chlorosulfonated polyethylene rubber is prepared from the following raw materials in parts by weight:

[0095] Chlorosulfonated polyethylene: 35 parts;

[0096] White carbon black: 15 parts;

[0097] Heavy calcium carbonate: 20 parts;

[0098] Titanium dioxide: 12 parts;

[0099] Dioctyl phthalate: 12 parts;

[0100] Pentaerythritol: 1 part;

[0101] TRA: 1 copy;

[0102] Pigment: 0.3 parts;

[0103] Magnesium oxide: 2.68 parts;

[0104] Carbon black: 0.02 part;

[0105] PE wax: 1 part;

[0106] The chlorosulfonated polyethylene rubber of the present embodiment amounts to 100 parts, and the preparation method of this bridge composite rubber protective belt comprises the following steps:

[0107] 1) Mastication: Take 35 parts of chlorosulfonated polyethylene, put it into the mixer, and perform plastication at 100°C±5;

[0108] 2)...

Embodiment 3

[0114] A composite rubber protective belt for a bridge is formed by calendering chlorosulfonated polyethylene rubber and grid cloth, and the chlorosulfonated polyethylene rubber is prepared from the following raw materials in parts by weight:

[0115] Chlorosulfonated polyethylene: 45 parts;

[0116] White carbon black: 10 parts;

[0117] Heavy calcium carbonate: 25 parts;

[0118] Titanium dioxide: 6 parts;

[0119] Dioctyl phthalate: 10 parts;

[0120] Pentaerythritol: 0.5 parts;

[0121] TRA: 0.5 parts;

[0122] Pigment: 0.2 parts;

[0123] Magnesium oxide: 1.78 parts;

[0124] Carbon black: 0.02 parts;

[0125] PE wax: 1 part;

[0126] The chlorosulfonated polyethylene rubber of the present embodiment amounts to 100 parts, and the preparation method of this bridge composite rubber protective belt comprises the following steps:

[0127] 1) Mastication: Take 45 parts of chlorosulfonated polyethylene, put it into the mixer, and perform plastication at 100°C±5;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com