Preparation method of 3-site substituted benzoyl-beta-cyclodextrin

A technology of benzoyl and cyclodextrin, which is applied in the field of preparation of benzoyl-β-cyclodextrin, can solve the problems of many by-products and low yield, and achieve the effect of strong operability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

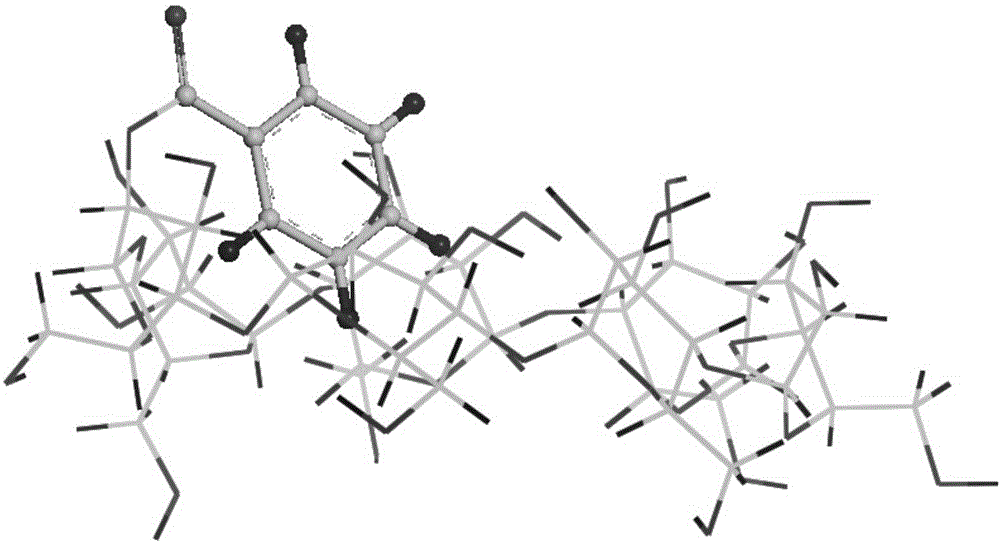

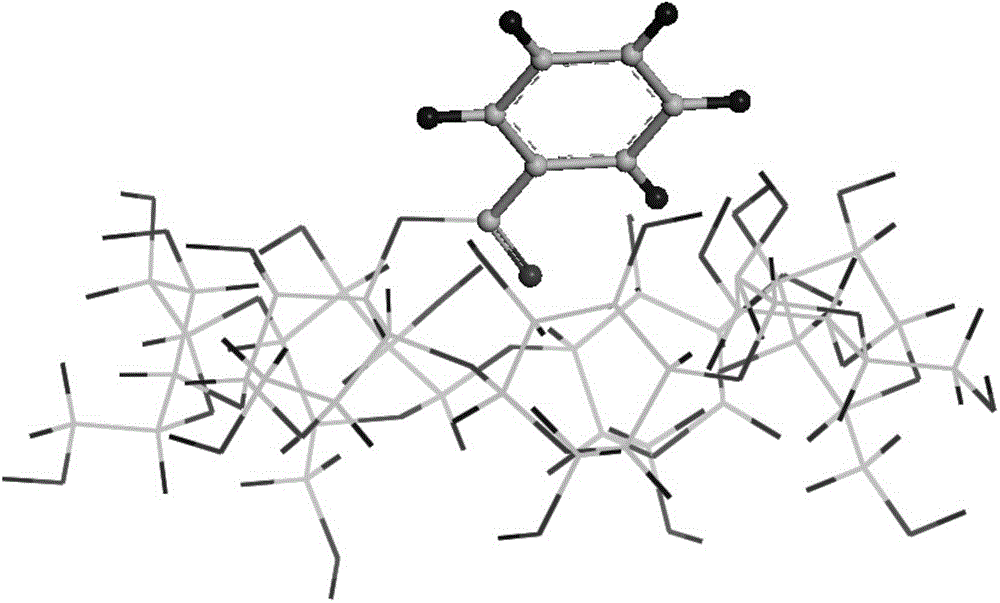

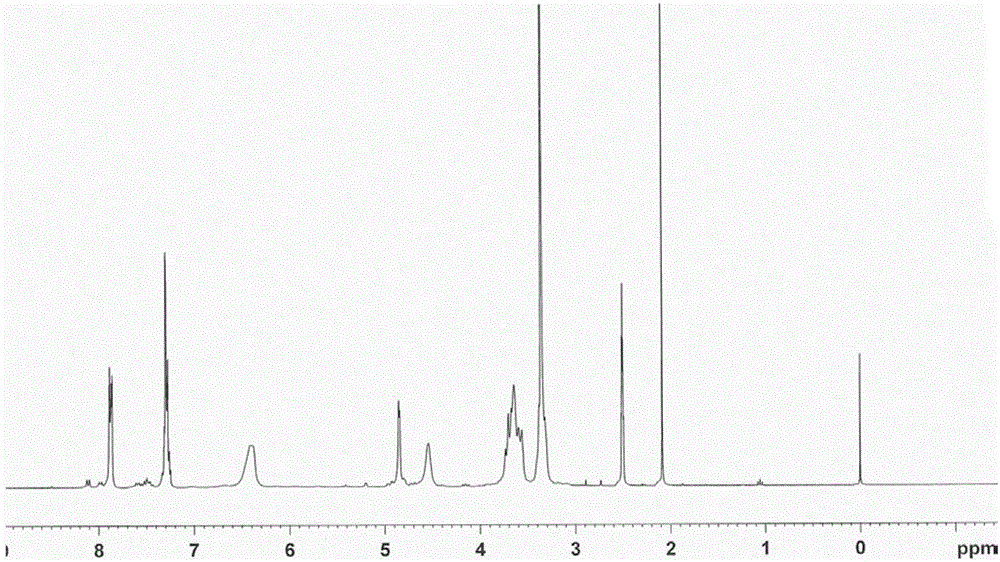

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of 3-substituted benzoyl-β-cyclodextrin, comprising steps as follows:

[0046] (1) Dissolve 6.63g (48mmol) of potassium carbonate and 6.81g (6.0mmol) of β-cyclodextrin in a mixed solvent consisting of 40mL of purified water and 15mL of N,N-dimethylformamide (DMF). solution;

[0047](2) Dissolve 6.75g (48mmol) of benzoyl chloride in 25mL of N,N-dimethylformamide (DMF), and add it dropwise to the mixed solution obtained in step (1) within 1h at 20°C, Add 3mol / L potassium hydroxide solution during the dropwise addition to maintain the pH of the solution between 9 and 11;

[0048] (3) After the dropwise addition is completed, neutralize the solution obtained in step (2) with 2mol / L hydrochloric acid to neutrality;

[0049] (4) Distill under reduced pressure at 75mmHg and 60°C, evaporate the solution obtained in step (3) to dryness, and vacuum-dry at 40°C for 6 hours to obtain a crude product;

[0050] (5) Add 10 g of the crude product obtained in ste...

Embodiment 2

[0062] A preparation method of 3-substituted benzoyl-β-cyclodextrin, comprising steps as follows:

[0063] (1) Dissolve 1g of potassium carbonate and 10g of β-cyclodextrin in a mixed solvent consisting of 20mL of N,N-dimethylformamide (DMF) and 50mL of purified water to obtain a mixed solution;

[0064] (2) Dissolve 10g of benzoyl chloride in 25mL of N,N-dimethylformamide (DMF), and add it dropwise to the mixed solution obtained in step (1) within 5 hours at 10°C. 3mol / L potassium hydroxide solution to maintain the pH of the solution between 9 and 11;

[0065] (3) After the dropwise addition is completed, neutralize the solution obtained in step (2) with 2mol / L hydrochloric acid to neutrality;

[0066] (4) Distill under reduced pressure at 75mmHg and 60°C, evaporate the solution obtained in step (3) to dryness, and vacuum-dry at 60°C for 4 hours to obtain a crude product;

[0067] (5) Add 15 g of the crude product obtained in step (4) into 50 mL of N,N-dimethylformamide (DMF...

Embodiment 3

[0071] A preparation method of 3-substituted benzoyl-β-cyclodextrin, comprising steps as follows:

[0072] (1) Dissolve 10 g of potassium carbonate and 1 g of β-cyclodextrin in a mixed solvent consisting of 20 mL of N,N-dimethylformamide (DMF) and 50 mL of purified water to obtain a mixed solution;

[0073] (2) Dissolve 10g of benzoyl chloride in 25mL of N,N-dimethylformamide (DMF), and add it dropwise to the mixed solution obtained in step (1) within 1 hour at 80°C. 3mol / L potassium hydroxide solution to maintain the pH of the solution between 9 and 11;

[0074] (3) After the dropwise addition is completed, neutralize the solution obtained in step (2) with 2mol / L hydrochloric acid to neutrality;

[0075] (4) Distill under reduced pressure at 75mmHg and 60°C, evaporate the solution obtained in step (3) to dryness, and vacuum-dry at 20°C for 6 hours to obtain a crude product;

[0076] (5) Add 6 g of the crude product obtained in step (4) into 50 mL of N,N-dimethylformamide (D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com