Wall-climbing robot for magnetic particle defect testing

A wall-climbing robot and magnetic particle flaw detection technology, applied in the field of wall-climbing robots, can solve problems such as high risk, low efficiency, and cumbersome magnetic flaw detection work, and achieve the effects of prolonging service life, reducing resistance, and improving unit magnetic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

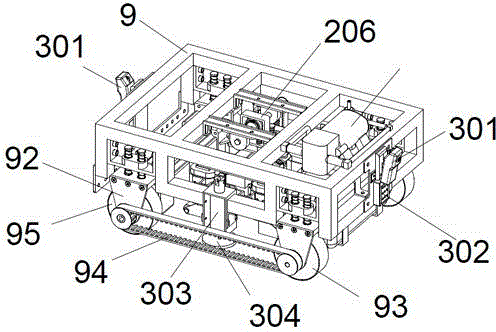

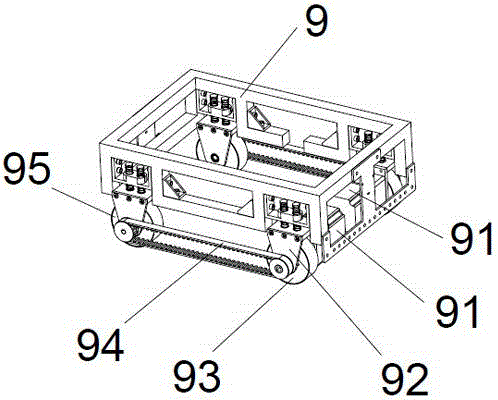

[0055] With reference to the attached drawings, a wall-climbing robot for magnetic particle inspection, including a mobile device, a magnetizing device, a magnetizing device, and a marking device;

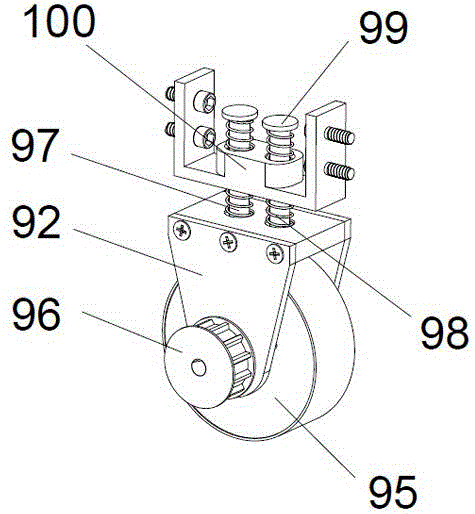

[0056] The mobile device includes a frame 9. Two sets of magnetic adsorption wheels are installed on the frame. Each set of magnetic adsorption wheels is divided into a driving wheel 93 and a driven wheel 95. The driving wheel and the driven wheel are connected by a timing belt 94, and the driving wheel is connected to the driving motor. The shaft 5 of the magnetic adsorption wheel is mounted on the hub 92, the shock-absorbing beam plate 100 is threadedly connected to the frame, and two vertical through holes are opened on the shock-absorbing beam plate for the two shock absorption of the magnetic adsorption wheel The support spring shafts 97 respectively pass through two vertical through holes on the damping beam plate; the top of the spring shaft is provided with a baffle, and spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com