Semicircular thin-wall workpiece processing tool and use method thereof

A thin-walled, semicircular technology, used in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve problems such as the inability to process the outer circumference of the workpiece, achieve small deformation, overcome workpiece deformation, and reduce deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this example, the processing material is ZCuAl9Mn2, the outer diameter is Φ295 (+0.04 / +0.015), the inner diameter is Φ280 (+0.18 / +0.15), the total length of the workpiece is 310 (0 / -0.1), and the ratio of outer diameter to thickness is 295 / 7.5= 39.3, the coaxiality is 0.05, and the gap between the two semi-circular workpieces is less than 0.05 as an example.

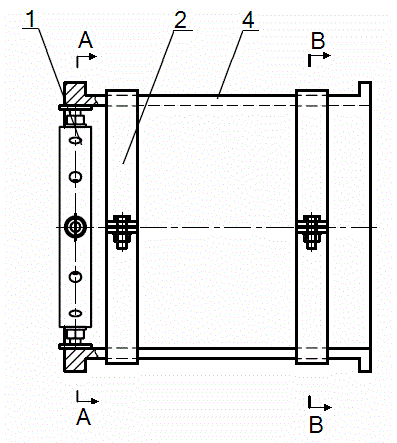

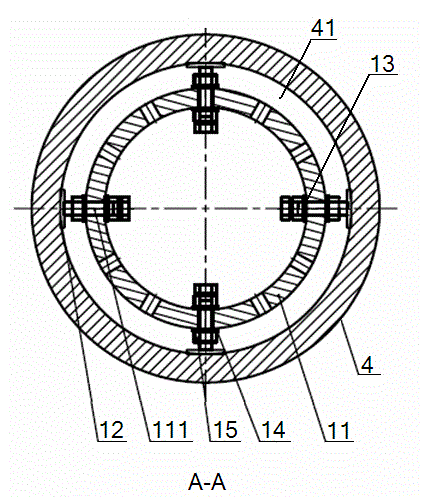

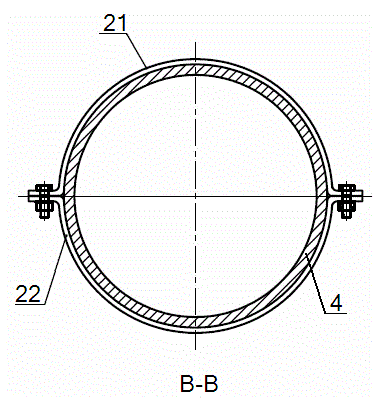

[0063] see figure 1 - Image 6 , a semicircular thin-walled part processing tooling, including inner hole tooling 1, Haval clamp tooling 2, milling tooling 3, said inner hole tooling 1 includes inner hole tooling body 11, compression block 12, compression screw 13, Tooling gasket 14, stop nut 15, the inner hole tooling body 11 is evenly provided with a plurality of tooling holes 111 along its circumference, and the compression screw 13 passes through the inner wall of the compression block 12 and the workpiece 4 after passing through the tooling hole 111 Compression fit, and fixed on the inner hole tooling bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com