A Turbine Guide Vane Automatic Spraying Support Protection Fixture

A turbine guide vane and automatic spraying technology, applied in the direction of spraying devices, etc., can solve the problems of inability to guarantee the consistency of blade coating quality and unstable process parameters, etc., and achieve the goals of reducing equipment working time, strong flexibility, and saving time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The process fixture described in the present invention is a special tool, so only the installation implementation of this type of guide vane is listed below.

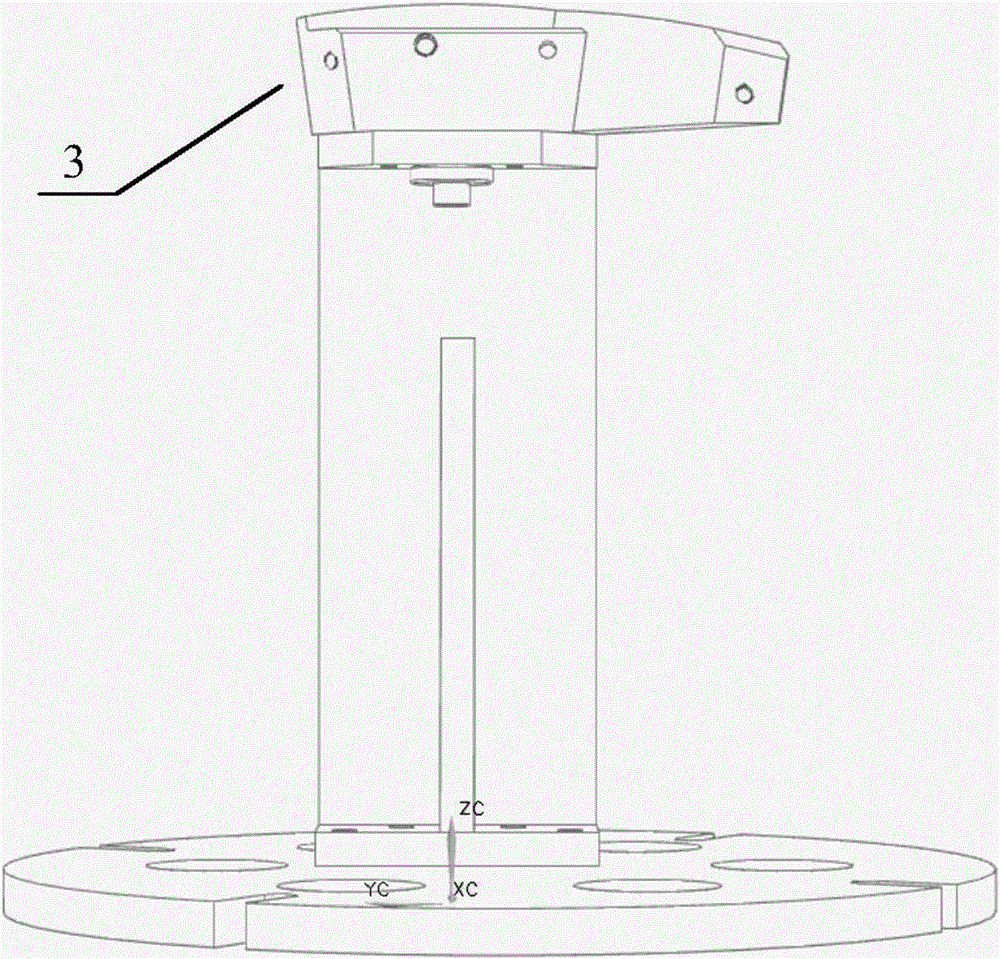

[0023] A turbine guide vane automatic spraying support and protection fixture, characterized in that it includes a base 1, a support plate 2, a positioning block 3, a lower baffle 4, an upper baffle 5,

[0024] The base 1 is disc-shaped, with cross grooves arranged in the circumferential direction, fixed to the center of the turntable with bolts,

[0025] The support plate 2 is installed vertically on the base 1, and the top of the support plate 2 is a plane;

[0026] The positioning block 3 is a V-shaped plate structure with an opening forward to install the guide vane. The bottom surface of the positioning block 3 is installed on the top plane of the support plate 2 through bolts. The shape of the installation edge matches, and the upper edge of the positioning block 3 is flush with the height of the sprayed e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com