Feeding cutting device and orderly vegetable harvesting machine with same

A cutting device and harvester technology, which is applied in the field of agricultural and forestry machinery, can solve the problems of being easily stuck by sand and soil, not being convenient enough, and unable to ensure orderly transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

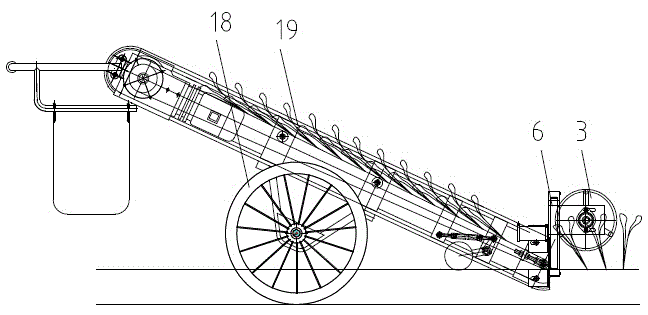

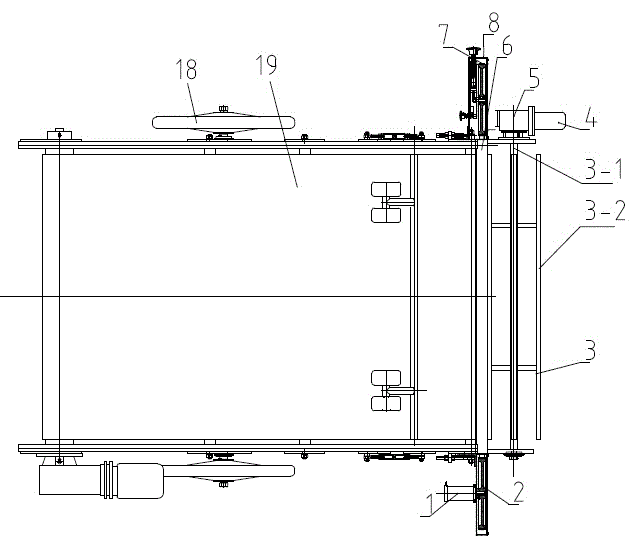

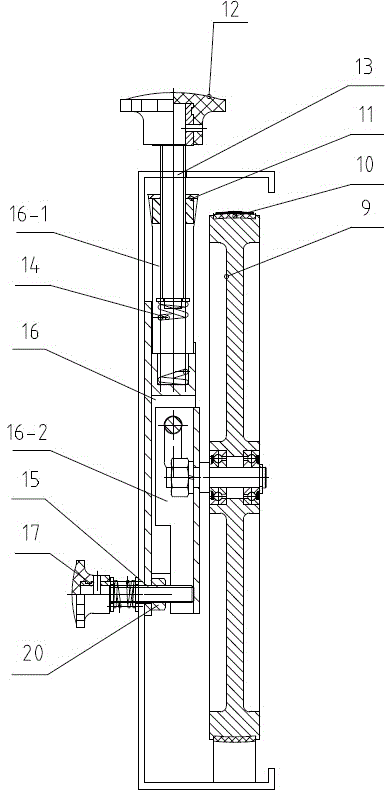

[0019] The feeding and cutting device of the present embodiment and the orderly vegetable harvester with the device are as figure 1 , figure 2 and image 3 As shown, the upper line of the two horizontal lines in the figure indicates the plane of the vegetable ridge, and the lower line indicates the plane of the vegetable ditch. The orderly harvester for vegetables includes a loop belt conveyer 19 which is arranged on the walking wheels 18 and is low in the front and high in the rear. The front end of conveying device 19 is equipped with the vegetable cutting mechanism 6 that stretches forward. The vegetable cutting mechanism 6 includes a frame-shaped transmission frame 8 substantially perpendicular to the forward direction, and the left and right ends of the transmission frame 8 respectively support the driving wheel 2 and the driven wheel 9 surrounding the endless belt knife 7 . The cutting motor 1 drives the driving wheel 2 . The middle part of the outer circle of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com