Rotating liquid variable resistor, rotating liquid variable resistor cluster and motor starter

A resistor and variable technology, applied in the direction of liquid resistor, motor generator/starter, starter of a single multi-phase induction motor, etc., can solve the problems of complex mechanical structure, easy damage, etc., and achieve low cost and high cost. Low, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Implementation example 1, such as figure 1 As shown, a rotating liquid variable resistor is mainly composed of a cavity 100, a conductive liquid 101, a resistor body 102, an electrode 103, and an electrode 1031;

[0059] The cavity 100 has a symmetry axis 109; the conductive liquid 101 is loaded in the cavity 200;

[0060] The volume of the conductive liquid 101 is smaller than the effective volume of the cavity 100;

[0061] The resistor body 102 is arranged in the cavity 100; the surface of the resistor body 102 has a continuous span in the axial direction of the rotation axis of the cavity 100; the lower end of the resistor body 102 is in contact with the conductive liquid 101; the upper and lower ends of the resistor body 102 are respectively connected to the The electrodes 103 and 1031 are electrically connected; the electrodes 103 and 1031 penetrate the interface of the cavity 100 and intervene inside the cavity 100;

[0062] The electrode 103 is connected to th...

Embodiment 2

[0064] Implementation example 2, such as figure 2 As shown, a rotating liquid variable resistor is mainly composed of a cavity 200, a conductive liquid 201, a resistor body 202, an electrode 203, and an electrode 2031;

[0065] The cavity 200 has an axis of symmetry 209;

[0066] The conductive liquid 201 is loaded in the cavity 200;

[0067] The volume of the conductive liquid 201 is smaller than the effective volume of the cavity 200;

[0068] The resistor body 202 is arranged at the axial position in the cavity 200;

[0069] The surface of the resistor body 202 has a continuous span in the axial direction of the rotation axis of the cavity 200;

[0070] The lower end of the resistor body 202 is in contact with the conductive liquid 201;

[0071] The upper end and the lower end of the resistor body 202 are electrically connected to the electrodes 203 and 2031 respectively;

[0072] The electrodes 203 and 2031 penetrate the interface of the cavity 200 and intervene insi...

Embodiment 3

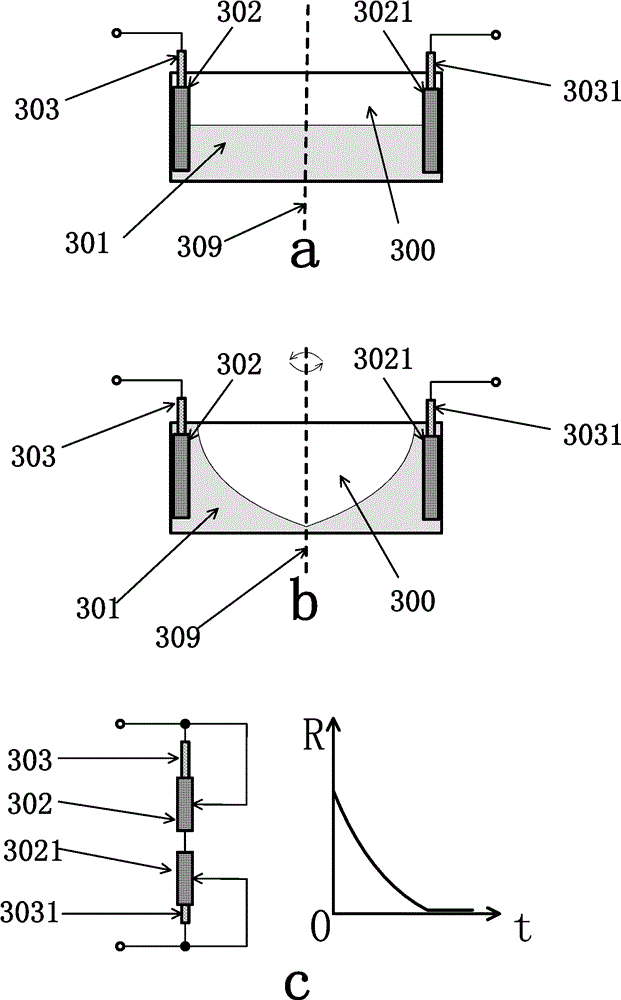

[0075] Implementation example 3, such as image 3 As shown, a rotating liquid variable resistor is mainly composed of a cavity 300, a conductive liquid 301, a resistor body 302, a resistor body 3021, an electrode 303, and an electrode 3031;

[0076] The cavity 300 has an axis of symmetry 309;

[0077] The conductive liquid 301 is loaded in the cavity 300;

[0078] The volume of the conductive liquid 301 is smaller than the effective volume of the cavity 300;

[0079] The resistors 302 and 3021 are arranged at the inner and outer edges of the cavity 300;

[0080] The surfaces of the resistors 302, 3021 have a continuous span in the axial direction of the rotation axis of the cavity 300;

[0081] The lower ends of the resistors 302, 3021 are in contact with the conductive liquid 301;

[0082] The upper end of the resistor 302 is electrically connected to the electrode 303, and the lower end of the resistor 3021 is electrically connected to the electrode 3031;

[0083] The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com