Ferrograph for ships and measurement and analysis method

A measuring method and ferrograph technology, which are applied in the field of measuring instruments to achieve the effects of simple structure and improved repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The marine ferrography instrument and its measurement and analysis method of the present invention will be described in detail below in conjunction with specific embodiments.

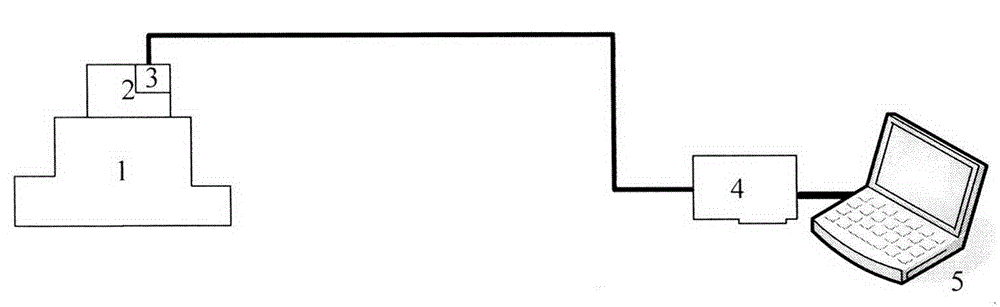

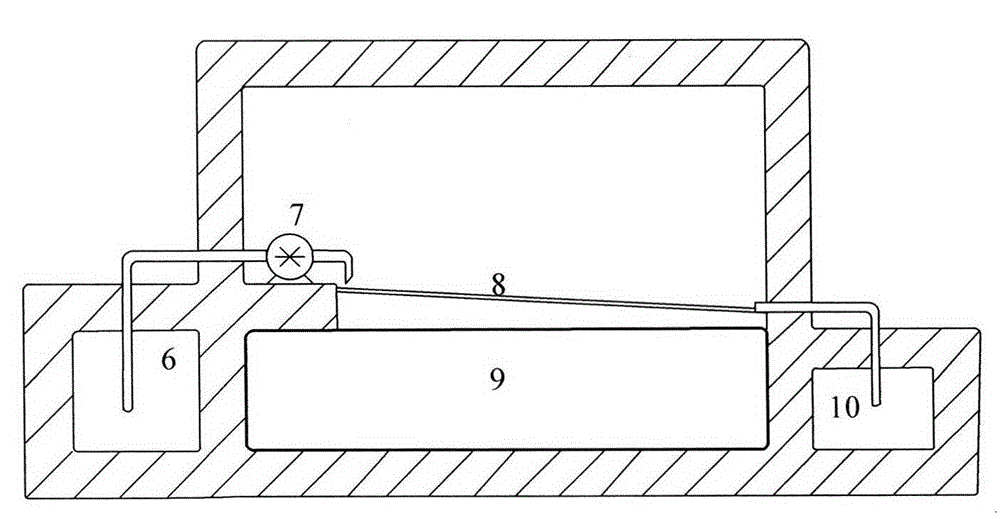

[0016] 1. The structure and specific working process of the marine ferrgraph

[0017] The composition of the marine ferrography instrument includes: spectrometry device 1, high-pixel camera 2, USB3, virtual instrument device 4, and notebook computer 5. The lubricating oil in the oil sample pool 6 in the spectrum making device 1 leaves abrasive grains on the glass substrate 8 through the micro pump 7, and the lubricating oil enters the waste oil pool 9. The high-pixel camera 2 takes high-definition images of the abrasive grains, and transmits the high-definition images to the notebook computer 5 through the virtual instrument device 4 . The image preprocessing software in the notebook computer 5 preprocesses the image to obtain five parameters including the area of abrasive grains in the image,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com