A material guide device and a dryer

A material guiding device and material guiding technology, applied in drying, drying solid materials, lighting and heating equipment, etc., can solve the problems of too high temperature of the material guiding device, melting of fertilizer particles, etc., so as to avoid melting and bonding and directly absorb , good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

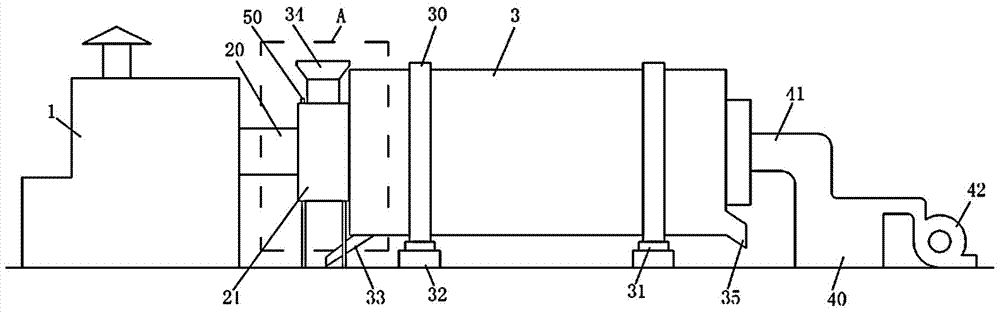

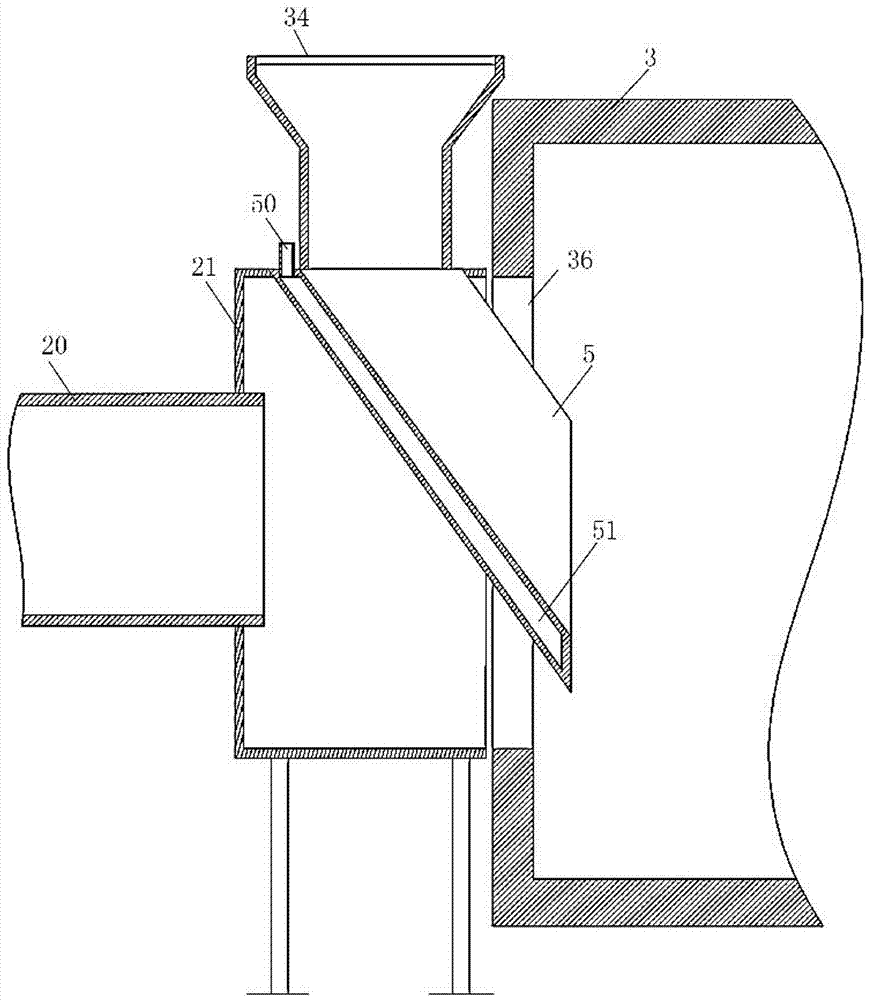

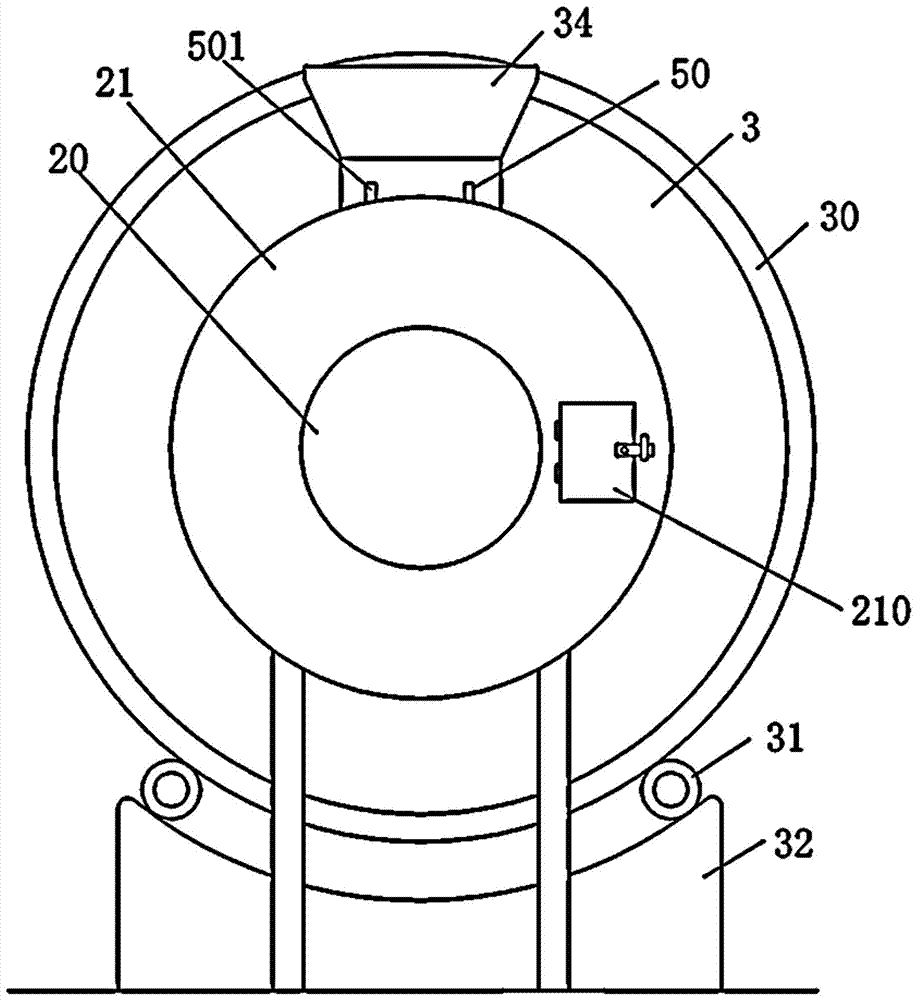

[0022] The dryer of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0023] Embodiment one of the drying machine of the present invention: as Figure 1-5 As shown, including cylinder 3, the front end of cylinder 3 is provided with sealing blanking device 21, and sealing blanking device 21 is cylindrical structure, and the front end of sealing blanking device 21 is provided with air inlet, and air inlet passes air inlet pipe 20 Connected to the air outlet of the boiler 1, the rear end of the sealing and blanking device 21 is an open structure, and is aligned with the front opening of the cylinder 3, the hot air in the boiler 1 enters the sealing and blanking device 21 through the air inlet pipe 20 and passes through the sealing and lowering device 21. The rear end opening of the material device 21 enters the inside of the cylinder body 3, the rear end of the sealing material feeding device is spaced apart from the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com