Hollow buffer drive

A buffer-driven, hollow technology, applied in the direction of fluid pressure actuators, injection devices, pipe supports, etc., can solve the problems of exposure to the external environment and complex overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

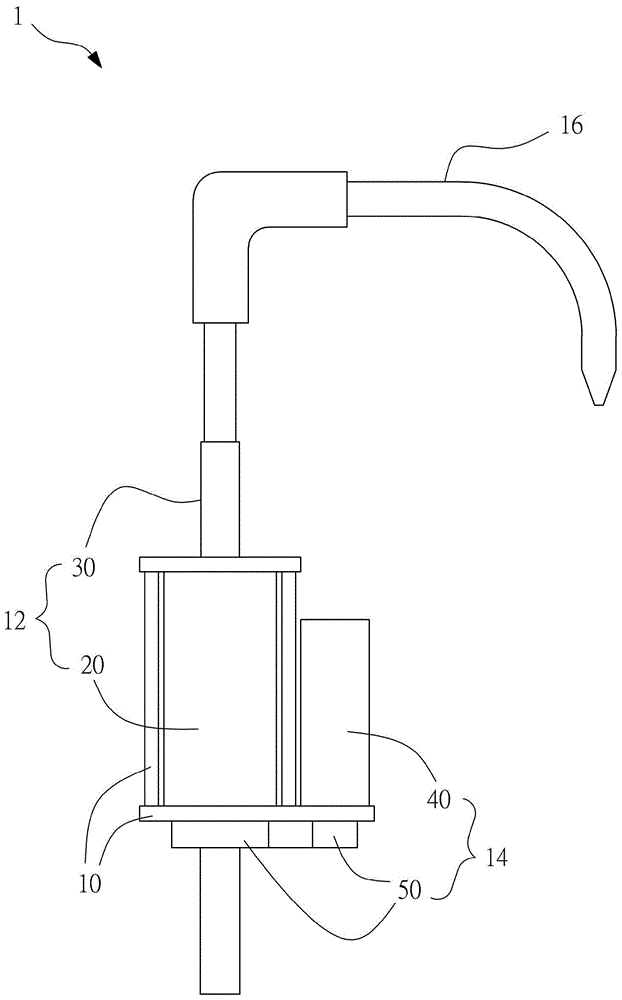

[0071] Please refer to figure 1 , which shows a perspective view of a hollow buffer driving device 1 according to an embodiment of the present invention. The hollow buffer driving device 1 includes a base 10 , a lift mechanism unit 12 , a rotation mechanism unit 14 , and a pipeline support unit 16 . Wherein, the lifting mechanism unit 12 is rotatably mounted on the base 10 ; the rotating mechanism unit 14 is mounted on the base 10 for rotating the lifting mechanism unit 12 ; the pipeline support unit 16 is mounted on the lifting mechanism unit 12 .

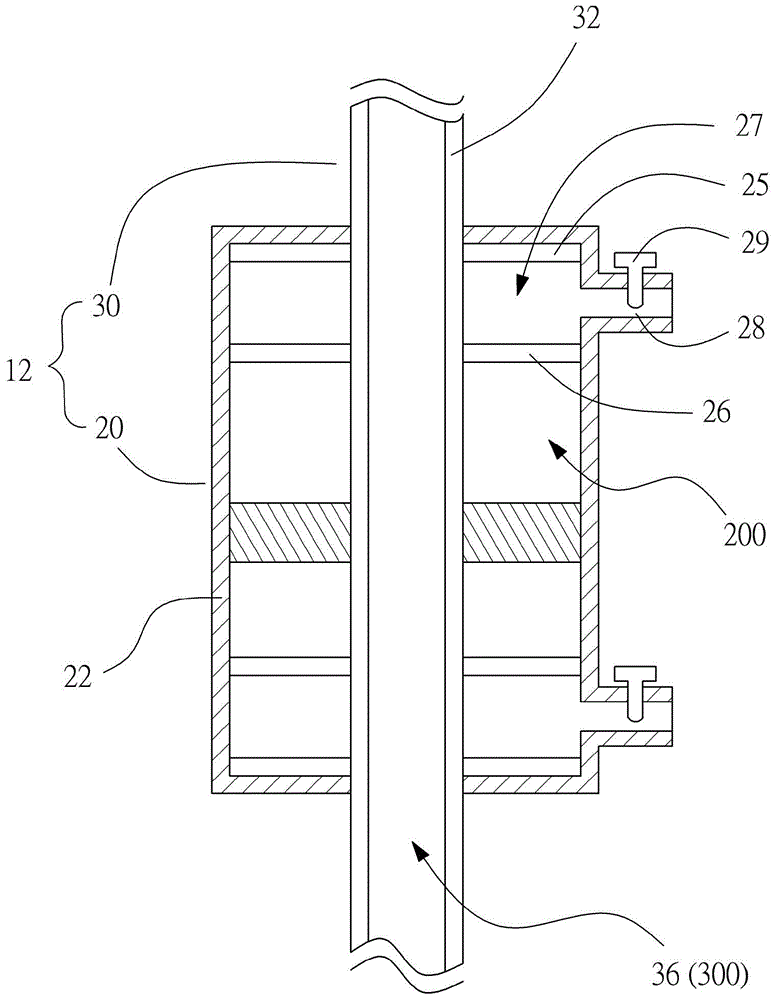

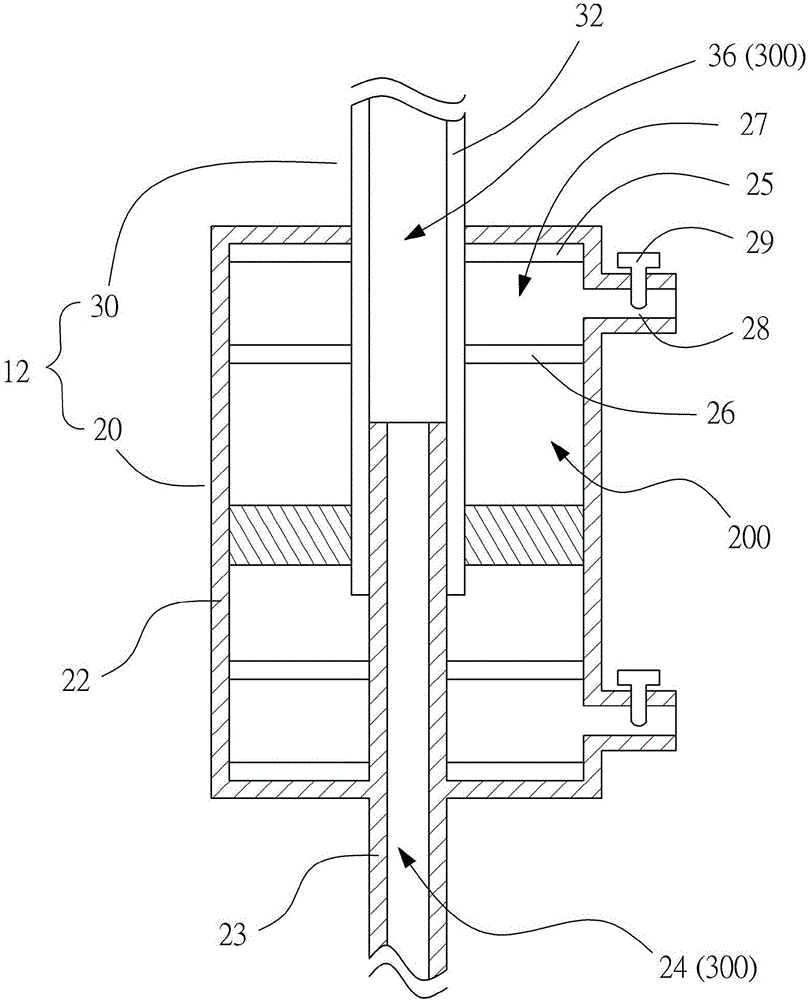

[0072] Please refer to Figure 2A , which shows a cross-sectional view of the lifting mechanism unit 12 according to an embodiment of the present invention. The lifting mechanism unit 12 has a cylinder body 20 and a piston rod 30; the cylinder body 20 has a housing 22, and the housing 22 defines a cylinder body space 200; the piston rod 30 has a handle 32, and the handle 32 is hollow to A handle space 36 is defined and passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com