Bevel gear drive device

A technology of bevel gear transmission and bevel gear, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of bevel gear tooth surface contact fatigue, noise, and influence on transmission stability, so as to achieve less fatigue and lower noise , the effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

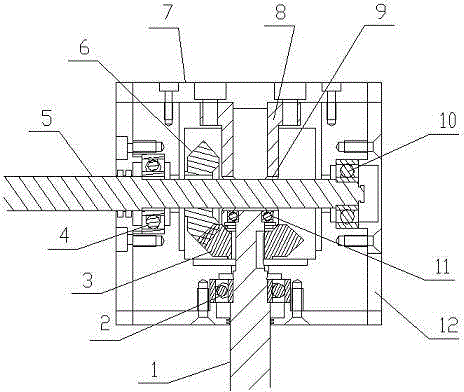

[0020] Referring to accompanying drawing 1, the first embodiment of the present invention is a bevel gear transmission in which the power output shaft is perpendicular to the power input shaft, which includes a square frame composed of four frames 12, a power input shaft 1, a bearing 2. Drive bevel gear 3, bushing 8, middle support bearing 11, power output shaft 5, driven bevel gear 6, bearing 4, bearing 10 installed on power output shaft 5 installed on power input shaft 1. Sleeve 8 is a metal rigid rotary part, the central axis of sleeve 8 and the central axis of power input shaft 1 are on the same straight line, and there is a through hole 9 with a diameter larger than the outer diameter of power output shaft 5 on the sleeve 8. One end of the casing 8 is fixedly installed on the support seat 7 on the frame, and the other end of the casing 8 is installed with a middle support bearing 11, the outer ring of the middle support bearing 11 is fixedly connected with the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com