Flame-retardant insulation fabric with anti-fouling function

A flame retardant thermal insulation and fabric technology, applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of flame retardant fabrics slowly disappearing, uncomfortable to wear, easy to get dirty, etc., to achieve no irritating odor, fabrics Soft and comfortable, smoothness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

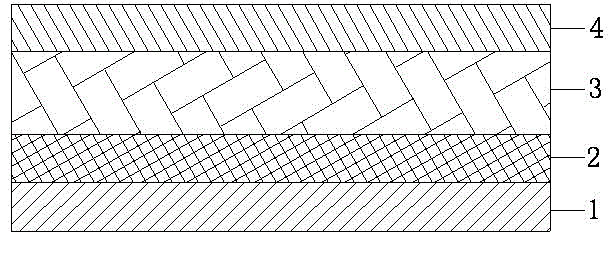

[0015] see figure 1 , the present invention relates to a kind of flame retardant thermal insulation fabric with antifouling function, it comprises fabric body 1, the upper surface of described fabric body 1 is covered with thermal insulation layer 2, and thermal insulation layer 2 can play the role of thermal insulation, and the thermal insulation layer 2 Covered with a waterproof layer 3, the waterproof layer 3 can ensure the drying of the thermal insulation layer 4, and the surface of the waterproof layer 3 is covered with a layer of polyurethane coating layer 4, and the polyurethane coating layer 4 is a fluorine monomer water-based polyurethane, which can improve the quality of the fabric. The smoothness makes the fabric not easy to stain, and it is waterproof and breathable.

[0016] The fabric body is made of fabric, and the fabric is formed by interweaving warp yarns and weft yarns, the warp yarns are made of cotton yarns, and the weft yarns are made of flame-retardant p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com