Application of Dextrin Molecular Weight Characteristics in Detecting Starch Liquefaction Effect

A starch liquefaction and molecular weight technology, applied in the field of starch deep processing, can solve the problems of high volatility, inability to truly reflect the sugar composition and molecular weight distribution of dextrin mixtures, and low accuracy, and achieve rational control, fine control, and improvement. effect of industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment, the present invention is described in detail.

[0020] Weigh 40g of cornstarch into a beaker; add 200mL of deionized water (room temperature) and mix well, adjust the pH to 5.8-6.0 with 0.1mol / L NaOH; add 1200U of high-temperature α-amylase, and stir well. Place in a 99°C super constant temperature water bath (equipped with a magnetic stirring device), stir evenly, and the iodine test is light brown and qualified; immediately adjust the pH to 3.0 with 0.1mol / L HCI, inactivate the enzyme to terminate the reaction, and after equilibrating for 5 minutes, use 0.1mol / L NaOH to neutralize and adjust the pH to neutral. Dilute the starch hydrolyzate to prepare a dextrin solution with a mass concentration of 7% (w / w).

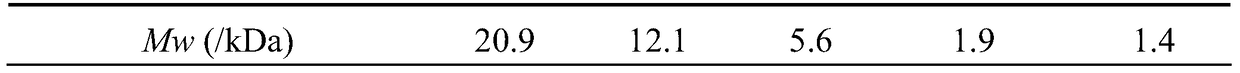

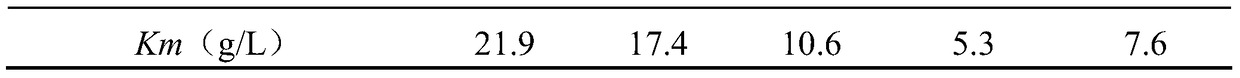

[0021] Take 100mL of dextrin solution, slowly add ethanol, and keep stirring until the final concentration of ethanol is 30% (v / v), put it in a refrigerator at 4°C for 24h, centrifuge (4°C, 10000g, 20min), and precipitate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com