Preparation method of porous aromatic framework compound constructed with benzene ring base blocks

A technology for porous aromatic skeletons and compounds, which is applied in the field of preparation of porous aromatic skeleton compounds constructed from benzene ring blocks, which can solve the problems of high price of reaction catalysts, complex and harsh reaction conditions, and low reaction yields, and achieve simple reaction methods Ease of operation, high application value and market value, and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

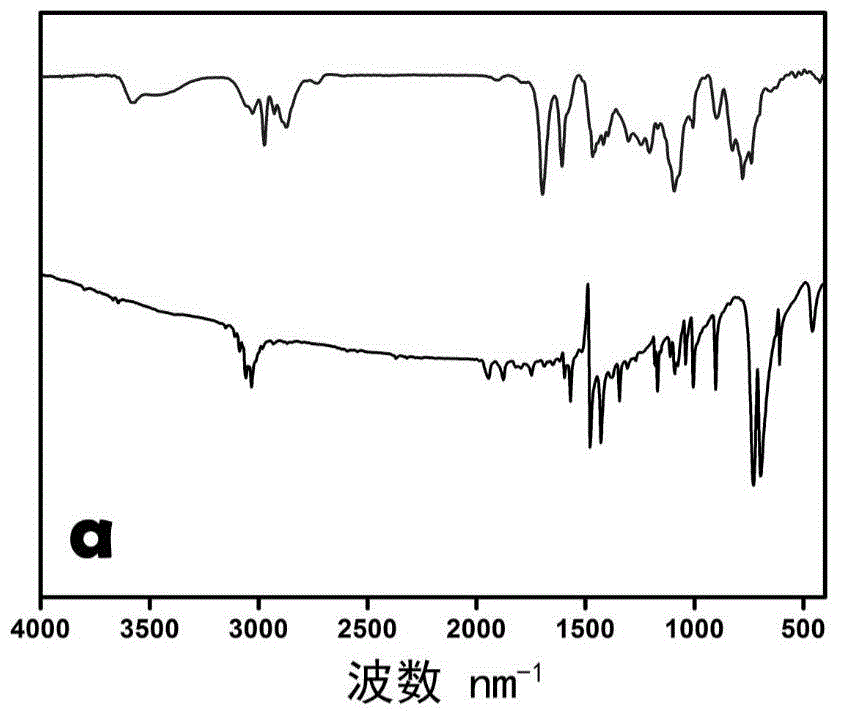

[0045] Specific embodiment one: the preparation method of polybiphenyl is as follows:

[0046] (1) Weighing: feed biphenyl (molecular weight 154.21) and aluminum trichloride (molecular weight 133.34) according to the mass ratio of 1:1, that is, the analytical balance accurately weighs 500 mg (3.750 mmol) of aluminum trichloride and After the biphenyl of 500mg (3.242mmol) (the ratio of the amount of substance of reactant and catalyst is 0.865:1 at this moment), put in the 250mL round-bottomed flask that has dried in advance, and described round-bottomed flask has very strong Sealing, can carry out anhydrous and oxygen-free operation;

[0047](2) Dissolution and reaction of the reactant: Accurately inject 100 mL of anhydrous chloroform (the concentration of the reactant biphenyl is 0.03242 mol / L) after dry pretreatment in the round bottom flask with a syringe, and then put A magnetic stirrer with a size of 1 cm was inserted to replace the gas in the round bottom flask, so that ...

specific Embodiment 2

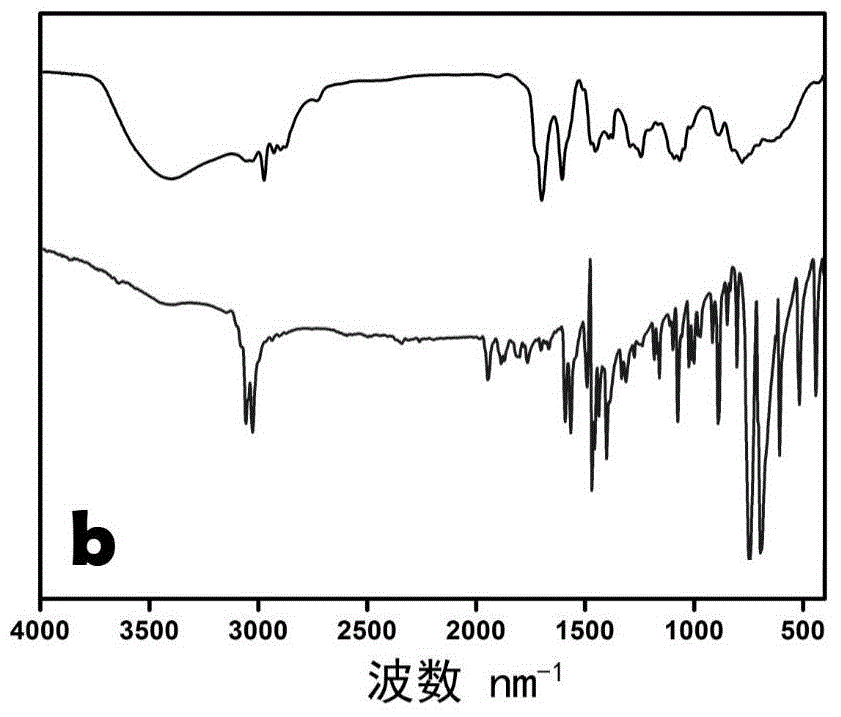

[0052] Specific embodiment two: the preparation method of polym-terphenyl is as follows:

[0053] (1) Weighing: Feed m-terphenyl (molecular weight 230.30) and aluminum trichloride (molecular weight 133.34) in a mass ratio of 1:1, that is, accurately weigh 500 mg (3.750 mmol) of aluminum trichloride with an analytical balance and 500mg (2.171mmol) of m-terphenyl (at this time, the ratio of the amount of reactant and catalyst is 0.579), put it into the pre-dried 250mL round bottom flask, and the round bottom flask has a strong Sealing, can carry out anhydrous and oxygen-free operation;

[0054] (2) Dissolving and reacting of reactant: Accurately inject 100mL anhydrous chloroform (the amount concentration of reactant m-terphenyl) after dry pretreatment in the round-bottom flask with a syringe, and then A magnetic stirring bar with a size of 1 cm was put in to replace the gas in the round bottom flask, so that the internal reaction was carried out under the protection of nitrogen...

specific Embodiment 3

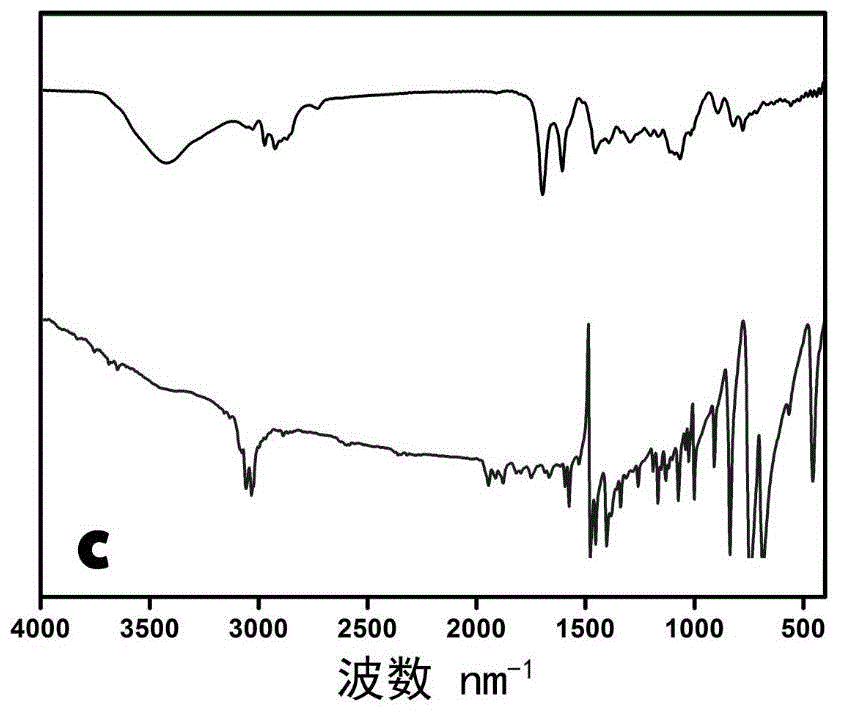

[0059] Specific embodiment three: the preparation method of poly-p-terphenyl is as follows:

[0060] (1) Weighing: Feed p-terphenyl (molecular weight 230.30) and aluminum trichloride (molecular weight 133.34) in a mass ratio of 2:1, that is, the analytical balance accurately weighs 1.000g (7.500mmol) of trichloride After aluminum and 2.000g (8.684mmol) p-terphenyl (the ratio of the amount of substance of reactant and catalyst is 1.158:1), put it into the pre-dried 250mL round-bottomed flask, the round-bottomed flask It has strong sealing performance and can be operated without water and oxygen;

[0061] (2) Dissolving and reaction of reactant: Accurately inject 100mL anhydrous trichloromethane (the amount concentration of reactant p-terphenyl) after dry pretreatment in the round-bottomed flask, then A magnetic stirring bar with a size of 1 cm was put in to replace the gas in the round bottom flask, so that the internal reaction was carried out under the protection of nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com