A photoelectric self-induction alarm type wire take-up machine

A wire take-up and alarm technology, which is applied in the field of wire take-up, can solve the problems of lack of automatic alarm prompting device, low automation of wire winding, tearing or separation of wrapped copper layer, etc., and achieves good practical effect, compact structure, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

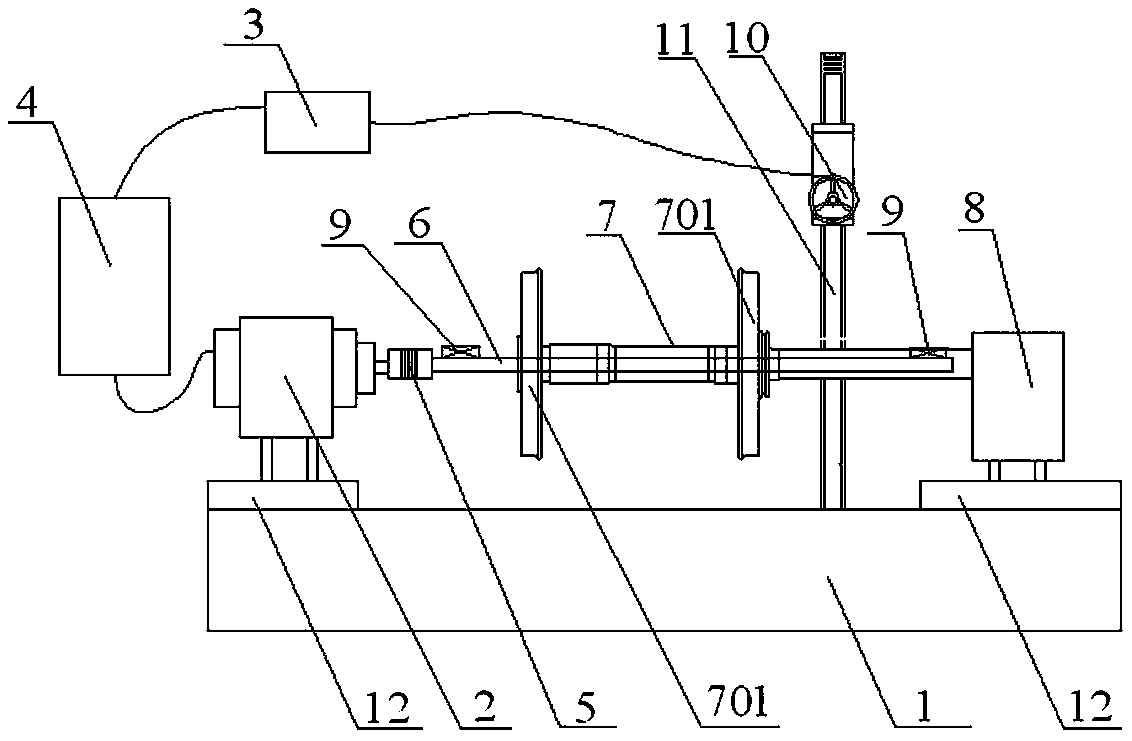

[0017] A photoelectric self-inductance alarm type wire take-up machine, comprising a frame 1, a drive motor 2 arranged on the frame 1, an audible and visual alarm 3 and a PLC control system 4, the output shaft of the drive motor 2 passes through a reducer 5 The deceleration gear is connected to the take-up shaft 6 in transmission, and the take-up shaft 6 is provided with an I-shaped wheel 7 for winding tinned wires. The frame 1 is also provided with a traction device 8, and the drive motor 2 and the traction The devices 8 are all fixed on the frame 1 through a damping plate 12, and the traction device 8 is connected with a disk 701 sleeved on the end of the take-up shaft 6 traction sleeve and the end of the I-shaped wheel 7. The traction sleeve is connected to the I-shaped wheel. One end connected to the disc 701 of the wheel 7 is in the shape of a truncated cone, and the front end of the truncated cone is also provided with a gripping friction ring to prevent slippage between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com