Automatic clamping tool

An automatic clamping and tooling technology, applied in the mechanical field, can solve the problems of difficult quantification of clamping force, excessive clamping force, abnormal processing, etc., to improve efficiency and safety, and ensure the effect of clamping stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

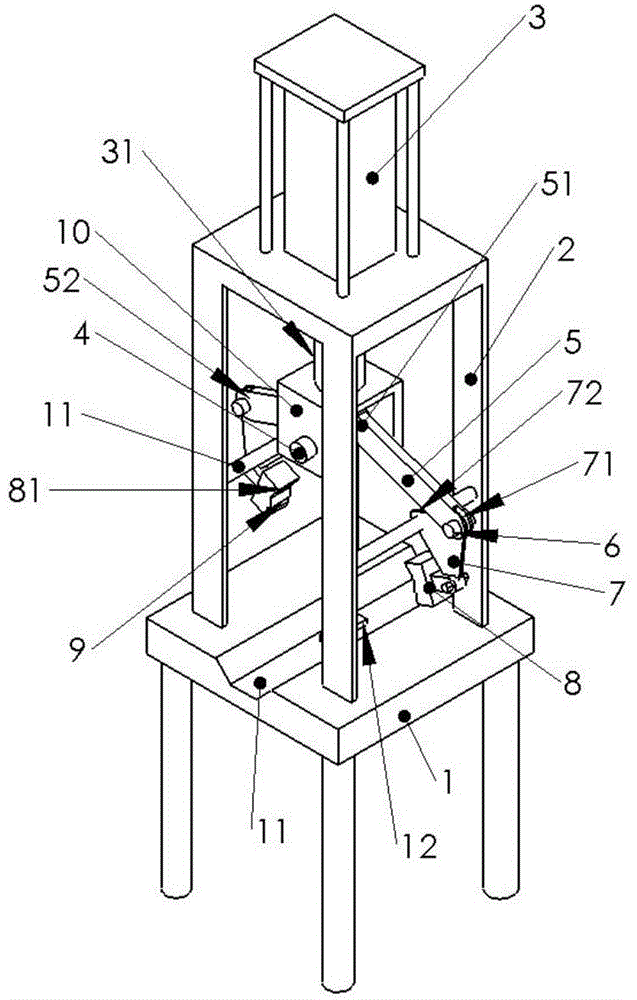

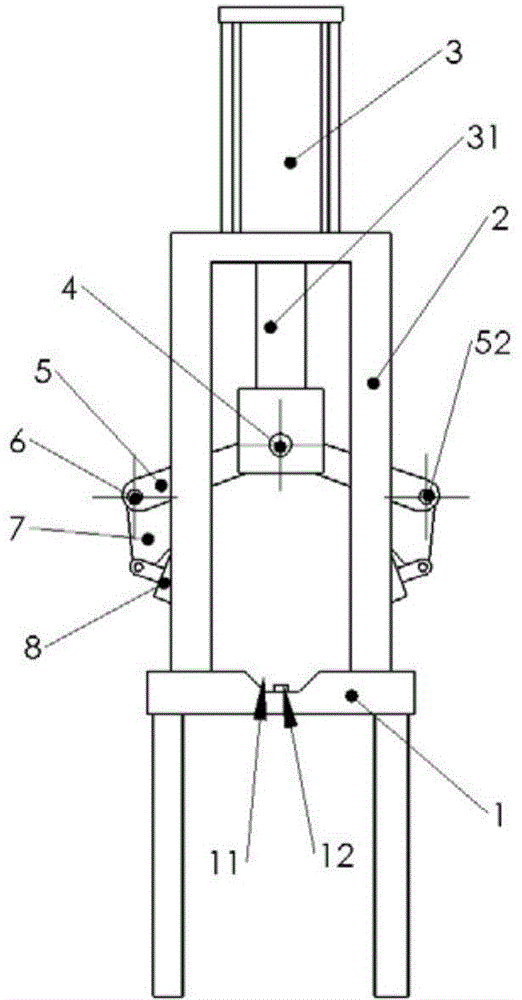

[0021] Such as figure 1 , 2 As shown, an automatic clamping tool, including:

[0022] A workbench 1, the middle part of the workbench 1 is provided with a trapezoidal cross section and a receiving tank 101 horizontally passing through the workbench 1, and a first pressure sensor is arranged in the receiving tank 101, and the first pressure sensor and Controller electrical connection;

[0023] Cylinder 3, the cylinder 3 is fixed on the top of the workbench 1 through the bracket 2, its piston rod 31 faces down and is located directly above the receiving groove 101, and the piston rod 31 is fixedly connected with the connecting frame 10;

[0024] Clamping unit, the clamping unit is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com