Electric servo automatic soldering pliers

An automatic welding and electric servo technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low control accuracy and welding efficiency, insufficient compatibility of welding robots, and low degree of automation, etc. High welding efficiency, easy disassembly, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

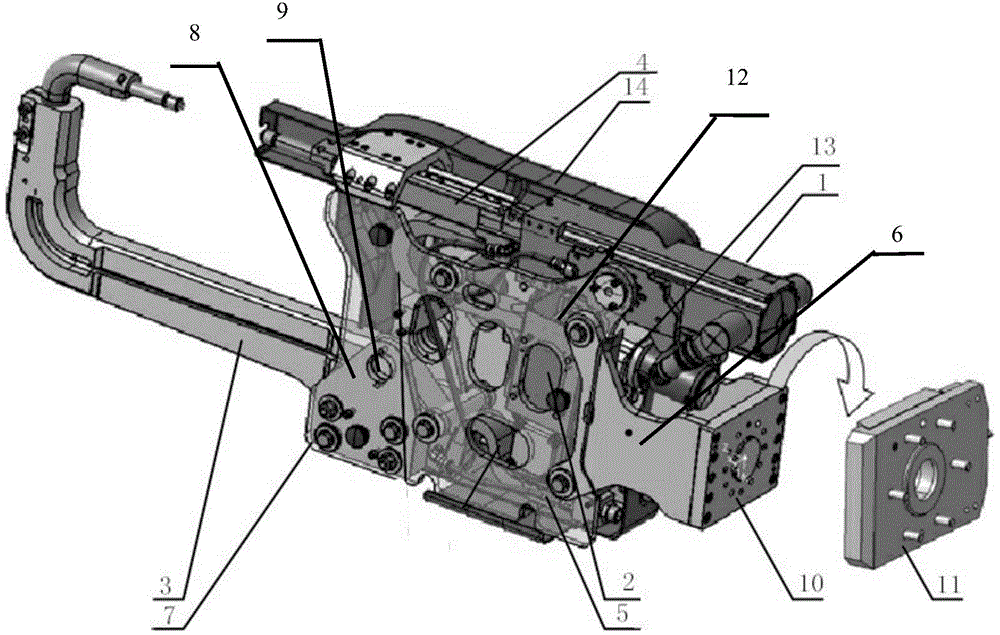

[0014] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown: an electric servo automatic welding tongs of this embodiment, including a servo motor 1, a rectifier module 2, a stationary arm 3, a boom 4, a cooling circuit 5 and a clamp body 6, the servo motor 1 is connected to the boom 4 And the boom 4 is driven to move in a straight line, the two sides of the clamp body 6 are provided with fixed aluminum plates 7, and the servo motor 1, the rectifier module 2, the static arm 3, the boom 4, and the cooling circuit 5 are all located between the fixed aluminum plates 7 A stationary arm fixing plate 8 and a boom rotating shaft 9 are arranged between the fixed aluminum plates 7, and a robot connecting unit 10 is arranged at the rear end of the caliper body 6, and a tool changing device 11 is arranged on the robot connecting unit 10.

[0015] The rectifier module 2 includes a transformer 12 connected to an electri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap