Auxiliary roller support device

An auxiliary support and roll technology, which is applied in the direction of keeping the roll equipment in an effective state, metal rolling, metal rolling, etc., can solve the problems of increasing the distance between the racks, reducing the yield of steel pipes, and bulky equipment, etc., to achieve Higher finish rolling temperature, lower maintenance cost, and shorter time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

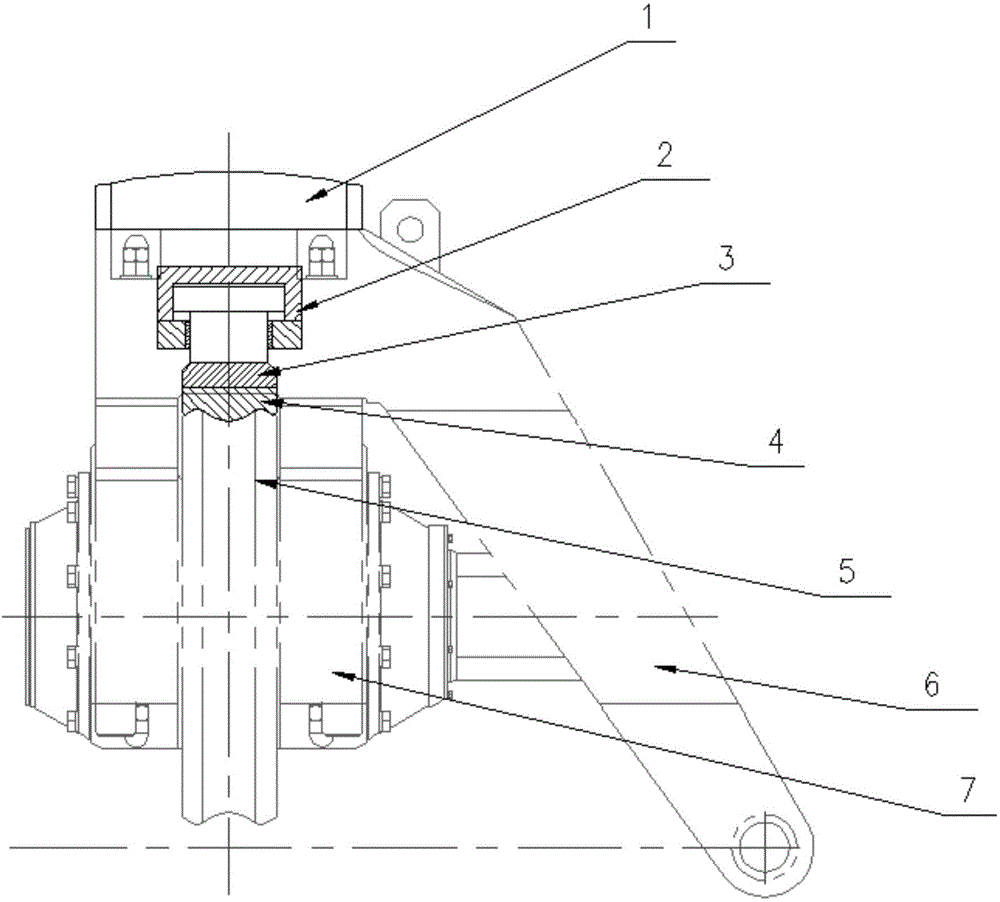

[0020] Such as figure 1 As shown, the roll auxiliary support device in this embodiment includes a pressing member and a pressing mechanism 2 for pressing the pressing member against the roll 5 . In this embodiment, the pressing part is a sliding block 4, the pressing mechanism 2 is a hydraulic cylinder, the sliding block 4 is slidingly matched with the roll 5, the sliding block 4 is installed on the hydraulic cylinder, and the sliding block 4 is tightly stretched out by the hydraulic cylinder. Press against the roll surface of roll 5. Of course, the depressing mechanism 2 can also be a screw jack or an electromagnet that repels each other, or even an electric push rod or an electric cylinder, as long as it can realize that the sliding block 4 is tightly pressed against the roller surface of the roll 5. .

[0021] Take the side swing roll gap adjustment mechanism as an example. The roll auxiliary support device is installed between the roll 5 and the pressure head 1, specifi...

Embodiment 2

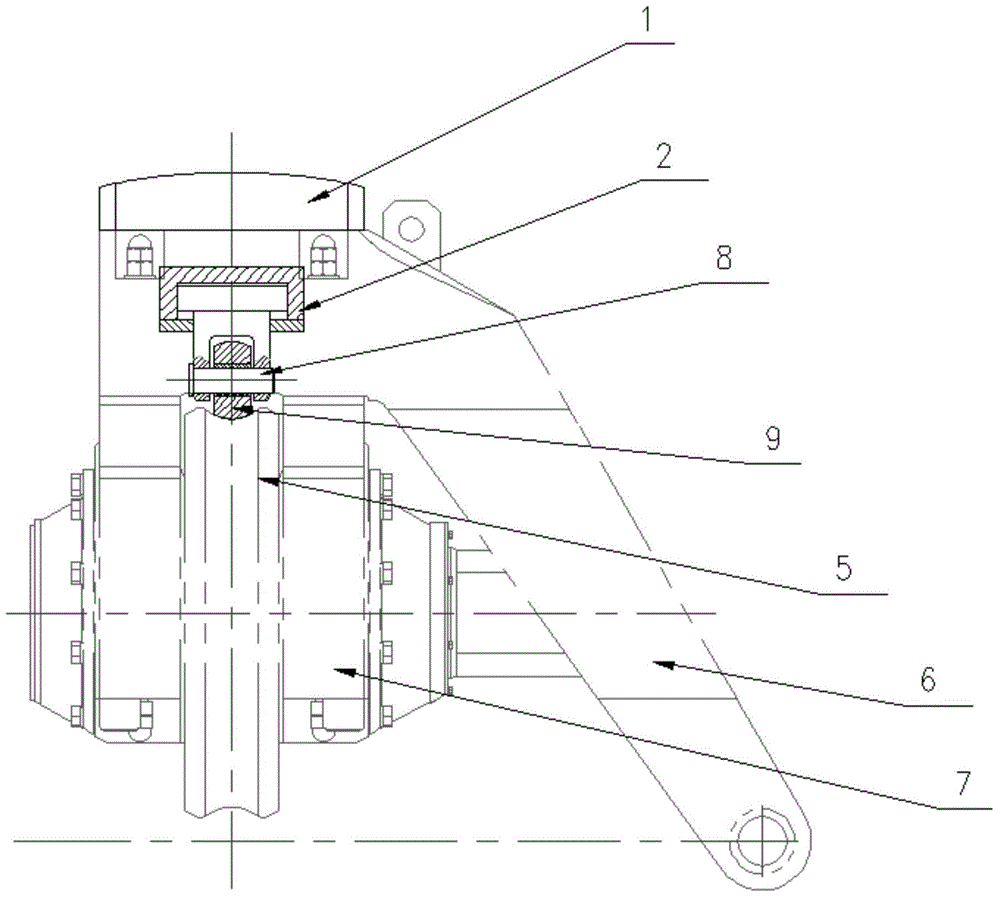

[0029] Such as figure 2 As shown, in this embodiment, the pressing member is a roller 9, and the roller 9 is sleeved on the connecting shaft 8 fixed on the pressing mechanism 2, and a bearing is provided between the roller 9 and the connecting shaft 8. Since the roller 9 and the roller 5 are in rolling fit, the wear of the roller 5 and the roller 9 is reduced, and the service life of the equipment is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com