Automatic cleaning device for inner wall of porcelain bottle of high-voltage circuit breaker

A high-voltage circuit breaker and automatic cleaning technology, applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of improving production efficiency, reducing labor intensity, and increasing safety production coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

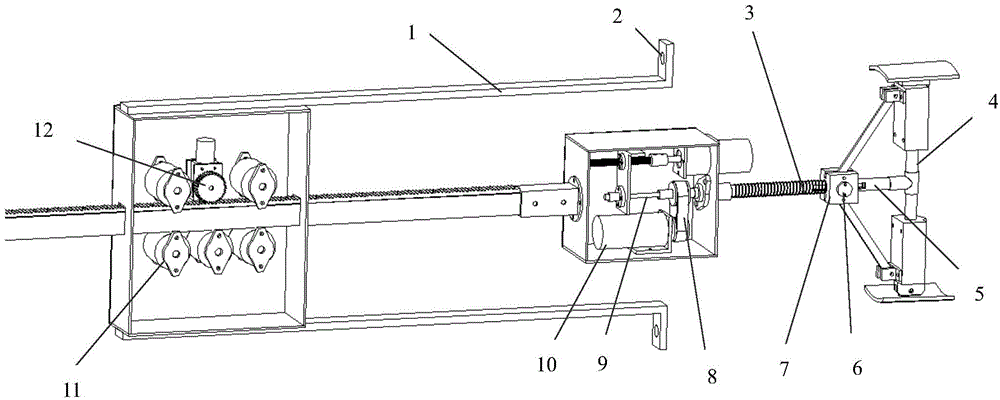

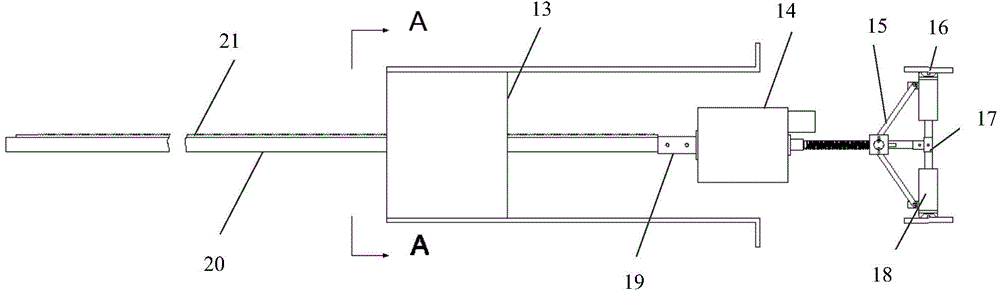

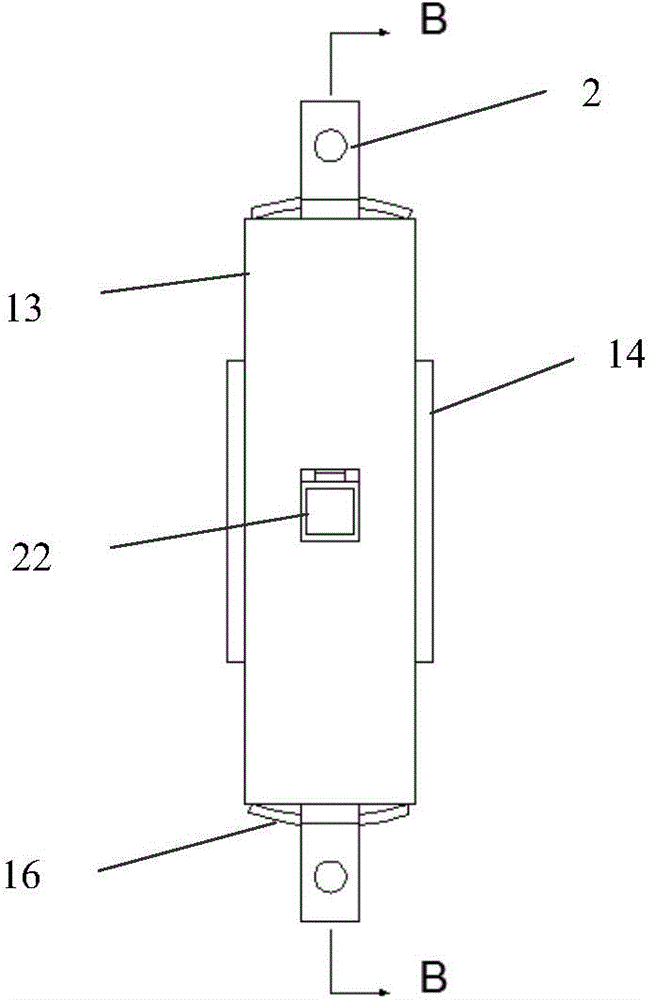

[0029] refer to Figure 1 to Figure 9 , an automatic cleaning device for the inner wall of a high-voltage circuit breaker porcelain bottle, comprising a cleaning mechanism, a rotation control mechanism for controlling the rotation of the cleaning mechanism, and a translation control mechanism for controlling the translation of the cleaning mechanism;

[0030] The cleaning mechanism includes a hollow main shaft 5, a main slider 7, an auxiliary slider 18 and a pumping rod 9, the front end of the hollow main shaft 5 is connected to one end of the slide bar, and the rear end of the hollow main shaft 5 is connected to the rotation control Mechanism connection, the slide bar is vertically arranged with the hollow main shaft 5, the auxiliary slide block 18 is installed on the other end of the slide bar and forms an up and down sliding pair with the slide bar, and the main sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com