Method for producing special-purpose modified mineral materials for black-odor rivers

A technology of mineral materials and production methods, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of high cost of black and odorous river treatment materials and affect wide use, and achieve low cost and low cost The effect of cost purification treatment and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

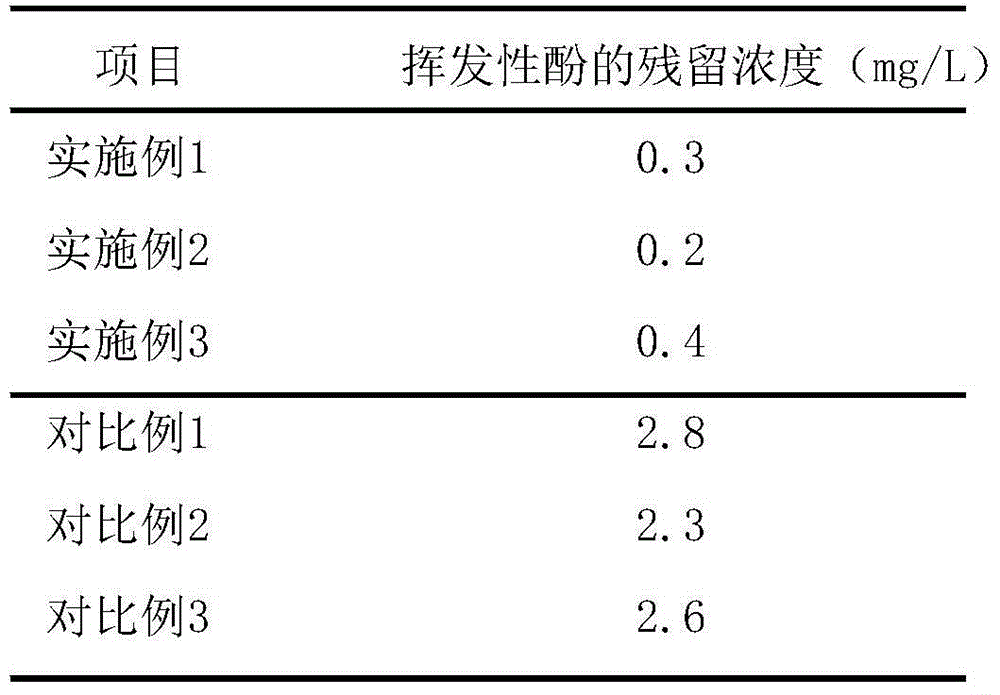

Examples

Embodiment 1

[0026] This embodiment relates to a production method of special modified mineral materials for black and odorous river courses, which consists of the following steps:

[0027] Step 1, drying the attapulgite clay, zeolite, and bentonite raw ore until the moisture content is 20%, then mixing them according to the weight ratio of 2:1:1, and coarsely crushing them into a particle mixture with a particle diameter of 4mm;

[0028] Step 2, adding calcium nitrate equivalent to 5% of the weight of the granular mixture and lanthanum chloride equivalent to 1% of the weight of the granular mixture into the granular mixture, and fully mixing to obtain mixed small particles;

[0029] Step 3, spraying water to the mixed small particles to adjust the water weight content to 32%, and extruding it into a sheet-like clay mixture with a pair of rollers and a three-roller with a distance of 1mm;

[0030] Step 4, mixing the flaky clay mixture with polyferric chloride and polyaluminum chloride acco...

Embodiment 2

[0033] This embodiment relates to a production method of special modified mineral materials for black and odorous river courses, which consists of the following steps:

[0034] Step 1, drying the attapulgite clay, zeolite, and bentonite raw ore until the water weight content is 10%, then mixing them according to the weight ratio of 1:1:1, and coarsely crushing them into a particle mixture with a particle diameter of 2mm;

[0035] Step 2, adding calcium nitrate equivalent to 5% of the weight of the granular mixture and lanthanum chloride equivalent to 1% of the weight of the granular mixture into the granular mixture, and fully mixing to obtain mixed small particles;

[0036] Step 3, spraying water to the mixed small particles to adjust the water weight content to 28%, and extruding into a flaky clay mixture with a pair of rollers and a three-roller with a distance of 2mm;

[0037] Step 4, mixing the flaky clay mixture with polyferric chloride and polyaluminum chloride accordin...

Embodiment 3

[0040] This embodiment relates to a production method of special modified mineral materials for black and odorous river courses, which consists of the following steps:

[0041] Step 1, drying the attapulgite clay, zeolite, and bentonite raw ore until the moisture content is 5%, then mixing them according to the weight ratio of 3:1:1, and coarsely crushing them into a particle mixture with a particle diameter of 3mm;

[0042] Step 2, adding calcium nitrate equivalent to 5% of the weight of the granular mixture and lanthanum chloride equivalent to 1% of the weight of the granular mixture into the granular mixture, and fully mixing to obtain mixed small particles;

[0043] Step 3, spraying water to the mixed small particles to adjust the water weight content to 30%, and extruding it into a sheet-like clay mixture with a pair of rollers and a three-roller with a distance of 1 mm;

[0044] Step 4, mixing the flaky clay mixture with polyferric chloride and polyaluminum chloride acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com