Improved sole pressing machine for shoemaking

The technology of a bottom press and a bottom frame is applied in the direction of shoe-making machinery, footwear, and adhesive shoe parts, etc., which can solve the problems of reducing the pass rate, unevenness, affecting the quality of shoes, etc. The effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

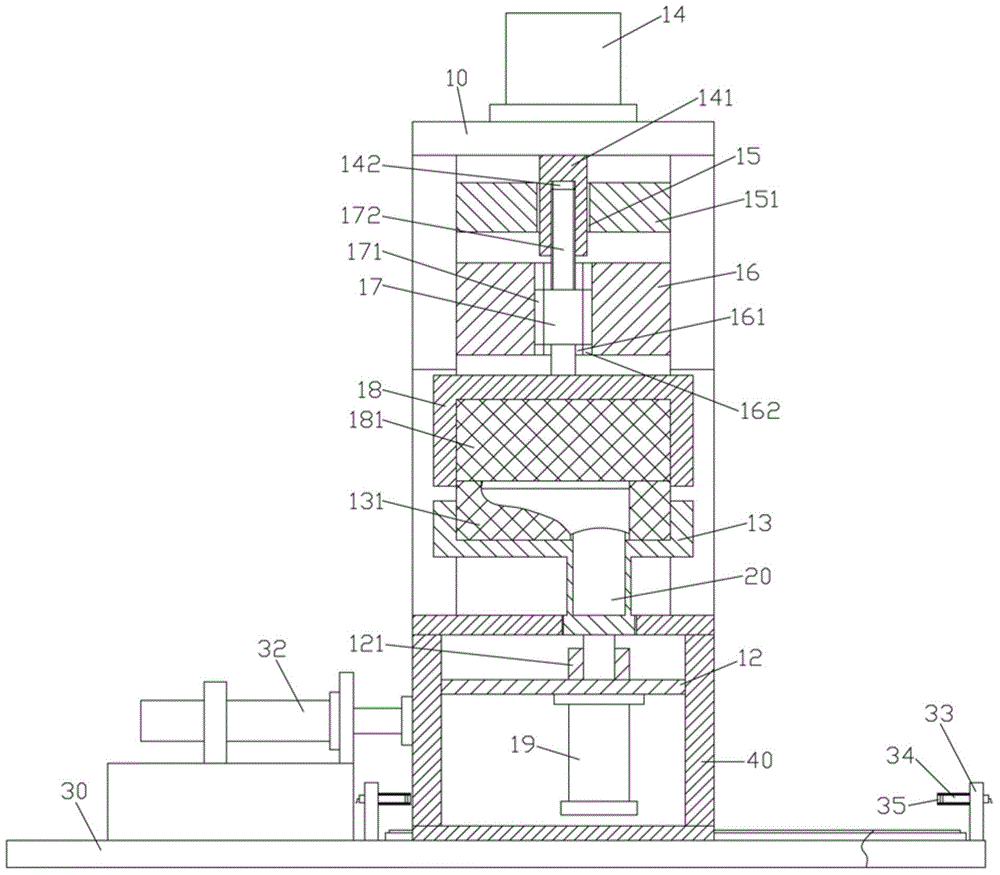

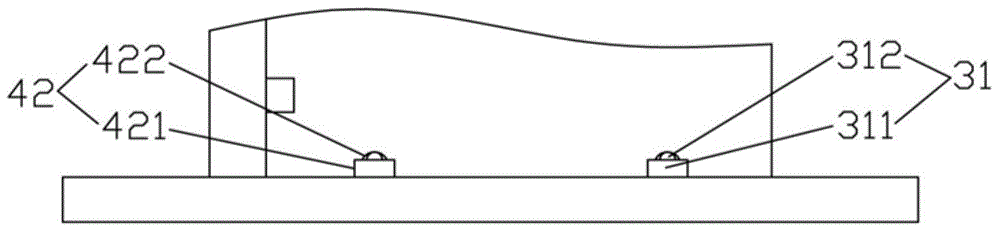

[0020] Example: see Figures 1 to 4 As shown, an improved shoe-making bottom machine includes a shoe-making bottom frame 10 and a main bottom plate 30. 10, the front part of the back plate 200 of the shoe-making chassis 10 has a transverse protruding strip 191, and the back of the lower box body 40 has a transverse groove 41, and the transverse protruding strip 191 is inserted into the transverse groove 41. The bottom surface of the lower box body 40 has a bottom surface sliding groove 42, a sliding bar 31 is fixed on the top surface of the main base plate 30, the sliding bar 31 is inserted and sleeved in the bottom sliding groove 42, and a support plate 12 is fixed inside the lower box body 40. The push cylinder 19 is fixed on the support plate 12, and the push rod of the push cylinder 19 protrudes upwards from the support plate 12 and is fixed with a shoe last lower fixed cover 13. The shoe last lower fixed cover 13 is on the upper part of the lower box body 40, and the shoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com