Plant cultivation apparatus

A cultivation device and plant technology, applied in the field of plant cultivation devices, can solve problems such as complex equipment, increased number of spreading, and fouling of constituent components, and achieve the effects of suppressing complexity and preventing fouling or corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

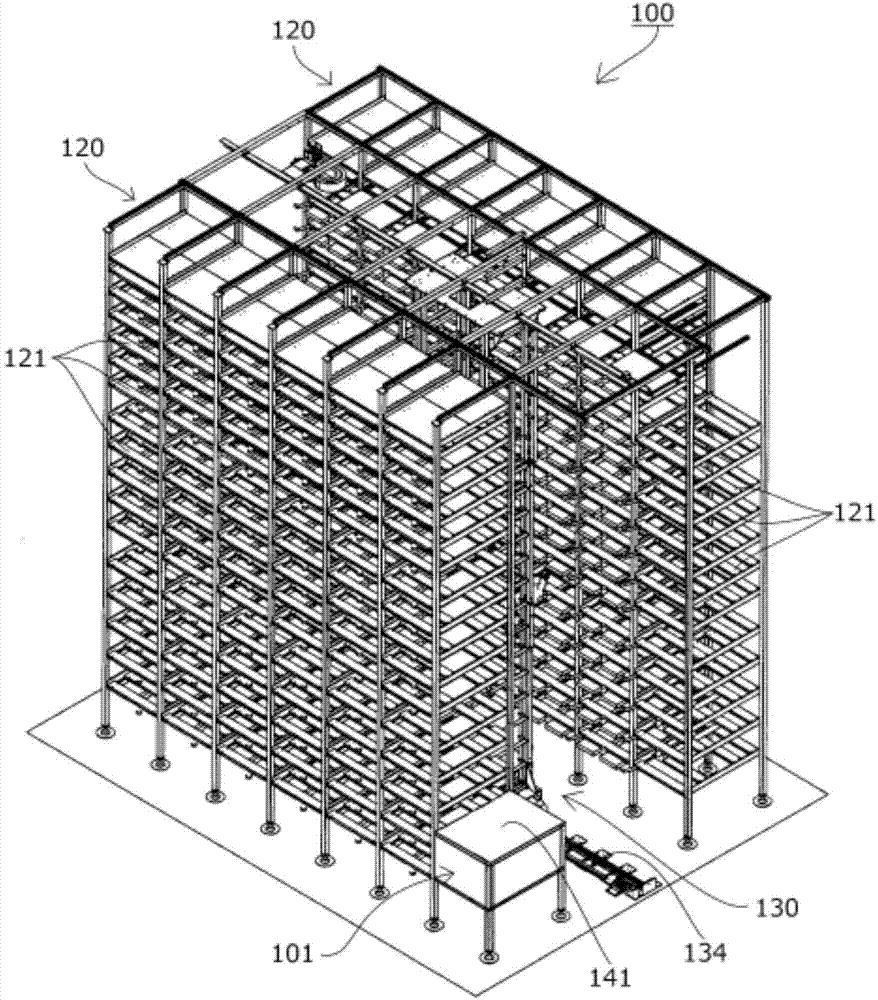

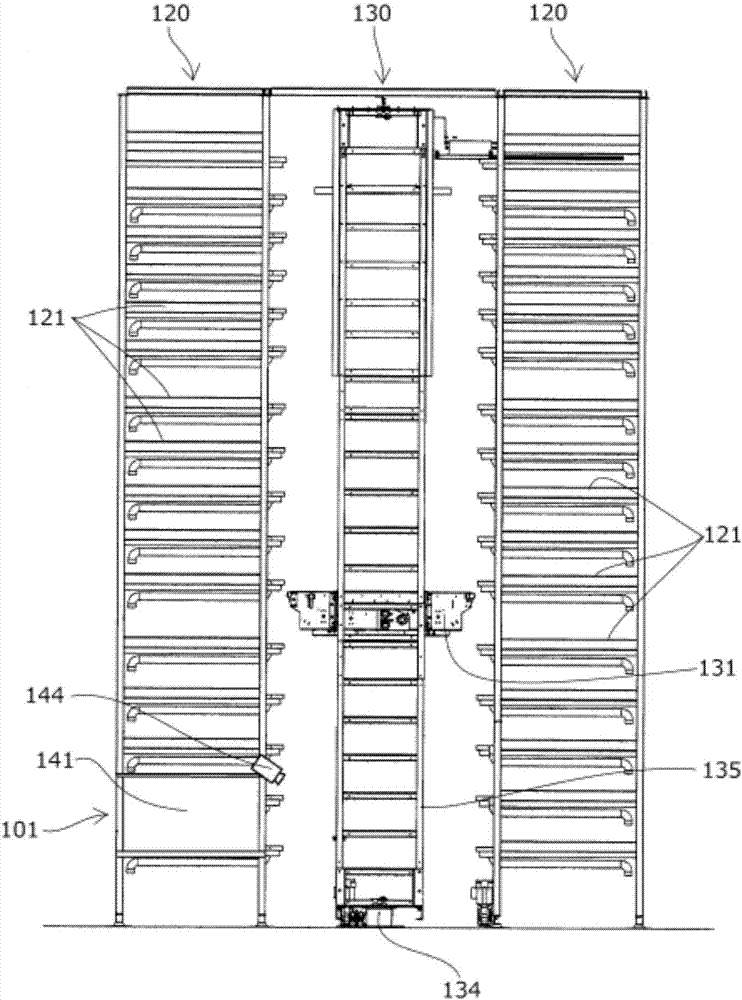

[0051] according to Figure 1 to Figure 4 The plant cultivation device according to the first embodiment of the present invention will be described.

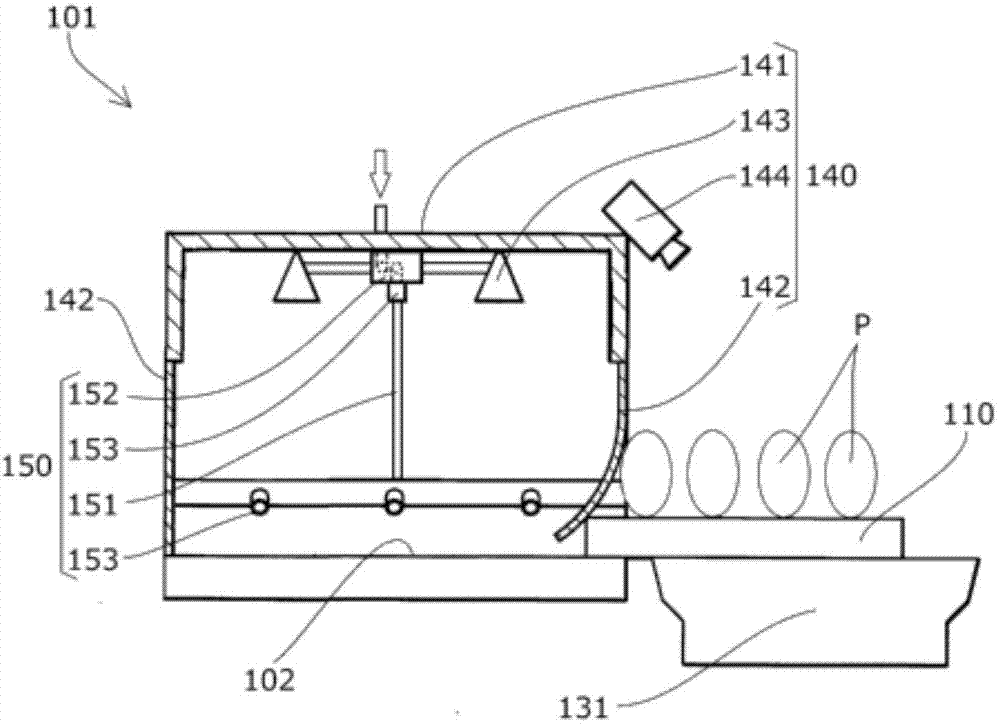

[0052] The plant cultivating apparatus 100 according to this embodiment is performed by accommodating the cultivating pots 110 holding the plants P on two cultivating frames 120 in which a plurality of cultivating shelves 121 are aligned horizontally and vertically. cultivation.

[0053] Two cultivation frames 120 are installed at intervals in parallel, and the transfer unit 130 is provided between the two cultivation frames 120 .

[0054] The transfer unit 130 has: a moving guide rail 134, which is arranged on the ground between two cultivation frames 120; a lifting guide 135, which can move on the moving guide rail 134 in the horizontal direction; and a mobile platform 131, which can move along the lifting guide 135 is movable in the vertical direction.

[0055] The cultivation pot 110 holding the plant P is transported by ...

Embodiment 2

[0080] according to Figure 5 The spreading unit 240 of the plant cultivation apparatus according to the second embodiment of the present invention will be described.

[0081] The spreading unit 240 of the plant cultivating device involved in the present embodiment is arranged on the mobile platform 231, that is, the moving platform 231 is provided with a partition member 241 forming a compartmentalized space above the cultivation pot 210, and a spreading unit 241 is arranged inside the space. The nozzle (not shown) is provided with an optical sensor 244 above the partition member 241 .

[0082] The structure other than the spraying unit 240 is the same as that of the above-mentioned first embodiment except that the piping is shared with the watering unit in the work station.

[0083] According to this embodiment, since there is no need to transport the cultivation pot 210 to the work station when performing the spreading work, the spreading work can be carried out quickly, s...

Embodiment 3

[0086] according to Figure 6 , Figure 7 The spraying unit 340 of the plant cultivation apparatus according to the third embodiment of the present invention will be described.

[0087]The spreading unit 340 of the plant cultivating apparatus according to the present embodiment is applied to a device including a conveyer belt 333 that continuously conveys the cultivation pot 310 in the horizontal direction as a transfer unit.

[0088] The spreading unit 340 is arranged on a prescribed position of the conveyer belt 333, and has: an isolating member 341, which forms a compartmentalized space above the cultivation pot 310; a spreading nozzle 343, which is arranged inside the space; above.

[0089] The partition member 341 is configured so that the length of the cultivation pot 310 in the conveyance direction is smaller than that of the cultivation pot 310 , and is configured so that the cultivation pot 310 passes while being conveyed continuously without stopping.

[0090] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com