Capillary column system capable of increasing open tubular column sample loading quantity by variable-diameter packing column

A capillary column and packed column technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of large connection and execution volume, unfavorable promotion, and influence on the repeatability and separation efficiency of the column system, so as to improve the detection sensitivity and repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

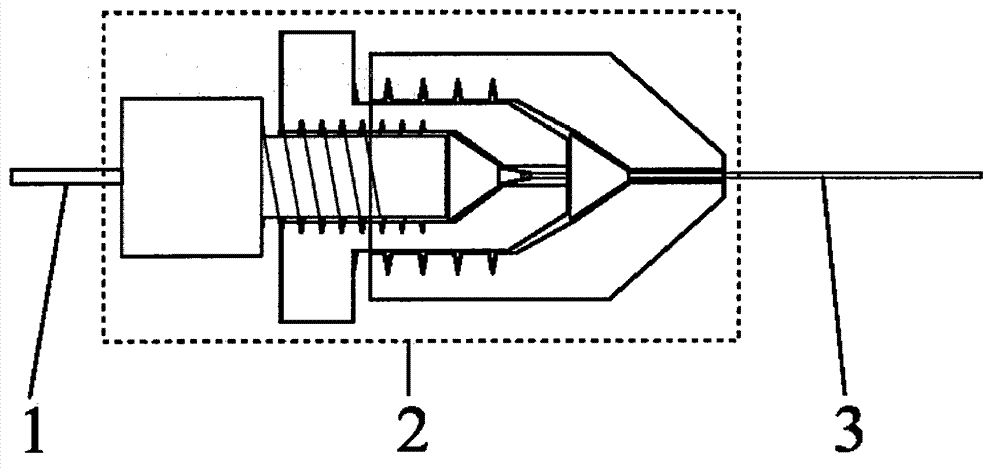

[0023] Preparation of the variable-diameter capillary column system: take a quartz capillary with an inner diameter of 320μm, and under heating conditions, draw the outlet end thin to prepare a variable-diameter capillary with an inlet end of 320μm and an outlet end of 50μm at the outlet tip After the stopper is burnt, 300 mg / mL ion exchange resin solution is filled into the variable diameter capillary column, and the length of the packed column is controlled to be 3 cm to prepare a variable diameter capillary packed column (1). Fix the reduced-diameter packed column (1) at the inner finger-tight joint (a) of the connecting piece (2); the C18 open-tube column (3) with an inner diameter of 50μm and a column length of 100cm passes through the outer finger-tight joint (b) and The tip of the variable-diameter packed column is connected without dead volume, and the capillary column system of the present invention is obtained.

[0024] This capillary column system is used for protein s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com