Detecting device for positive and negative surfaces of valve seat ring

A technology for detection devices and valve seat rings, which is applied in the direction of measuring devices, optical devices, instruments, etc., and can solve the problems of high precision requirements and limitations of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings and embodiments.

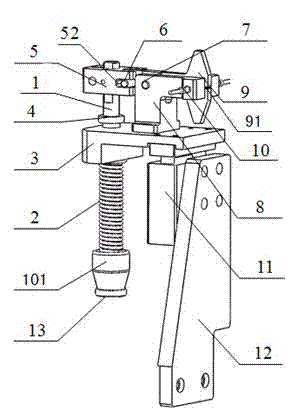

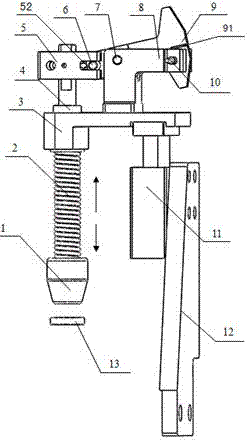

[0025] Such as figure 1 with figure 2 As shown, the main bracket 12 of the detection device is the skeleton of the whole device and bolted to the detection site. The cylinder of the cylinder 11 is fixed to the main bracket 12 by bolts. The piston rod end of the cylinder 11 is bolted to the bottom of the right end of the bracket I3. The left end of I3 is provided with a through hole in the up and down direction. The detection rod 1 penetrates into the through hole and can move up and down along the through hole in a clearance fit. The detection head 101 of the detection rod 1 is facing the seat ring 13 to be detected, and the detection rod 1 is in The part between the bracket I3 and the detection head 101 is sheathed with a spring 2, and the spring 2 is in a compressed state. The bracket I3 presses down the spring 2 to drive the detection head 101 down to contact the seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com