Descaling and rinsing method for plate heat exchange unit

A technology of plate heat exchange and plate heat exchanger, which is applied in the field of descaling and cleaning of plate heat exchange units, can solve the problems of time-consuming, power consumption, long time of descaling and cleaning, etc. Good effect of dirt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

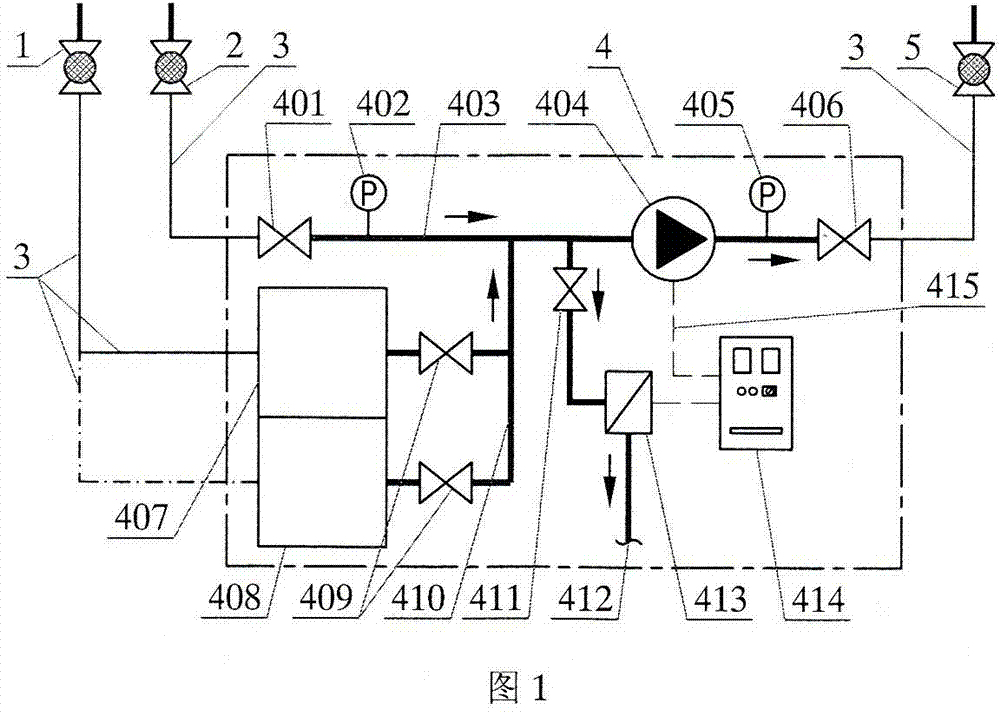

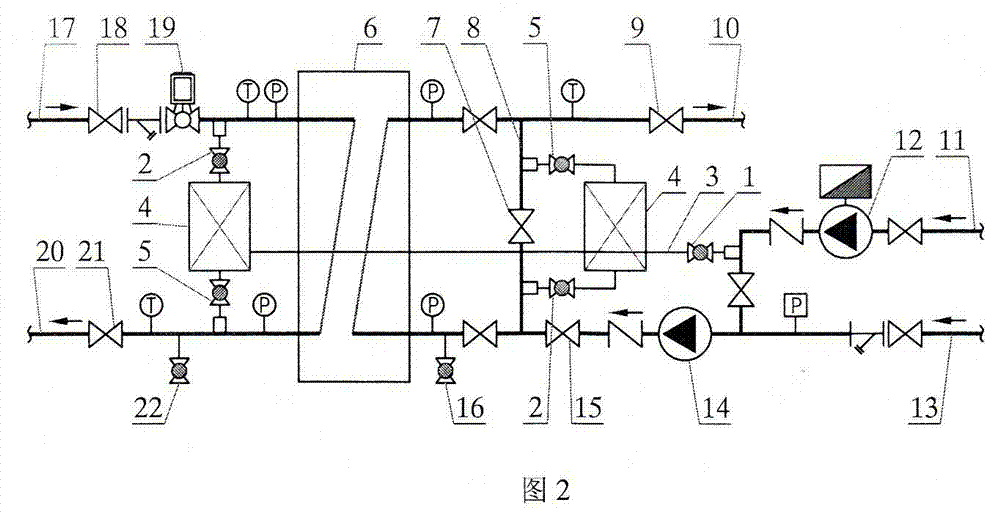

[0019] Attached below figure 1 , attached figure 2 The scale removal and cleaning device for a plate heat exchange unit of the present invention will be described in detail below.

[0020] as attached figure 1 , attached figure 2 As shown, the descaling and cleaning device 4 used in the descaling and cleaning method for a plate heat exchange unit of the present invention mainly consists of a circulation pipe 403, a cleaning pump 404, a corrosion inhibitor dispensing box 407, a descaling agent dispensing box 408, a pH value The detector 413 and the control box 414 are composed, and a cleaning pump 404 is installed on the circulation pipe 403. The circulation pipe 403 is provided with an inlet pressure gauge 402 before the cleaning pump 404, and the circulation pipe 403 is provided with an outlet pressure gauge 405 after the cleaning pump 404. The inlet end of the circulation pipe 403 is also equipped with a water inlet valve 401, the circulation pipe 403 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com