A self-closing buffer packaging bag

A packaging bag, self-closing technology, applied in the field of self-closing buffer packaging bags, can solve the problems of troublesome foam transportation and storage, large volume, increase enterprise cost, etc., and achieve convenient ink printing, good protection performance, air intake smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

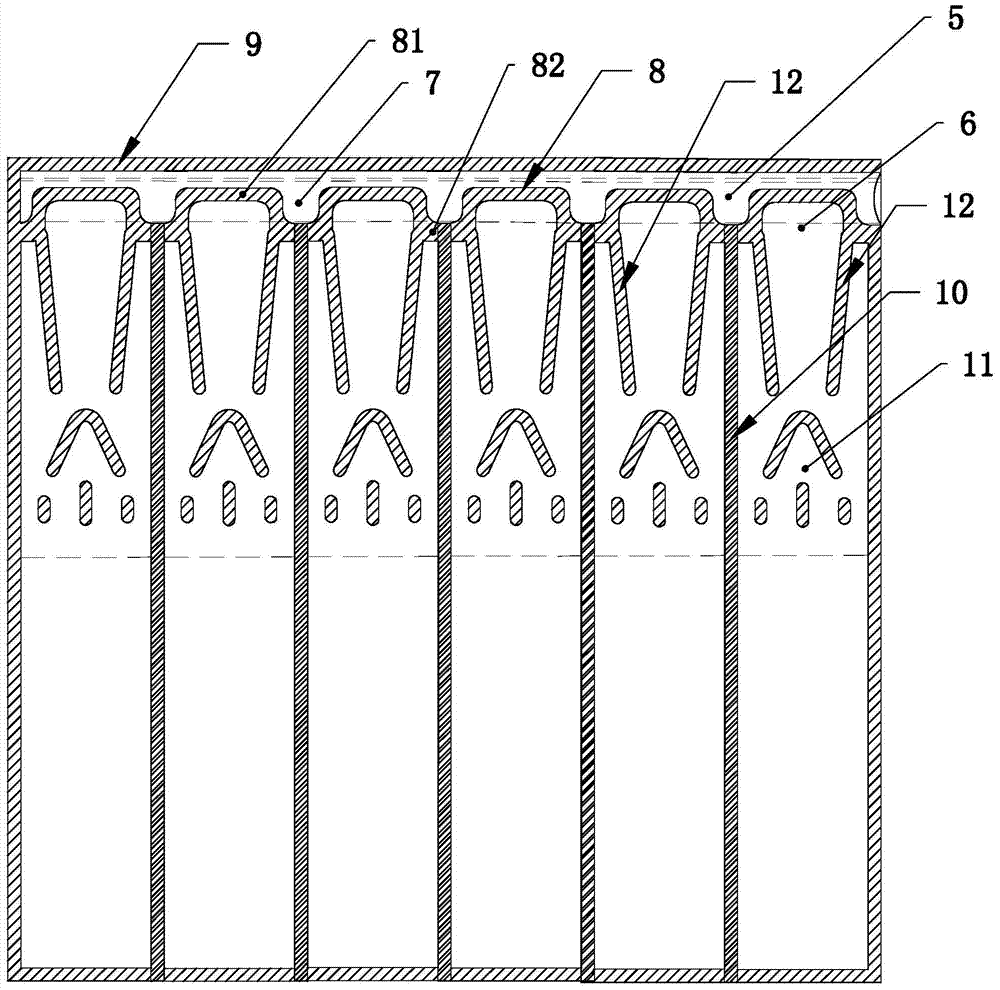

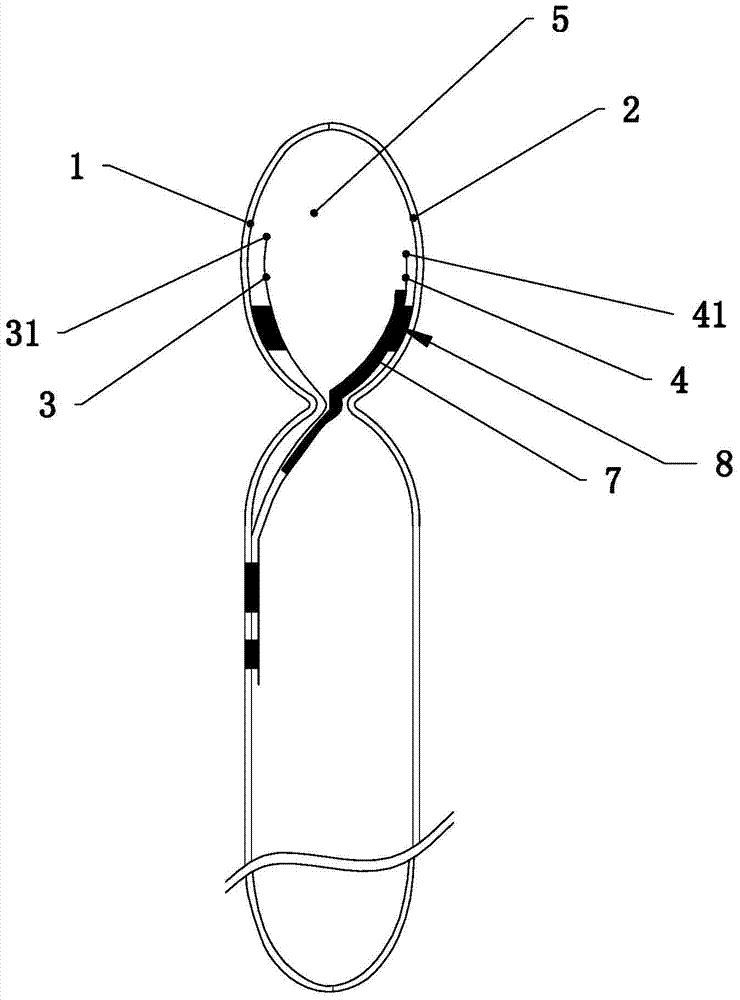

[0015] like figure 1 — figure 2 As shown, a self-closing buffer packaging bag includes two layers of outer films 1, 2 and two layers of inner films 3, 4, and the two layers of inner films 3, 4 are located between the two layers of outer films 1, 2. The two layers of inner membranes 3, 4 are located on the upper side of the two layers of outer membranes 1, 2, and the upper ends 31, 41 of the two layers of inner membranes 3, 4 are set indented on the upper ends of the two layers of outer membranes 1, 2, the Between the outer membranes 1, 2 and the inner membranes 3, 4, a main air channel 5 and a plurality of sub-inflatable channels 6 are formed through heat-sealing lines, and each of the sub-inflatable channels 6 is arranged through the main inflatable channel 5. The above-mentioned technical features are It is also available in the prior art, so it will not be described in detail here. In this embodiment, a heat-resistant strip is coated between the two inner films 3 and 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com