Drill

A technology of drill bit and drill shank, which is applied in the direction of drill bit, drill repairing, drilling tool accessories, etc. It can solve the problems of insufficient drilling performance, increase production cost, and reduce production efficiency, so as to achieve smooth cutting, avoid scrapping, and cut cutting convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

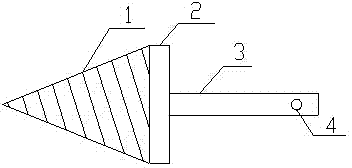

[0018] Reference numerals: 1. Drill point, 2. Drill body, 3. Drill shank, 4. Locating groove

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0020] The structure of the drill bit of the present invention is as figure 1 As shown, a drill bit is composed of a drill point 1, a drill handle 3 and a drill body 2. One end of the drill body 2 is connected to the drill handle 3, and the connection mode between the drill handle 3 and the drill body 2 is welding. The other end of the body 2 is connected with the drill tip 1, and the connection mode between the drill tip 1 and the drill body 2 is welding, and the rear end of the drill shank 3 is provided with a positioning groove.

[0021] The structure of the drill body 2 is a cylinder with a diameter of 5-7cm and a height of 1-2cm. It is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com