Printing method for three-dimensional biological structure with built-in nutrition channel

A three-dimensional biological and nutrient channel technology, applied in medical science, prosthesis, etc., can solve the problem of malnutrition of inner cells, and achieve the effect of being conducive to cell survival and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

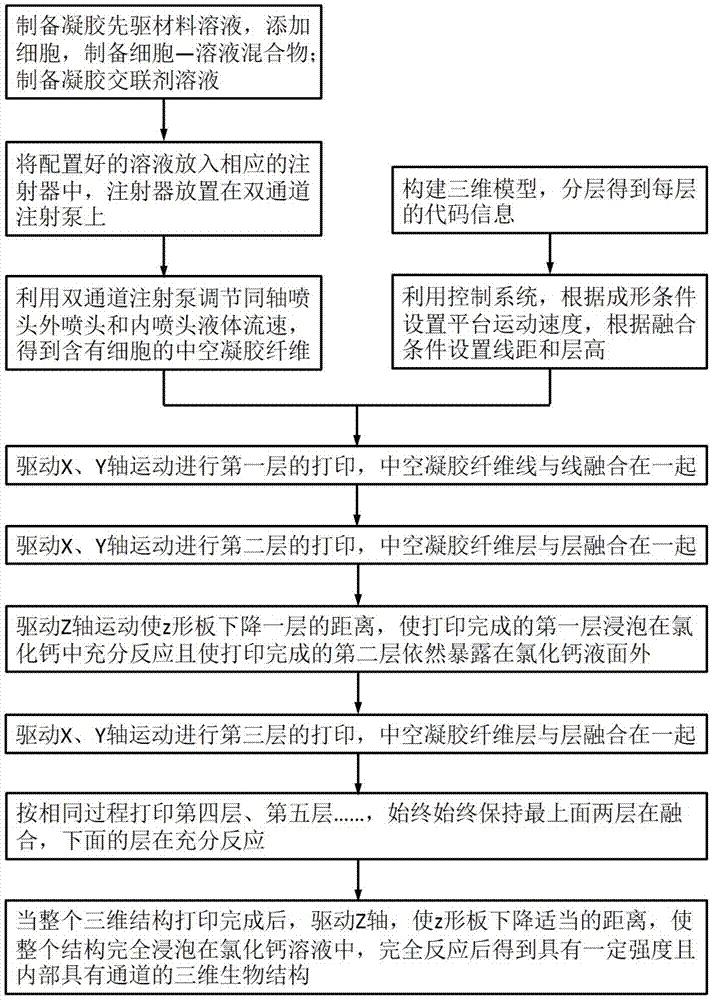

Method used

Image

Examples

Embodiment Construction

[0051] Figure 8 Schematic diagram of the device structure required for the process of the present invention. The whole device includes: a coaxial nozzle 1, a z-shaped plate 2, a liquid storage tank 3, a dual-channel syringe pump 4, a syringe 5 containing a mixture of sodium alginate and cells, and a syringe 6 containing a calcium chloride solution. The coaxial nozzle 1 is fixed on the horizontal driving mechanism. The horizontal driving mechanism generally includes an X-axis driving mechanism and a Y-axis driving mechanism. Driven by the horizontal driving mechanism, the coaxial nozzle 1 can realize reciprocating motion in the directions of x and y axes. , to realize the printing of each layer structure. As the forming platform for printing, the z-shaped plate 2 is fixed on the Z-axis driving mechanism. Driven by the Z-axis driving mechanism, the z-shaped plate 2 can realize reciprocating motion in the z-axis direction to realize the printing of three-dimensional layered str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com