Fungicide composition and application thereof

A composition and sclerotium purification technology, applied in the application, bactericide, biocide and other directions, can solve the problems of sustainable development of unfavorable environment, increase the dosage of drugs, shorten the duration of effect, etc. , the effect of reducing pollution and reducing the dosage of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

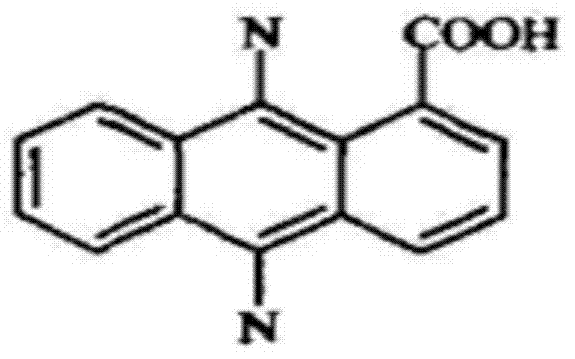

Image

Examples

Embodiment 1

[0051] Example 1: 20.2% Shenzimycin Sclerotin Suspension Concentrate (1:100)

[0052] Components: Shenzimycin 0.2%, Sclerotin 20%, Acrylic Acid-Hydroxypropyl Acrylate Copolymer 3%, Sodium Octylphenol Polyoxyethylene Ether Sulfonate 3%, Ethylene Glycol 6%, XG 0.3%, Silicone defoamer 0.2%, sodium benzoate 0.4%, soft water make up to 100%.

[0053] Preparation method: Mix the components, mix them uniformly by high-speed shearing, and then sand them with a sand mill for 2-3 hours, so that the average particle size reaches 1-5 microns, and then 20.2% Shenzimycin bacteria can be prepared. Nuclear net suspending agent.

Embodiment 2

[0057] Embodiment 2: 25.5% Shenzimycin Sclerotin wettable powder (1:50)

[0058] Components: Shenzimycin 0.5%, Sclerotinia 25%, Sodium Lauryl Sulfate 5%, Sodium Lauryl Sulfate 5%, White Carbon Black 6%, Light Calcium Carbonate supplemented to 100%.

[0059] Preparation method: Mix all the components uniformly, first pass through mechanical pulverization, then jet pulverization, and then mix uniformly to prepare 25.5% Shenzimycin · Sclerotinia wettable powder.

Embodiment 3

[0063] Embodiment 3: 35% Shenzimycin · Sclerotia clean dry suspension concentrate (1:34)

[0064] Components: Shenzimycin 1%, sclerotium 34%, sodium lignosulfonate 8%, sodium lignonaphthalenesulfonate 6%, white carbon black 4%, sodium benzoate 0.2%, talcum powder 100%. An additional 150-200% of deionized water was added during preparation.

[0065] Preparation method: add 1.5-2.0 times the amount of water prepared by the preparation, mix the components, mix them evenly through high-speed shearing, and then sand them with a sand mill for 2-3 hours to make the average particle size reach 1-5 microns, dehydrate After drying, a 35% Shenzimycin·sclerotia net dry suspension can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com