Actuator

A technology of actuators and actuators, which is applied to electric components, engine components, engine control, etc., can solve the problems of heavy casing weight, and achieve the effect of small weight and close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

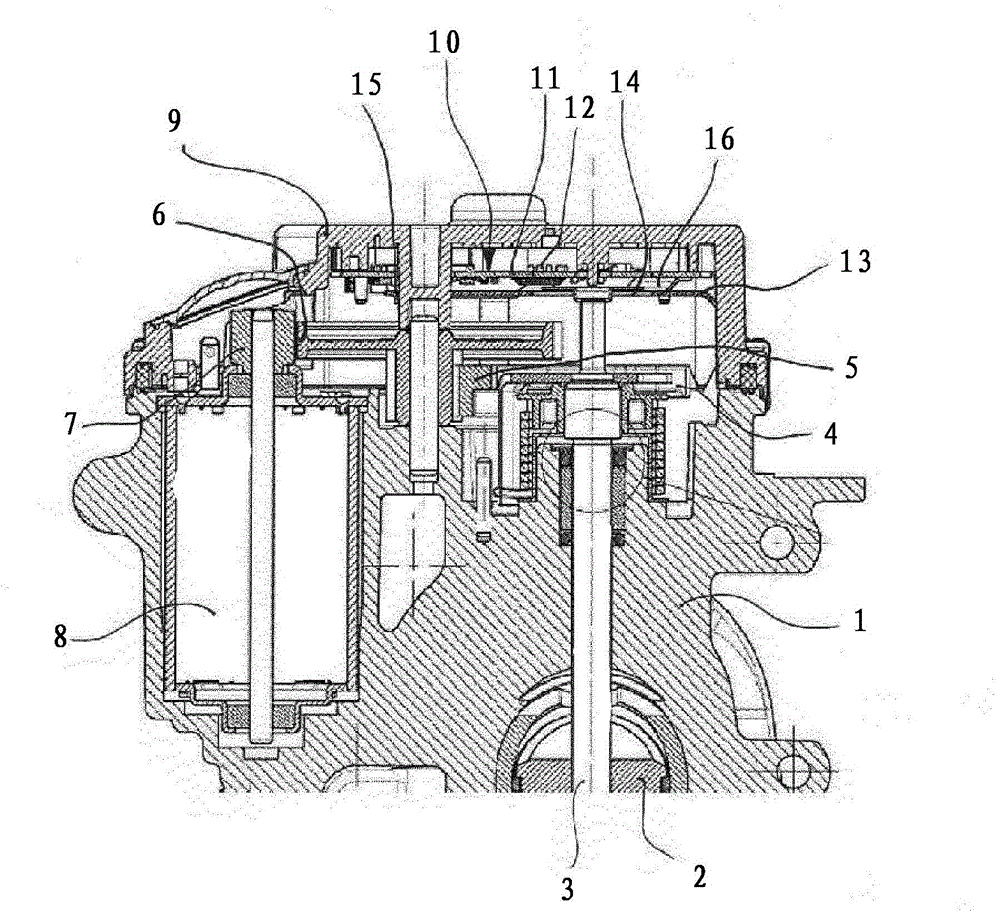

[0023] figure 1 Shown is part of a housing 1 made of aluminum of an actuator in a motor vehicle with an actuator 2 driven by a pinion 7 of an electric motor 8 via a shaft 3 , gears 4 - 6 . The motor 8 is arranged in a chamber of the housing 1 . A plastic cover 9 is connected to the housing 1, wherein the plastic cover 9 covers the area of the motor 8 and the gears 4-6. For controlling the motor 8 as a function of the position of the actuator 2 , an electronic device 10 is provided. The electronic device 10 is composed of a circuit board 11 and electrical structural elements 12 disposed thereon. A metal body functioning as a heat sink 13 is provided between the gears 4 - 6 and the electronic device 10 . In the area of the shafts of the gearwheels 4 - 6 the heat sink 13 has recesses 14 , 15 . The plate 16 of the heat sink 13 is used as a thermal connection surface and is in contact with the electronic device 10 under a preload.

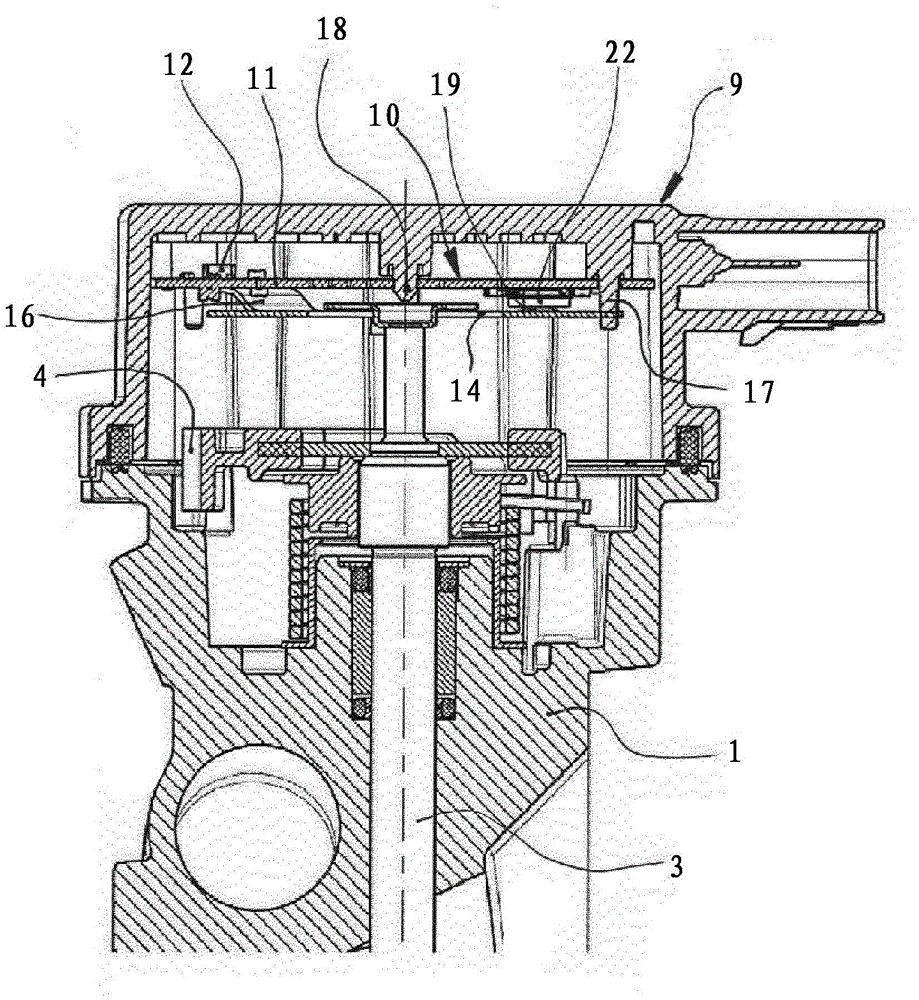

[0024] figure 2 The housing 1 is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com