Independent control method of echo gain inside gate for ultrasonic flaw detector

An independent control, gain control technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, detection of response signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

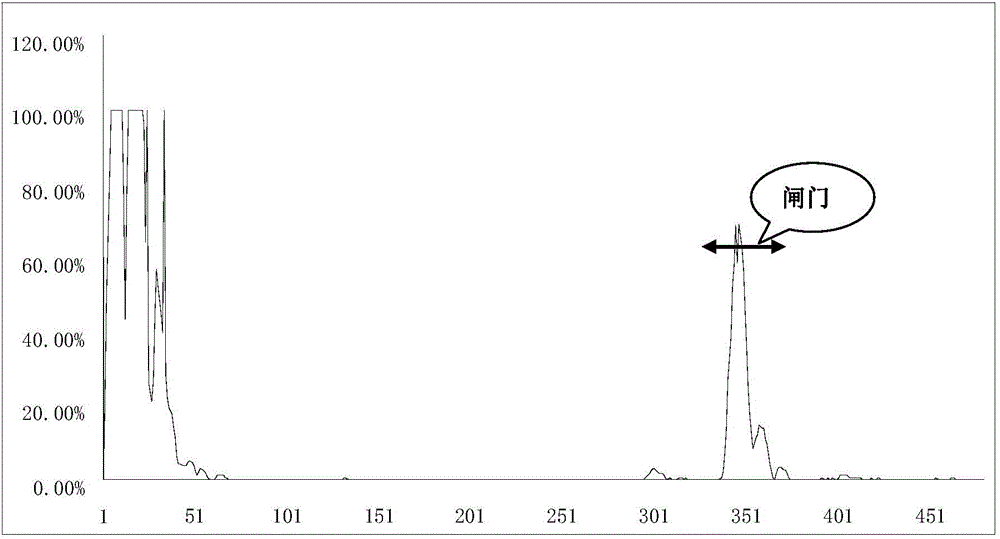

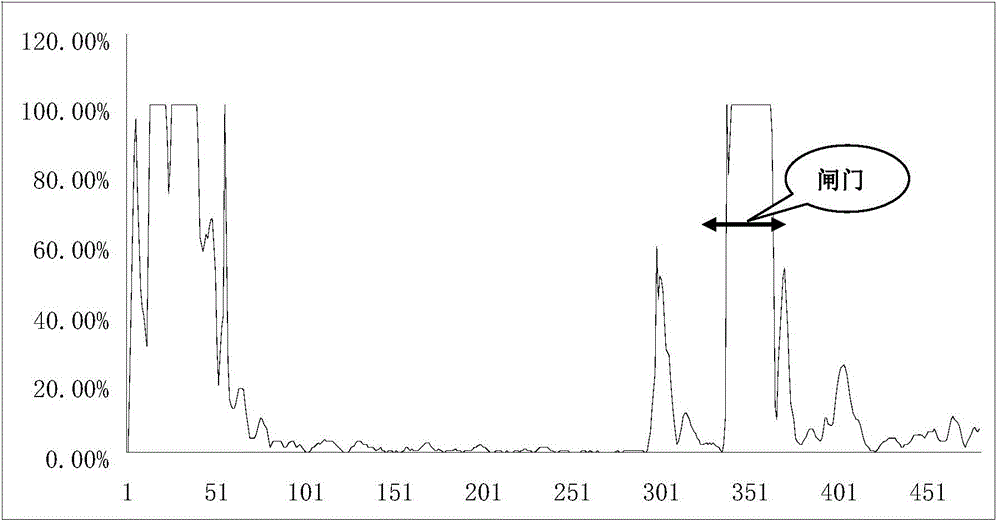

[0019] In view of the fact that most of the existing ultrasonic flaw detectors can only set a single gain value, which cannot meet the requirement of observing the bottom wave and the defect wave at the same time, the present invention provides a high-performance independent control method for the echo gain in the gate. The figure illustrates the present invention in detail.

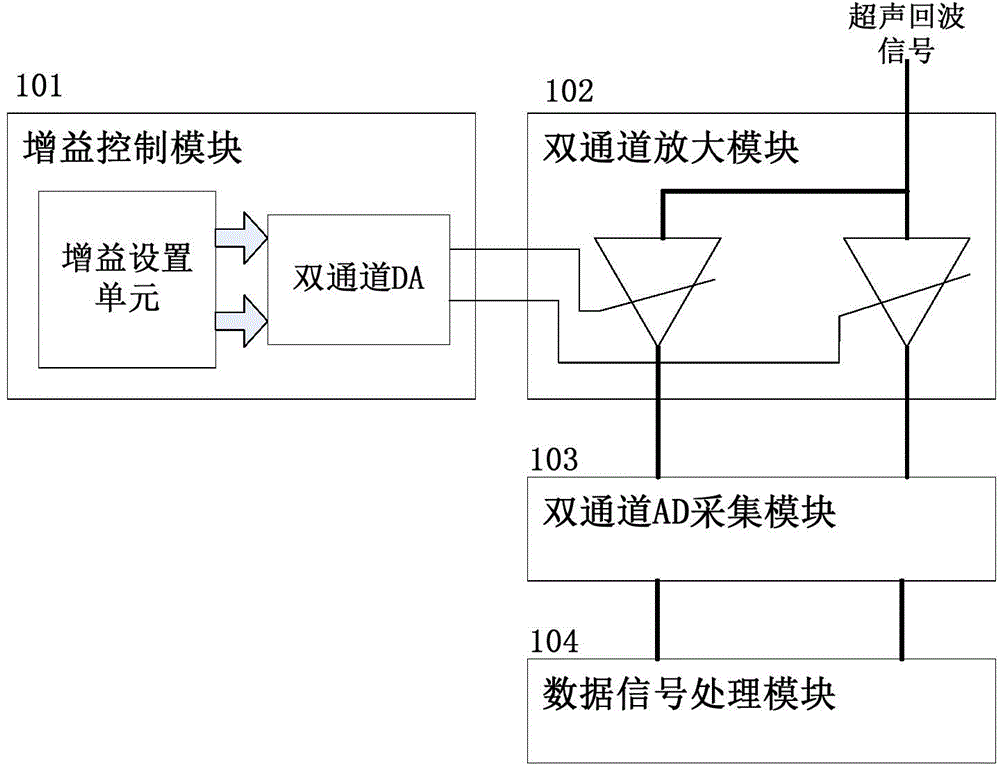

[0020] The structure of the method for independent control of echo gain in the gate provided by this embodiment is as follows: figure 1 As shown, it includes a gain control module 101, a dual-channel amplification module 102, a dual-channel A / D acquisition module 103, and a digital signal processing module 104.

[0021] The gain control module 101 is used to control the gain of the amplification modules at all levels.

[0022] The dual channel amplifying module 102 is used to amplify the normal echo signal and the echo signal in the gate respectively.

[0023] The dual-channel A / D acquisition module 103 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com