Multi-bed linkage fluidized bed roasting furnace

A fluidized bed and roasting furnace technology, applied in the field of stone coal roasting and utilization equipment, can solve the problems of high initial investment, many auxiliary equipment, complex structure, etc., and achieve the effect of strengthening roasting effect, increasing residence time and high roasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

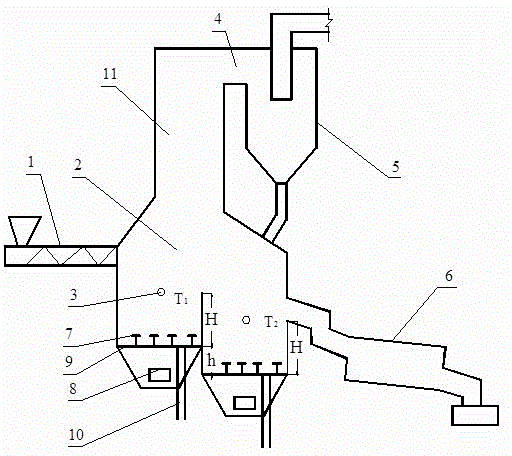

[0013] Such as figure 1 and figure 2 As shown, a multi-bed linkage fluidized bed roaster includes a feeding device 1, a furnace 2, an overhead flue 4 arranged on the top of the furnace, a slag cooling device 6 and a cyclone connected behind the overhead flue Separator 5. Above the furnace 2 is a shrinkable vertical flue 11 . Below the hearth 2, there are more than two (including two) and less than six (including six) calcination beds. The roasting bed of the previous stage and the roasting bed of the subsequent stage are arranged in steps. The height difference h between the previous stage and the subsequent stage of the roasting bed can be equal or different, and the height difference h ranges from 100-300mm. The size of the roasting bed at all levels is adjusted according to the roasting temperature and residence time. According to the feeding and discharging direction as the front and rear directions, the height H of the rear side wall away from the feeding direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com