Composite-material plate joint

A composite material board and composite material technology, applied in the field of joints of composite material boards, can solve problems such as complex and changeable application forms, difficult processing and manufacturing, and complex design technology, and achieve simple and flexible implementation, good versatility, and simple and reliable technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

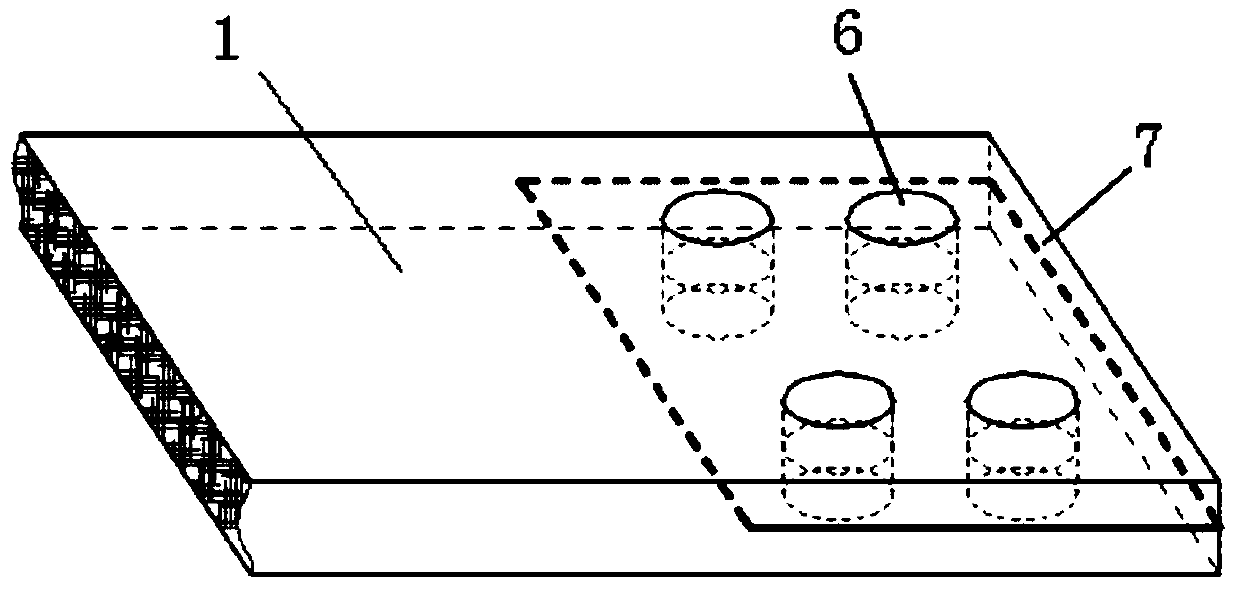

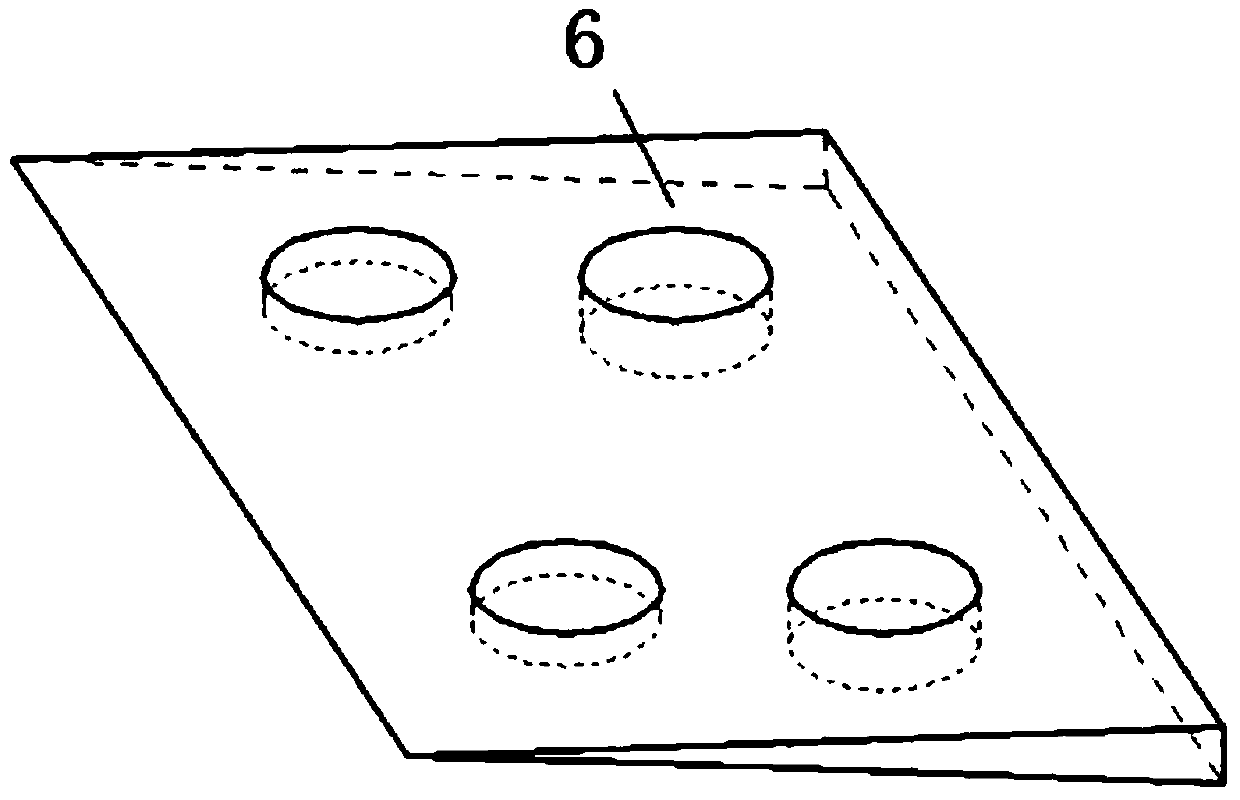

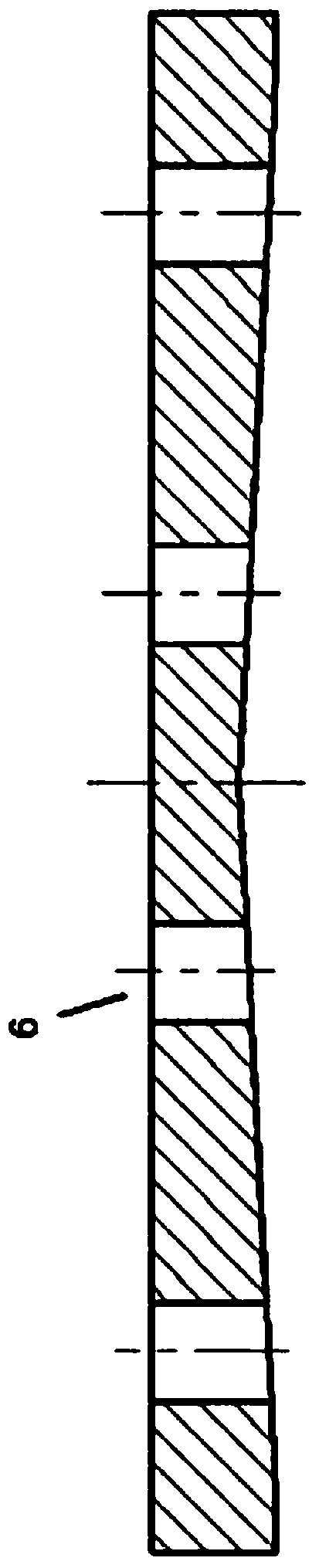

[0033] like figure 1 , figure 2 , image 3 As shown, a group of connecting holes 6 are processed on the end of the composite material plate 1, the metal wedge 2 and the connecting plate 3 by machining, and the positions of the connecting holes 6 correspond to each other for the fixed connection of the bolt 4; A slit 7 is processed along the edge of the composite material plate 1. Since the slit 7 is very narrow, it has little effect on weakening the tensile strength of the composite material plate 1, so it can meet the design requirements. A metal wedge 2 with a symmetrical slope is processed, the width of which is the same as that of the composite material plate 1 , and the length is shorter than the depth of the gap 7 on the composite material plate 1 . In addition, two identical connecting plates 3 are processed, and two symmetrical slopes are processed on one surface of the connecting plate 3, and the overall structure forms a V shape, the slope of which is consistent w...

Embodiment 2

[0037] like Figure 6 As shown, the metal wedge 2 is processed into a cross shape by mechanical processing, and the connecting plate 3 is correspondingly processed into an angle shape, and the slope of the surface that is clamped with the composite material plate 1 and the slope of the metal wedge 2 are guaranteed. unanimous. As described in the method in Embodiment 1, the connection holes 6 are processed at the corresponding positions of the end of the composite material plate 1, the metal wedge 2 and the connecting plate 3, for the fixed connection of the bolt 4; and along the edge of the composite material plate 1 A gap 7 is processed for wedging the metal wedge 2; wherein the cross-shaped metal wedge 2 has a symmetrical slope and the width is the same as that of the composite material plate 1 .

[0038] In the processed gap 7 of the composite material plate 1, and on the wedge surface of the cross-shaped metal wedge 2, evenly coat the adhesive, and then wedge the metal we...

Embodiment 3

[0040] like Figure 7 As shown, for a composite material panel 1 with a thickness of more than 10 mm, a group of symmetrical gaps 7 are processed along the end edge of the panel, and the method in Example 1 is used at the end of the composite material panel 1, the metal wedge 2 The connection hole 6 is processed at the corresponding position of the connection plate 3, which is used for the fixed connection of the bolt 4.

[0041] A metal wedge 2 with a symmetrical slope is processed, the width of which is the same as that of the composite material plate 1 , and the length is shorter than the depth of the gap 7 on the composite material plate 1 . In addition, two identical connecting plates 3 are processed. Two symmetrical slopes are processed on one surface of the connecting plate 3. The overall structure forms a V shape, the length is three times the length of the metal wedge 2, and the width is the same as that of the composite material plate 1. Same width.

[0042] In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com