Metal pickling corrosion inhibitor, and preparation and application of metal pickling corrosion inhibitor

A technology of metal acid and corrosion inhibitor, applied in the preparation of N,N-di--1-phenylethylamine, application of metal pickling corrosion inhibitor in metal pickling corrosion inhibitor, metal pickling corrosion inhibition In the field of pickling agents, it can solve problems such as incalculability, difficulty, and economic loss, and achieve the effect of low concentration of pickling medium and good metal corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

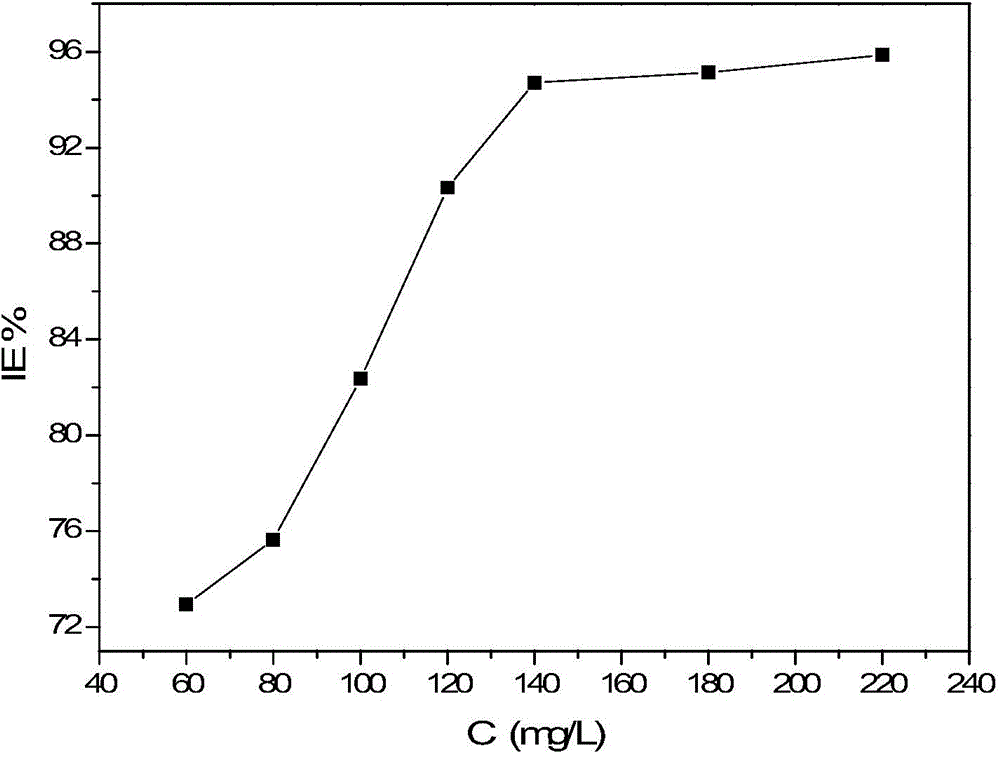

[0035] Example 1: The influence of the concentration of N,N-bis(diphenylphosphino)-(S)-1-phenethylamine on the corrosion inhibition rate of hydrochloric acid pickling metals

[0036] In this case, when the concentration of hydrochloric acid is the same (1mol / L, molar concentration, the same below), different concentrations (60mg / L, 80mg / L, 100mg / L, 120mg / L, 140mg / L, 180mg / L) are added. , 220mg / L) N,N-bis(diphenylphosphino)-(S)-1-phenethylamine (concentration calculation method: N,N-bis(diphenylphosphino)-(S) -1- The mass of phenethylamine divided by the volume of the hydrochloric acid pickling corrosion inhibitor), respectively used for Q235 steel pickling at a temperature of 25℃, to determine the metal acid of each pickling solution at different concentrations of corrosion inhibitor The corrosion inhibition rate is shown in Table 1.

[0037] And the concentration C (mg / L) of N,N-bis(diphenylphosphino)-(S)-1-phenethylamine in the hydrochloric acid lotion is the abscissa, and the c...

Embodiment 2

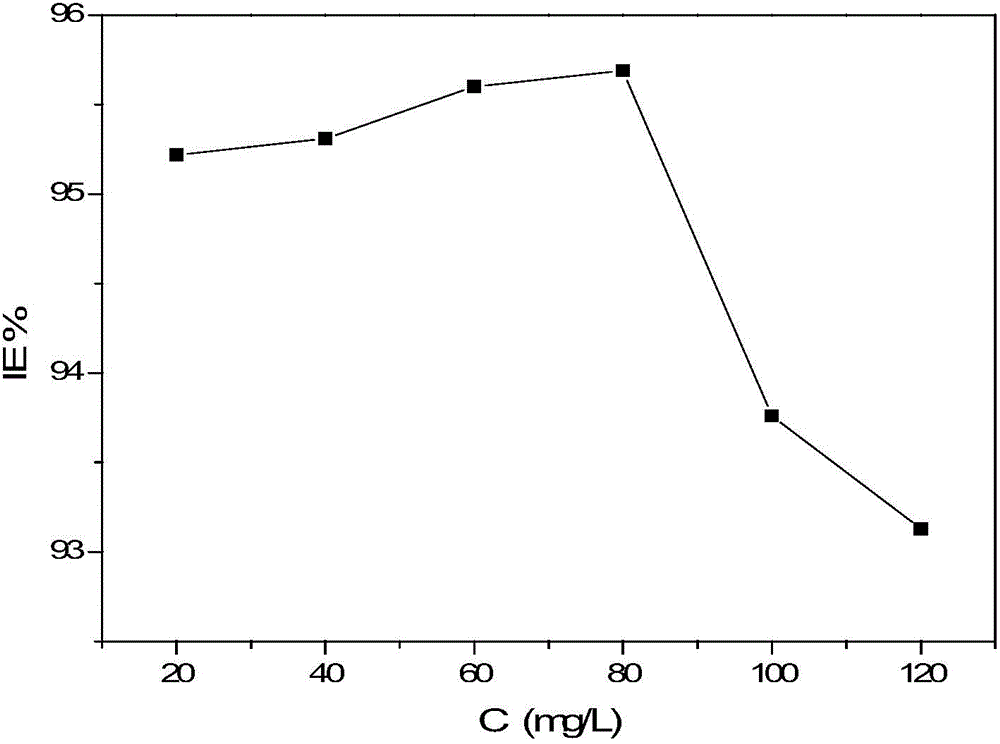

[0041] Example 2: The influence of the concentration of N,N-bis(diphenylphosphino)-(S)-1-phenethylamine on the corrosion inhibition rate of sulfuric acid pickling metals

[0042] In this case, when the sulfuric acid concentration is the same (1mol / L, molar concentration, the same below), adding different concentrations (20mg / L, 40mg / L, 60mg / L, 80mg / L, 100mg / L, 120mg / L) ) N,N-bis(diphenylphosphino)-(S)-1-phenethylamine (concentration calculation method: N,N-bis(diphenylphosphino)-(S)-1-benzene Divide the mass of ethylamine by the volume of the sulfuric acid pickling corrosion inhibitor), and use it for Q235 steel pickling at a temperature of 25℃ to determine the metal pickling corrosion inhibition of each sulfuric acid pickling solution under different concentrations of corrosion inhibitors The results are shown in Table 2.

[0043] And the concentration C (mg / L) of N,N-bis(diphenylphosphino)-(S)-1-phenethylamine in the sulfuric acid lotion is the abscissa, and the corrosion inhibi...

Embodiment example 3

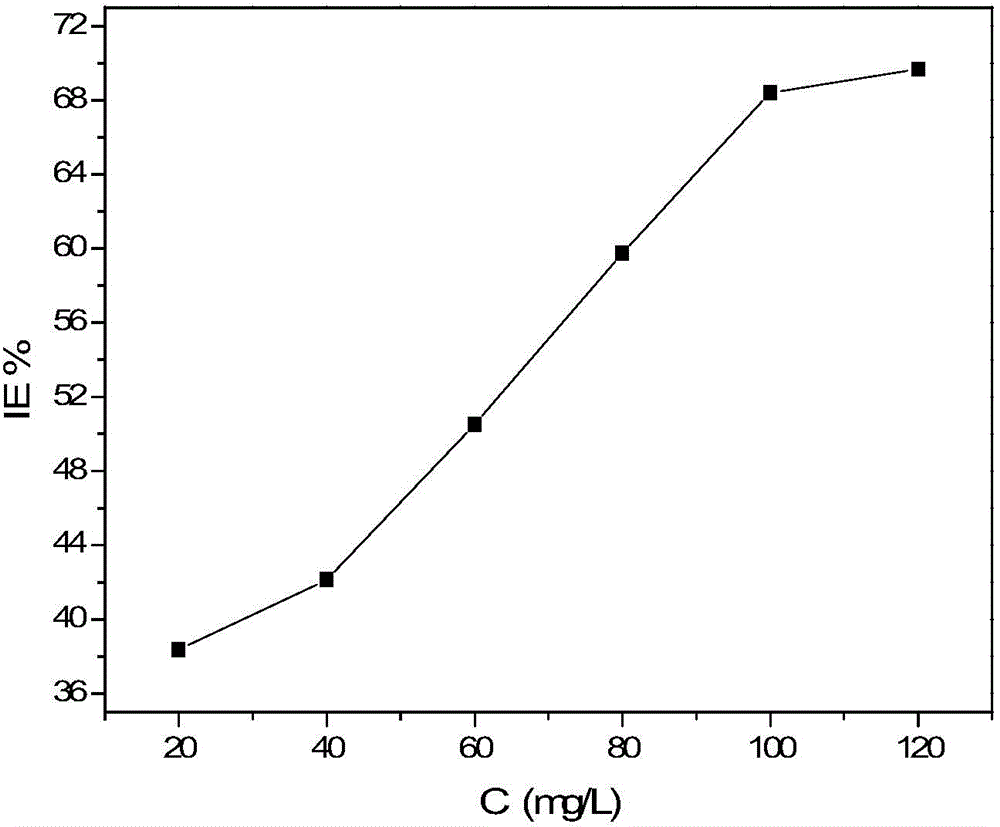

[0047] Implementation case 3: The influence of N,N-bis(diphenylphosphino)-(S)-1-phenethylamine concentration on the corrosion inhibition rate of phosphoric acid pickling metals

[0048] In this case, when the phosphoric acid concentration is the same (1mol / L, molar concentration, the same below), different concentrations (20mg / L, 40mg / L, 60mg / L, 80mg / L, 100mg / L, 120mg / L are added) ) N,N-bis(diphenylphosphino)-(S)-1-phenethylamine (concentration calculation method: N,N-bis(diphenylphosphino)-(S)-1-benzene Divide the mass of ethylamine by the volume of phosphoric acid pickling corrosion inhibitor), and use it for Q235 steel pickling at a temperature of 25℃ to determine the metal pickling corrosion inhibition of each phosphoric acid pickling solution under different concentrations of corrosion inhibitors The results are shown in Table 3.

[0049] And the concentration C (mg / L) of N,N-bis(diphenylphosphino)-(S)-1-phenethylamine in the phosphoric acid lotion is the abscissa, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com