Cable moving winch

A winch and cable technology, which is applied to the arrangement of the take-up reel/photosensitive drum, the winding device, the mechanism of the mainspring, etc., can solve the problems of environmental limitations, inability to change greatly, and structural limitations. Achieve the effect of improving versatility, avoiding restriction, and smoothing the retraction and release of the rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

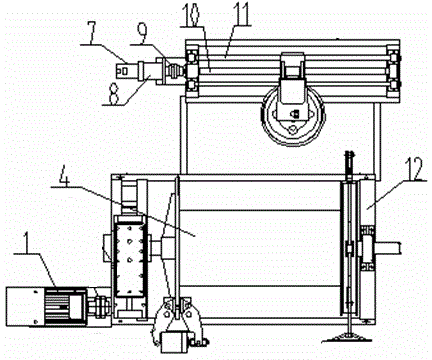

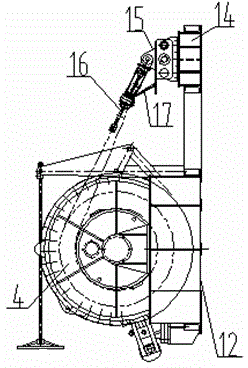

[0020] Such as Figures 1 to 2 A cable moving winch shown includes a frame 12, a reel 4, a drive mechanism 1 and a rope puller. The reel 4 is horizontally arranged on the frame 12 and is driven by the drive mechanism 1. The front of the reel 4 is arranged There is a rope guide; the said rope guide of this device includes a rope guide screw 10 that is driven and rotated by the driving mechanism 1, and a guide shaft 11 parallel to it is provided on one side of the guide shaft 10, and the rope guide wheel assembly can be driven Driven by the mechanism 1, it moves reciprocatingly along the axial direction of the reel 4 in cooperation with the wire screw 10 and the guide shaft 11; It is threadedly connected with the cable screw rod 10, and the other end of the reciprocating shaft seat 14 is slidably matched with the guide shaft 11; Hinged, one end of the elastic member 17 is connected to an end away from the reciprocating shaft seat 14 in the cable support, and the other end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com