Automobile meter needle pressing joint position control module and method

A technology of automotive instrumentation and crimping position, which is applied in the direction of instruments, measuring devices, manufacturing tools, etc., can solve the problems of inaccurate measurement of instrument pointer crimping depth, lack of automatic control process, low production efficiency, etc., and achieve various settings The parameters are convenient and quick, the degree of freedom is high, and the effect required by the product is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

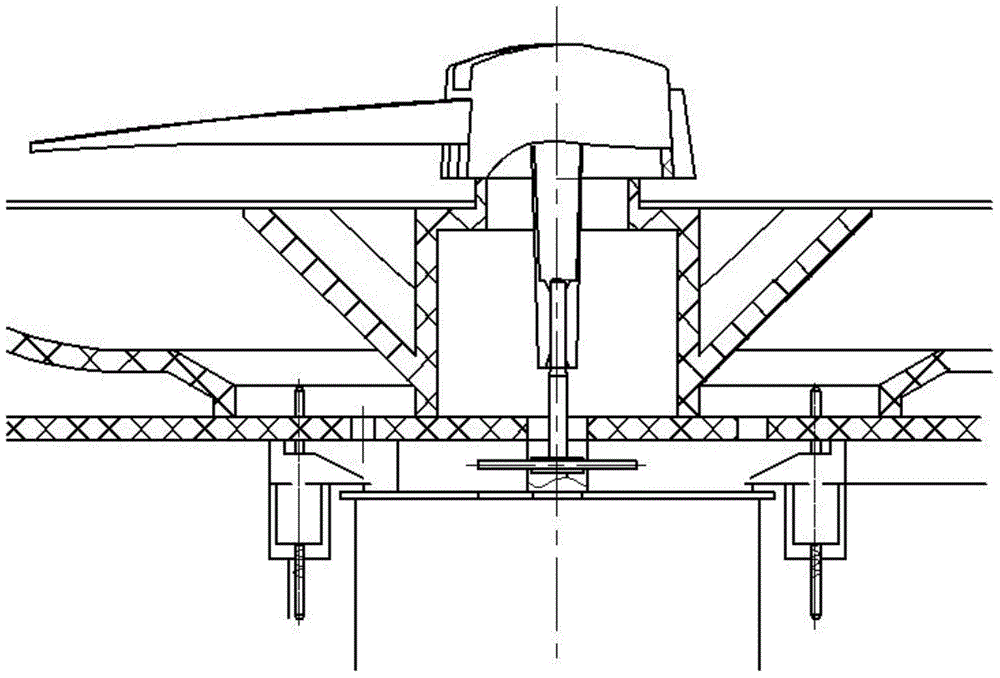

[0050] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, the automobile instrument pointer crimping position control module described in this embodiment includes the following units:

[0051] Pressure signal acquisition unit: collect and store the pressure value between the automobile instrument pointer and the motor shaft according to the sampling period;

[0052] Peak judging unit: judging whether the collected pressure value is greater than Fmax, and starting the decompression signal sending unit when the judging result is yes, and starting the pressure difference calculation unit and the peak judging unit at the same time when the judging result is no;

[0053] Decompression signal sending unit: send a decompression control signal to the pressurization equipment;

[0054] Pressure difference calculation unit: calculate the difference between the maximum pressure and the minimum pressure in the latest T time, that is, the pressu...

specific Embodiment approach 2

[0064] Specific Embodiment 2: This embodiment is a further limitation of the automobile instrument pointer crimping position control module described in Embodiment 1. In this embodiment, the control module also includes:

[0065] Display unit: display the pressure value collected by the pressure signal collection unit on the screen.

specific Embodiment approach 3

[0066] Specific Embodiment Three: This embodiment is a further limitation of the automobile instrument pointer crimping position control module described in Embodiment 1. In this embodiment, the control module further includes:

[0067] The parameter setting unit is used to provide an external data input port for setting parameters Fmax, Fmin, ΔF, T, F0 or sampling period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com