Mechanical side guide centering device

A centering device and mechanical technology, applied in the direction of guiding/positioning/aligning device, etc., can solve the problem that the rear guide roller cannot be opened quickly, and achieve the effect of stable and reliable belt threading, high efficiency, fast and precise mechanical centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

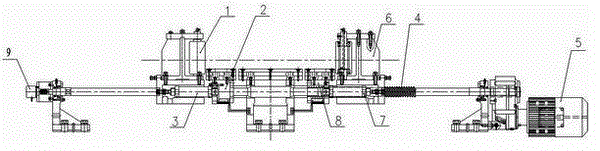

[0011] Such as figure 1 As shown, the left vertical guide roller seat 1 of the present invention is connected with the left screw nut seat 2 by the left cylinder 3, the right vertical guide roller seat 6 is connected with the right screw nut seat 8 by the right cylinder 7, and the left screw nut seat 2 , right screw mandrel nut seat 8 is connected with screw mandrel 4 respectively, and screw mandrel 4 and left screw mandrel nut seat 2, the screw thread direction of right screw mandrel nut seat 8 junctions are opposite, and screw mandrel 4 is connected with motor 5 by speed reducer; One end of the screw mandrel 4 is equipped with an absolute value encoder 9 for controlling the movement stroke of the left vertical guide roller base 1 and the right vertical guide roller base 6 . The motor 5 drives the left screw nut seat 2 and the right screw nut seat 8 to move relative to each other through the screw mandrel 4, so that after the left vertical guide roller seat 1 and the right ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com