a smoke oven

A smoked oven, smoked and roasted technology, applied in food ovens, baking, food science and other directions, can solve the problems of low production efficiency, high labor intensity, large floor space, etc., to facilitate installation and transportation, and improve work efficiency. Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

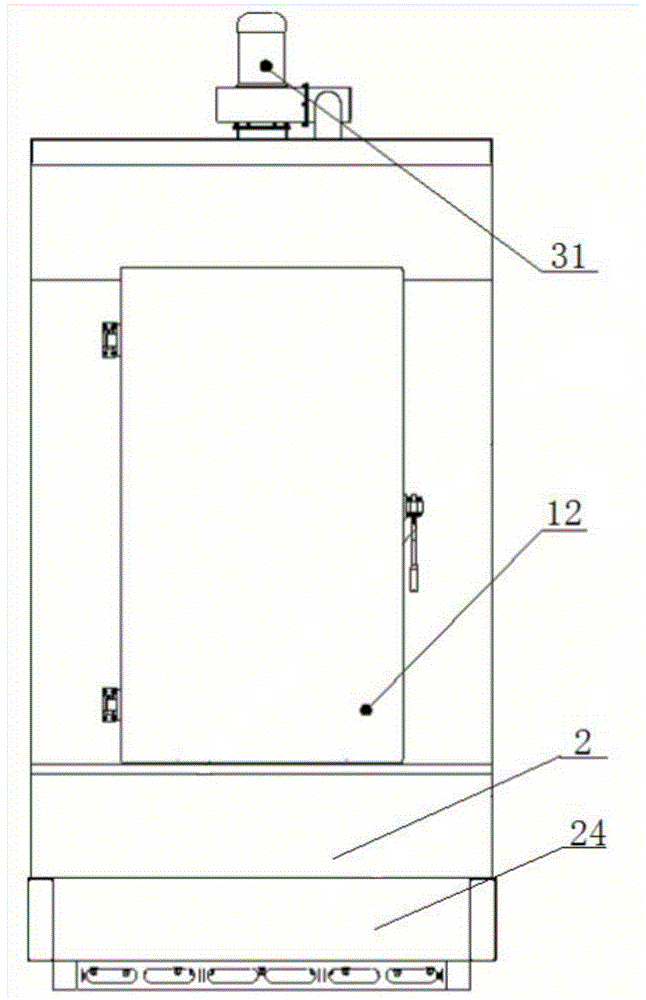

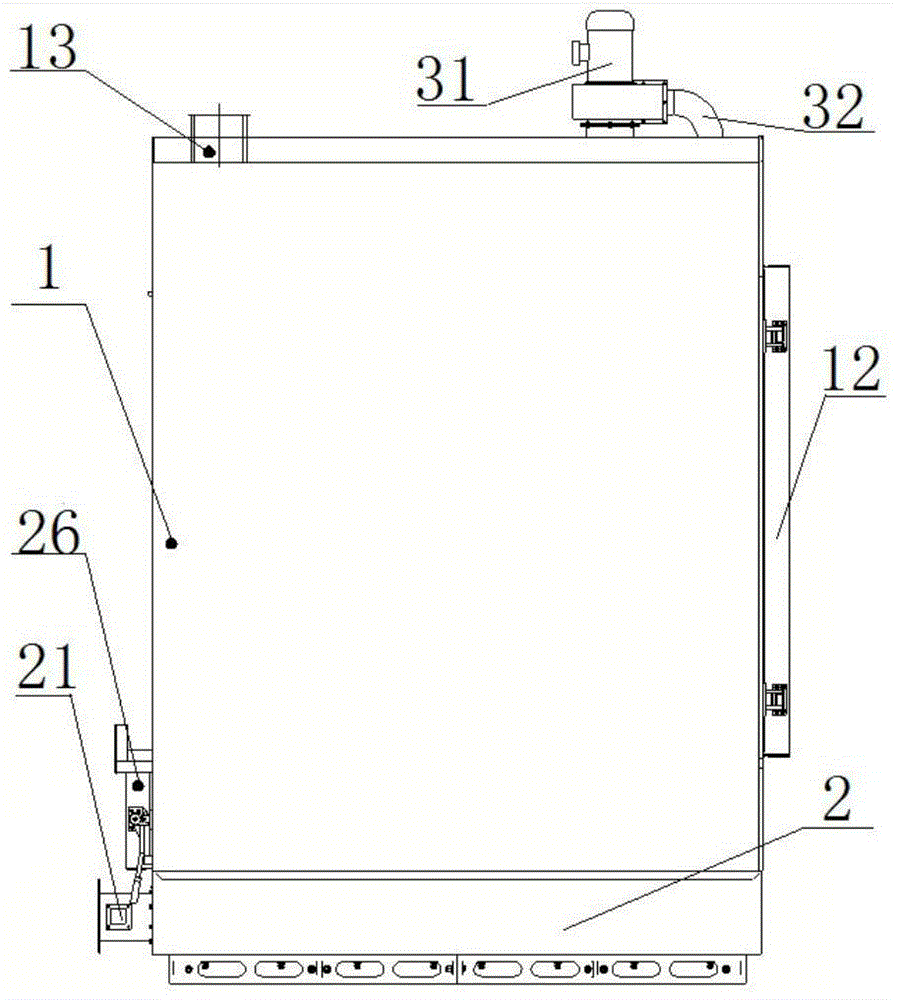

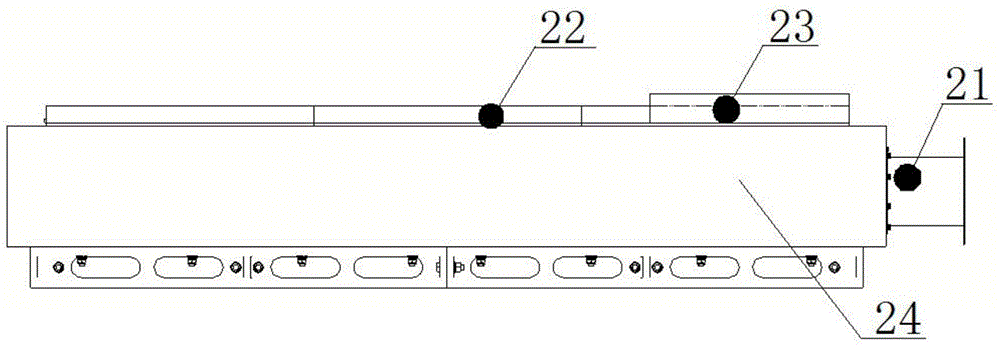

[0034] Such as figure 1 and figure 2 As shown, the present invention provides a smoking oven comprising: a hearth and a furnace body, the furnace body is arranged on the furnace hearth, the front wall of the furnace body is provided with a furnace door, the furnace body is provided with a circulating air duct, and the furnace body assembly is equipped with burner. Such as image 3As shown, the circulating air duct includes a fan, an exhaust pipe and an exhaust pipe. The fan is arranged on the furnace body, and the two exhaust pipes are installed on the air inlet of the fan through a branch pipe. The upper part; two rows of air pipes are installed on the air outlet of the fan through branch pipes, and the other end of the two rows of air pipes is arranged at the lower part of the furnace body; the top surface of the furnace body is also provided with a waste gas exhaust port. A circulating air duct is set in the furnace body, the air in the upper layer of the furnace body i...

no. 2 example

[0045] On the basis of the first embodiment, there are two exhaust pipes, and the air outlets of the two exhaust pipes are respectively arranged on both sides of the lower part of the furnace body. The preferred exhaust pipe is set in two, which can divert the hot gas flowing out of the fan, and then set the two air outlets of the exhaust pipe on both sides of the bottom of the furnace body, so that the gas discharged from the fan can be evenly distributed. Disperse into the furnace body to make the air mixing more uniform. In addition, an exhaust port is arranged on the top surface of the furnace body, which can exhaust the exhaust gas in the furnace body to the outside of the furnace body.

[0046] In the air circulation system, two exhaust pipes are installed on both sides of the upper part of the furnace body respectively, and several through holes are provided on the pipe wall at one end of the air inlet of the exhaust pipe to absorb the air in the furnace body. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com